7 Amazing Features of the Best 3D CNC Machine You Need to Know

In recent years, the manufacturing industry has witnessed a transformative shift thanks to the advancements in technology, particularly with the rise of the 3D CNC machine. According to a report by Grand View Research, the global CNC machine market size is projected to reach $100.51 billion by 2025, driven largely by the demand for precision and efficiency in production processes. This staggering growth is a testament to the critical role that 3D CNC machines play in modern manufacturing, enabling businesses to innovate and stay competitive. With capabilities ranging from intricate design replication to rapid prototyping, these machines not only streamline production but also enhance product quality.

In this blog, we will explore seven amazing features of the best 3D CNC machines that underscore their importance and the evolution of manufacturing as we know it.

Key Advantages of 3D CNC Machines in Modern Manufacturing

In today’s rapidly evolving manufacturing landscape, 3D CNC machines offer a range of key advantages that are revolutionizing production processes. One of the most significant benefits is their ability to enhance precision. Unlike traditional manufacturing methods, 3D CNC machines utilize computer-controlled technology to create intricate designs with unmatched accuracy. This precision not only improves the quality of the final products but also reduces material waste, leading to more efficient use of resources.

Another noteworthy advantage of 3D CNC machines is their versatility. These machines can work with a variety of materials, including metals, plastics, and wood, making them suitable for multiple industries. This flexibility allows manufacturers to experiment with different designs and products without investing in new tools for each material. Additionally, the rapid prototyping capabilities provided by 3D CNC machines enable companies to bring their ideas to life faster than ever, significantly speeding up the product development cycle and allowing for quick adjustments based on market demands.

Innovative Technology Driving Precision and Efficiency in 3D CNC

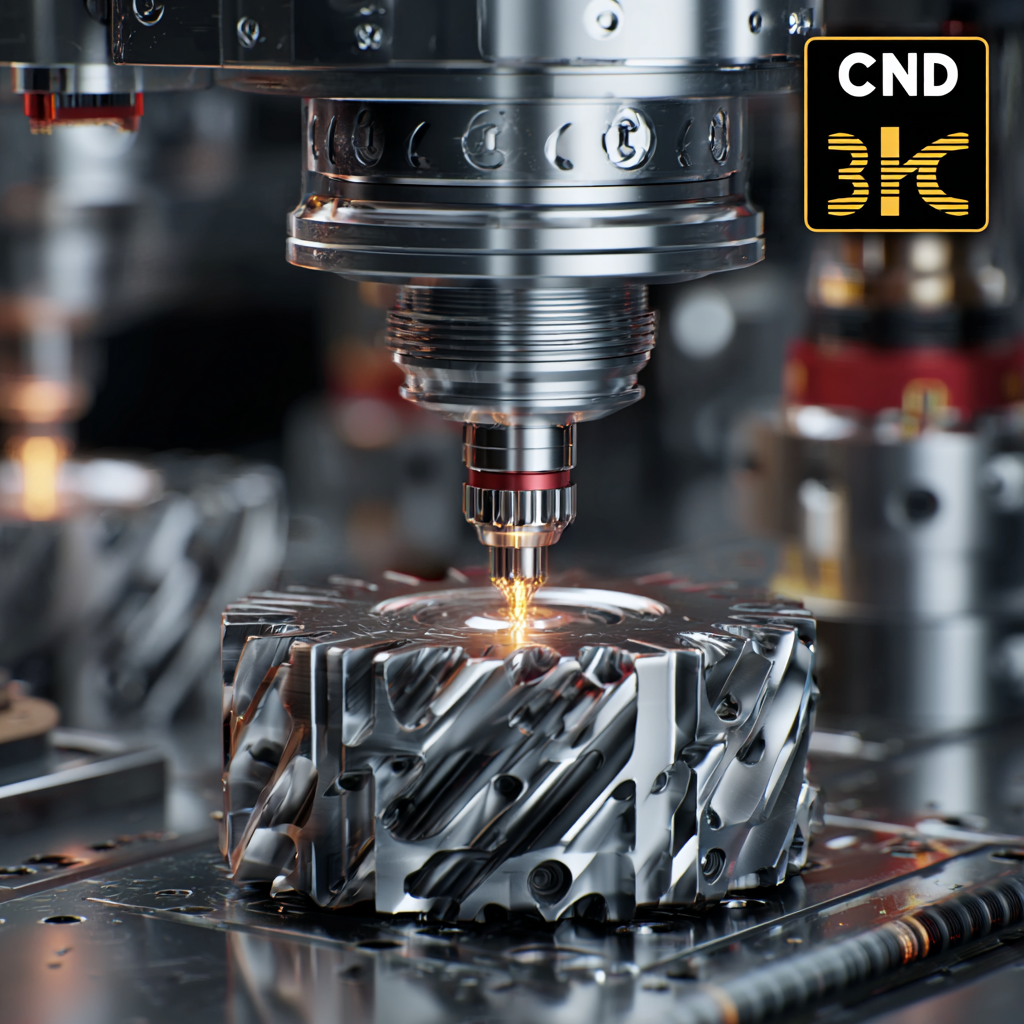

The world of manufacturing has been revolutionized by the advent of 3D CNC machines, which embody innovative technology that drives precision and efficiency. At the heart of this transformation is the automation of intricate processes, enabling manufacturers to achieve unprecedented levels of accuracy in their production runs. These machines utilize advanced software and hardware integration that not only streamlines operations but also minimizes human error, allowing for flawless engineering and design replication that was once thought impossible.

The world of manufacturing has been revolutionized by the advent of 3D CNC machines, which embody innovative technology that drives precision and efficiency. At the heart of this transformation is the automation of intricate processes, enabling manufacturers to achieve unprecedented levels of accuracy in their production runs. These machines utilize advanced software and hardware integration that not only streamlines operations but also minimizes human error, allowing for flawless engineering and design replication that was once thought impossible.

Another standout feature of the best 3D CNC machines is their ability to work with a diverse range of materials, from plastics to metals, with ease and precision. This versatility opens new avenues for creativity in design and production, giving businesses the flexibility to explore complex geometries and innovative forms. Additionally, the implementation of real-time monitoring systems ensures that every aspect of the machining process is optimized, resulting in reduced waste and enhanced productivity. Together, these technological advancements are transforming the landscape of manufacturing, making it more efficient and precise than ever before.

Understanding the Versatility of 3D CNC Machines Across Industries

3D CNC machines have revolutionized manufacturing across various industries, showcasing their remarkable versatility. These advanced machines can produce intricate designs and complex shapes with precision that traditional methods struggle to achieve. In industries such as automotive, aerospace, and medical, the ability to create customized and lightweight components is crucial. For instance, automotive manufacturers utilize 3D CNC technology to streamline production processes and reduce waste, ultimately leading to cost savings and enhanced performance.

Moreover, in the medical field, 3D CNC machines are transforming the way prosthetics and implants are made. The precision of these machines allows for the creation of highly personalized solutions that cater to the unique anatomical needs of patients. Additionally, industries like fashion and art benefit from the creative potential of 3D CNC technology, allowing designers to push the boundaries of their imagination. As these machines continue to evolve, their applications are expected to expand, making them indispensable tools in modern manufacturing and design.

How 3D CNC Machines Enhance Design Flexibility and Creativity

One of the most significant advantages of 3D CNC machines is their ability to enhance design flexibility. Unlike traditional machining methods, which often require extensive setup and tooling changes for different projects, 3D CNC technology allows designers to pivot their ideas rapidly. With advanced software integration, it’s easy to modify designs on the fly, enabling a more iterative approach. This is particularly beneficial for industries that rely on rapid prototyping, where speed and adaptability are essential.

Moreover, 3D CNC machines empower creativity by enabling the production of complex geometries and intricate details that would be nearly impossible to achieve manually. Designers can experiment with unique shapes, patterns, and textures, knowing that their visions can be accurately brought to life in tangible form. The precision of CNC technology ensures that even the most elaborate designs are executed flawlessly, inspiring innovation and encouraging exploration of unconventional concepts. This newfound creative freedom has revolutionized fields such as product design, architecture, and even art, setting the stage for endless possibilities in the realms of design and manufacturing.

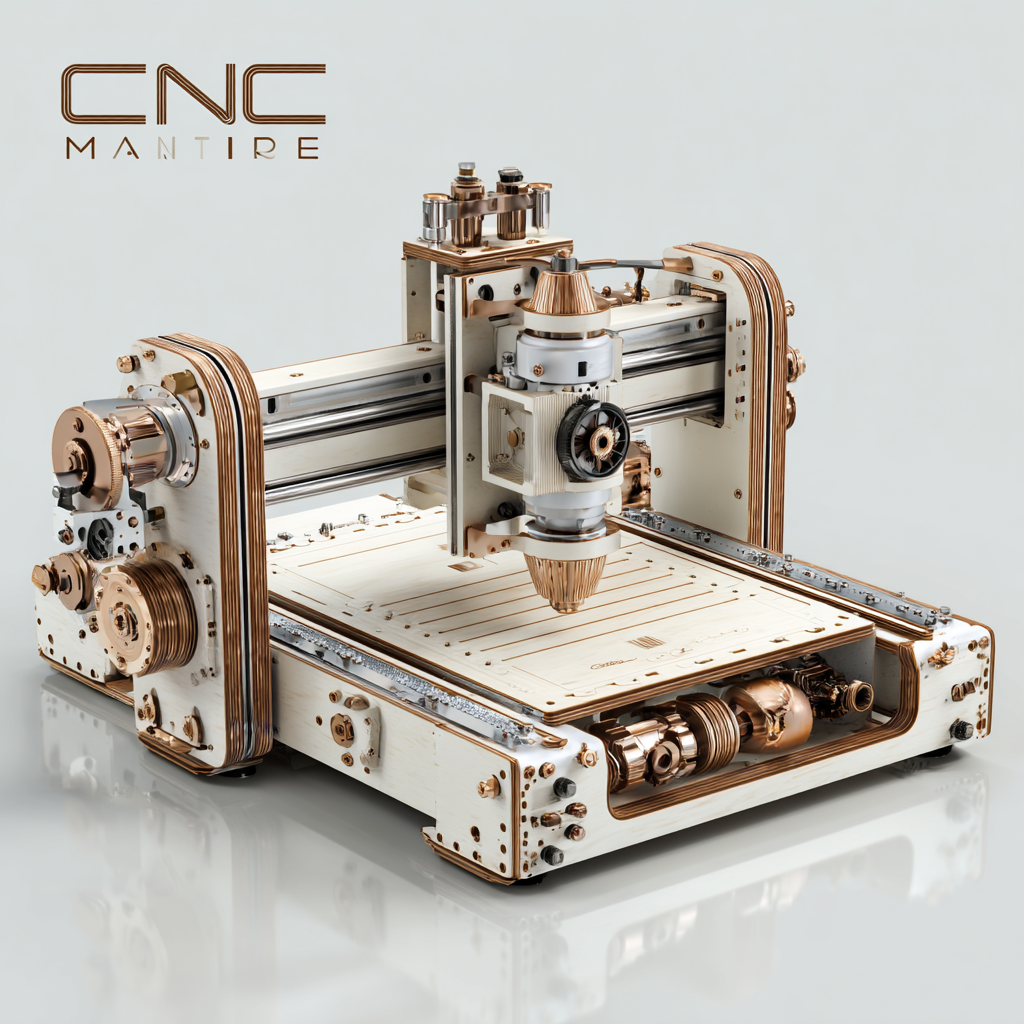

7 Amazing Features of the Best 3D CNC Machine

Exploring the Economic Benefits of Investing in a 3D CNC Machine

Investing in a 3D CNC machine can bring significant economic benefits to businesses of all sizes. These advanced machines enhance production efficiency,

reduce material waste, and minimize labor costs. By automating intricate design processes, companies can produce high-quality components rapidly, allowing them to meet client demands without compromising precision.

This efficiency leads to shorter turnaround times, ultimately improving cash flow and profitability.

Tip: Regular maintenance of your 3D CNC machine is crucial to prolonging its lifespan and ensuring optimal performance.

Establishing a routine check-up schedule can prevent costly breakdowns and keep your production line running smoothly.

Moreover, the versatility of 3D CNC machines allows businesses to diversify their product offerings. With the ability to work with various materials, companies can branch into new markets and provide customized solutions that cater to specific customer needs.

This flexibility not only attracts a wider clientele but also encourages innovation within the organization.

Tip: Invest in training your staff to maximize the use of 3D CNC technology. Skilled operators can unlock the full potential of the machine, leading to better quality outputs and driving business growth.