What is an Aluminum Composite Panel Manufacturer?

aluminum composite panel manufacturers play a crucial role in modern construction. These panels offer durability and aesthetic appeal. According to John Smith, an expert in the construction materials industry, "The versatility of aluminum composite panels is unparalleled." This statement highlights the significance of these materials.

Aluminum composite panels consist of two thin layers of aluminum enclosing a non-aluminum core. This structure provides strength while keeping the panels lightweight. Many manufacturers focus on innovation, but quality tends to vary. It's essential to choose manufacturers that prioritize both sustainability and design.

In today's competitive market, aluminum composite panel manufacturers must adapt to changing demands. While some lead in technology, others struggle to keep up. This gap can affect project outcomes. Careful selection of panels ensures that architectural visions come to life without compromising on quality.

What is an Aluminum Composite Panel and Its Advantages?

Aluminum composite panels, often called ACPs, are a modern building material. They consist of two thin layers of aluminum enclosing a non-aluminum core. This structure gives them unique advantages in architecture and design.

One major benefit of aluminum composite panels is their lightweight nature. Despite their low weight, they are incredibly strong. They resist dents and impacts, making them suitable for high-traffic areas. Additionally, the panels are known for their durability. They can withstand harsh weather conditions and do not easily fade or corrode. This longevity reduces maintenance needs, which can be a significant advantage over time.

ACPs are also versatile in appearance. They can mimic the look of natural materials like wood or stone. However, they may not always achieve the same aesthetics as their natural counterparts. The finish can vary, and finding the right texture might require some effort. Decisions must be made carefully to ensure the desired outcome. In some cases, installation can be tricky, requiring skilled labor for proper alignment.

The Role of Aluminum Composite Panel Manufacturers in Construction

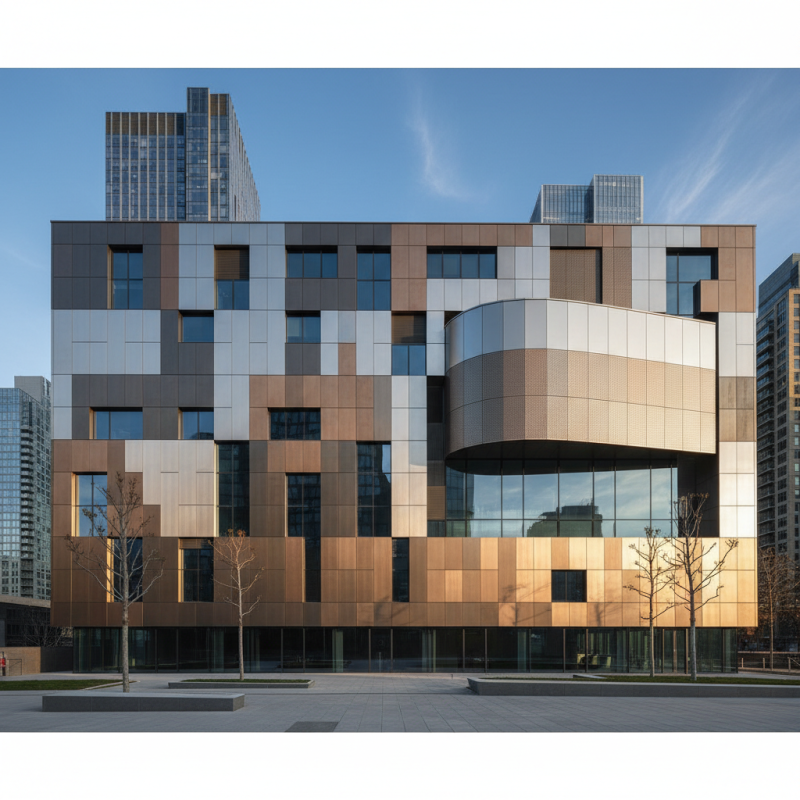

Aluminum composite panel manufacturers play a crucial role in modern construction. These panels are lightweight yet sturdy. They consist of two thin layers of aluminum enclosing a non-aluminum core. This makes them ideal for building facades, interior walls, and signage. Their versatility is impressive, providing insulation and soundproofing qualities. Many architects prefer these panels for their aesthetic appeal and durability.

However, the manufacturing process has its challenges. Ensuring quality control can be tricky. Some manufacturers may cut corners on materials to reduce costs. This can lead to structural weaknesses. Additionally, the sourcing of raw materials impacts the overall sustainability of the product. It's vital for manufacturers to balance cost with quality. Striking this balance can be a tough task.

In construction, the choice of panels influences both appearance and function. Some projects may suffer if low-quality panels are used. It's essential for builders to collaborate closely with manufacturers. Communication is key to achieving desired outcomes. This relationship can enhance the final product, ensuring it meets safety standards and client expectations. A thoughtful approach is essential in this industry.

Key Manufacturing Processes for Aluminum Composite Panels

Aluminum composite panels (ACP) are widely used in construction and design. They consist of two thin layers of aluminum enclosing a non-aluminum core. The manufacturing process is crucial in determining the quality and durability of these panels.

Key manufacturing processes include panel preparation and assembly. Initially, aluminum sheets are cleaned and pretreated. This step ensures strong adhesion between layers. During assembly, the core material is inserted between the aluminum sheets. Adhesives or heat are typically used to bond these layers. Equipment must be calibrated accurately to avoid defects. A slight misalignment can lead to serious flaws in the final product.

Tips: Always check the quality of raw materials. Poor materials can compromise the entire project. Regular maintenance of machinery is also essential. Neglected equipment may yield inconsistent results.

After assembly, the panels undergo finishing treatments. Coatings may be applied for added protection. Colors are often added during this stage, enhancing aesthetic appeal. Testing is crucial here. Unfinished panels may not meet durability standards.

In summary, understanding these processes helps to address concerns during production. Regular evaluations can improve the overall quality of aluminum composite panels.

Market Trends and Future Projections in Aluminum Composite Panel Industry

The aluminum composite panel (ACP) industry is experiencing significant growth. A recent market report projects a compound annual growth rate (CAGR) of 6.5% from 2023 to 2030. This growth is driven primarily by the increasing demand for lightweight materials in construction and automotive sectors. The trend towards green buildings also contributes to this expansion. Developers prioritize energy efficiency and sustainability.

Performance and aesthetic appeal of aluminum composite panels play a huge role in their popularity. These panels offer excellent insulation and fire resistance, making them ideal for modern architecture. Data shows that 70% of architects favor ACP for their projects. However, there are challenges. Issues regarding environmental impact and recycling of these materials must be addressed. Sustainability is becoming a crucial factor in the design process.

**Tips:** Focus on suppliers who prioritize eco-friendly practices. It’s important to inquire about the sourcing of their materials. Understanding local regulations on panel use is also vital. Ensure all materials comply with safety standards. Always weigh the pros and cons. The market is evolving, and staying informed is essential for making wise choices.

Certifications and Standards for Quality in Aluminum Composite Manufacturing

In the aluminum composite panel (ACP) industry, certifications and standards play a crucial role. They ensure the integrity and reliability of products. Manufacturers often pursue ISO certification, which demonstrates a commitment to quality management. According to a recent market report, over 70% of consumers prioritize certified products. This trend highlights the importance of industry standards.

Quality assurance in ACP manufacturing is multi-faceted. Many manufacturers adhere to ASTM standards, which outline material properties and performance criteria. Compliance with these standards can enhance product durability. Reports indicate that ACPs meeting these benchmarks have a lower failure rate. Yet, some manufacturers struggle with consistent compliance, leading to potential quality issues.

The significance of local regulations cannot be overlooked. Regions such as Europe have stringent fire safety standards for ACPs. These regulations drive innovation and improve safety features. However, not all manufacturers stay updated with these changing standards. This gap can lead to a significant decline in consumer trust and product reliability. Being aware of certifications is vital for both manufacturers and end-users in this evolving market.