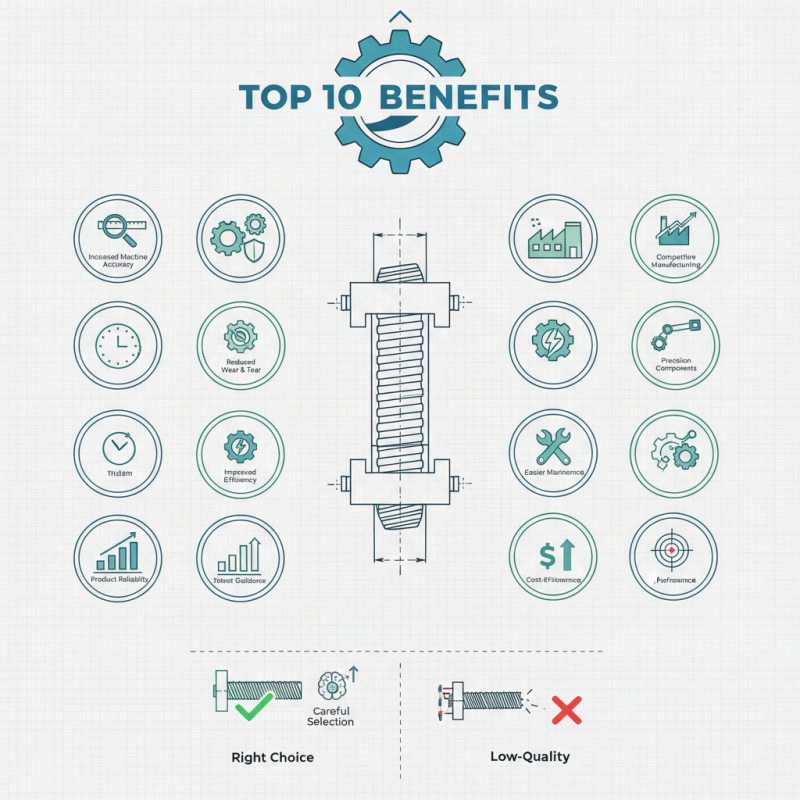

Top 10 Benefits of Using a Ball Screw for Sale

As manufacturing becomes more competitive, the demand for precision components grows. A ball screw for sale provides numerous advantages that can enhance product efficiency and reliability. According to a report by the Machine Tool Engineering Association, utilizing ball screws can improve machine accuracy by up to 70%. This significant increase positions them as a crucial element in modern engineering processes.

Industry expert Dr. Emily Tran, a leading figure in motion control systems, emphasizes, "The integration of a ball screw can drastically reduce operational wear and tear." This statement highlights the durability and longevity of ball screws in demanding applications. Yet, not every option on the market meets the required quality standards. The presence of low-quality ball screws can lead to inefficient performance, which is an important factor for companies to consider.

Choosing the right ball screw for sale is essential. Companies must evaluate their specific needs against available products. A thoughtful approach can lead to enhanced machine performance. However, overlooking critical factors may result in unanticipated failures. Therefore, careful selection and expert guidance are vital in optimizing the use of ball screws in various applications.

Understanding Ball Screws: Mechanics and Design

Ball screws are essential components in various mechanical systems. They convert rotational motion into linear motion. Understanding their mechanics and design can help you appreciate their efficiency. A ball screw consists of a screw, nut, and ball bearings. This design reduces friction between moving parts. Less friction means longer life and better performance.

When choosing a ball screw, consider the load it will bear. Overloading can lead to unexpected failures. Pay attention to the precision level required for your project. Even small errors can compound. Make sure to select the right diameter and pitch for your application.

Tip: Regular maintenance of your ball screw will prolong its life. Check for wear and replace parts as needed. Tip: Clean the screw and nut regularly to avoid debris buildup. This simple step can prevent costly repairs. A properly maintained ball screw operates at peak efficiency. Don't overlook the importance of choosing the correct lubricants.

Enhanced Efficiency and Precision in Motion Control

Ball screws are essential components in modern motion control systems. They offer enhanced efficiency and precision, reducing energy consumption significantly. When used in machinery, they provide smooth motion and accurate positioning. This remarkable efficiency stems from the screw-and-nut design, which minimizes friction. As a result, less effort is required to achieve desired movements.

Precision is another major advantage. Ball screws allow for fine adjustments in positioning. This is crucial in applications like robotics or CNC machining. Small errors can lead to significant issues down the production line. Despite their benefits, ball screws can sometimes require careful maintenance. Dust and debris can affect their performance, so regular checks are vital. Users need to be diligent about upkeep to ensure optimal function.

The need for precision doesn’t stop at installation. Ongoing performance assessment is key. Users must evaluate how well their system operates over time. Any deviation from expected outcomes can signal that something is wrong. Being proactive in these areas can save time and resources in the long run.

Durability and Longevity of Ball Screw Systems

Ball screw systems are renowned for their durability and longevity. These components can achieve a lifespan exceeding 15,000 kilometers of linear motion. The ability to withstand heavy loads while maintaining precision makes them ideal for various applications, from CNC machines to robotics.

A recent industry report highlights that ball screws have up to 90% efficiency in converting rotary motion to linear motion. This efficiency minimizes friction, leading to lesser wear and tear. However, inadequate maintenance can negate these benefits. Proper lubrication is crucial; dry ball screws can suffer rapid degradation.

Moreover, environmental factors can impact longevity. Exposure to extreme temperatures or corrosive substances may harm these systems. Users must remain vigilant. Regular inspections and timely replacements can help maintain performance over time. Such proactive measures can extend the life of ball screw systems significantly. While they are designed for longevity, neglect can lead to unexpected failures.

Applications of Ball Screws in Various Industries

Ball screws are essential components in various industries, offering precision and efficiency. In manufacturing, they enhance CNC machine performance. A study shows that ball screws can improve machining accuracy by up to 30%. This is vital when producing intricate components. Moreover, ball screws reduce friction, leading to longer tool life and better surface finishes.

The automotive sector relies heavily on ball screws. For instance, they are critical in electric power steering systems. Their ability to transform rotary motion into linear movement allows for smoother handling. According to industry reports, the adoption of ball screws in automotive applications has grown by 15% annually. However, they require careful design to avoid potential backlash, which can hinder performance.

In robotics, ball screws play a crucial role in movement. They enable precise positioning of robotic arms in assembly lines. However, the complexity of integrating ball screws can be challenging. Engineers must consider load requirements and thermal expansion. Failure to do so may lead to inefficiencies. The balance between precision and design complexity remains a topic of ongoing discussion in the engineering field.

Cost-Effectiveness of Ball Screw Solutions in Manufacturing

The cost-effectiveness of ball screw solutions in manufacturing is compelling. According to industry reports, implementing ball screws can improve efficiency by 20-30%. This translates to significant savings in operational costs. For instance, reduced friction in ball screws means less energy consumption. It helps optimize overall production efficiency.

Moreover, ball screws offer a longer lifespan compared to traditional lead screws. A well-maintained ball screw can last over 10 years. This durability reduces replacement costs and downtime. However, the initial investment can be a hurdle for some manufacturers. It requires careful consideration and evaluation of long-term benefits versus immediate expenditures.

Maintenance is another aspect to reflect on. While ball screws generally require less frequent servicing, neglect can lead to costly failures. Understanding the balance between maintenance and replacement remains crucial. Manufacturers must weigh the upfront costs against potential savings over time.