10 Reasons the Best CNC Laser Engraver Will Transform Your Business

In today's rapidly evolving manufacturing landscape, the integration of advanced technologies is crucial for business growth and competitive advantage. One such transformative technology is the CNC laser engraver, which has been reported to increase production efficiency by up to 30% while significantly reducing labor costs (Source: Industry Week). With the global laser engraving market projected to reach $5 billion by 2026 (Source: Market Research Future), businesses cannot afford to overlook the impact of adopting CNC laser engraver systems. This advanced tool not only enhances precision and customization but also opens up new avenues for creativity and innovation across various industries, from woodworking to metal fabrication.

In this blog, we will explore ten compelling reasons why investing in the best CNC laser engraver can revolutionize your business operations and set you apart in a competitive marketplace.

The Impact of CNC Laser Engraving on Business Efficiency in 2025

The impact of CNC laser engraving on business efficiency is set to be

transformative by 2025. As industries increasingly adopt advanced machinery, the laser processing equipment

market is projected to experience substantial growth, with an anticipated rise from $28.51 billion in 2025 to $64.39 billion

by 2032 at a remarkable CAGR of 12.3%. This rapid expansion

is driven by the need for precision, speed, and cost-effectiveness in manufacturing processes, making CNC laser

engravers essential tools for modern businesses.

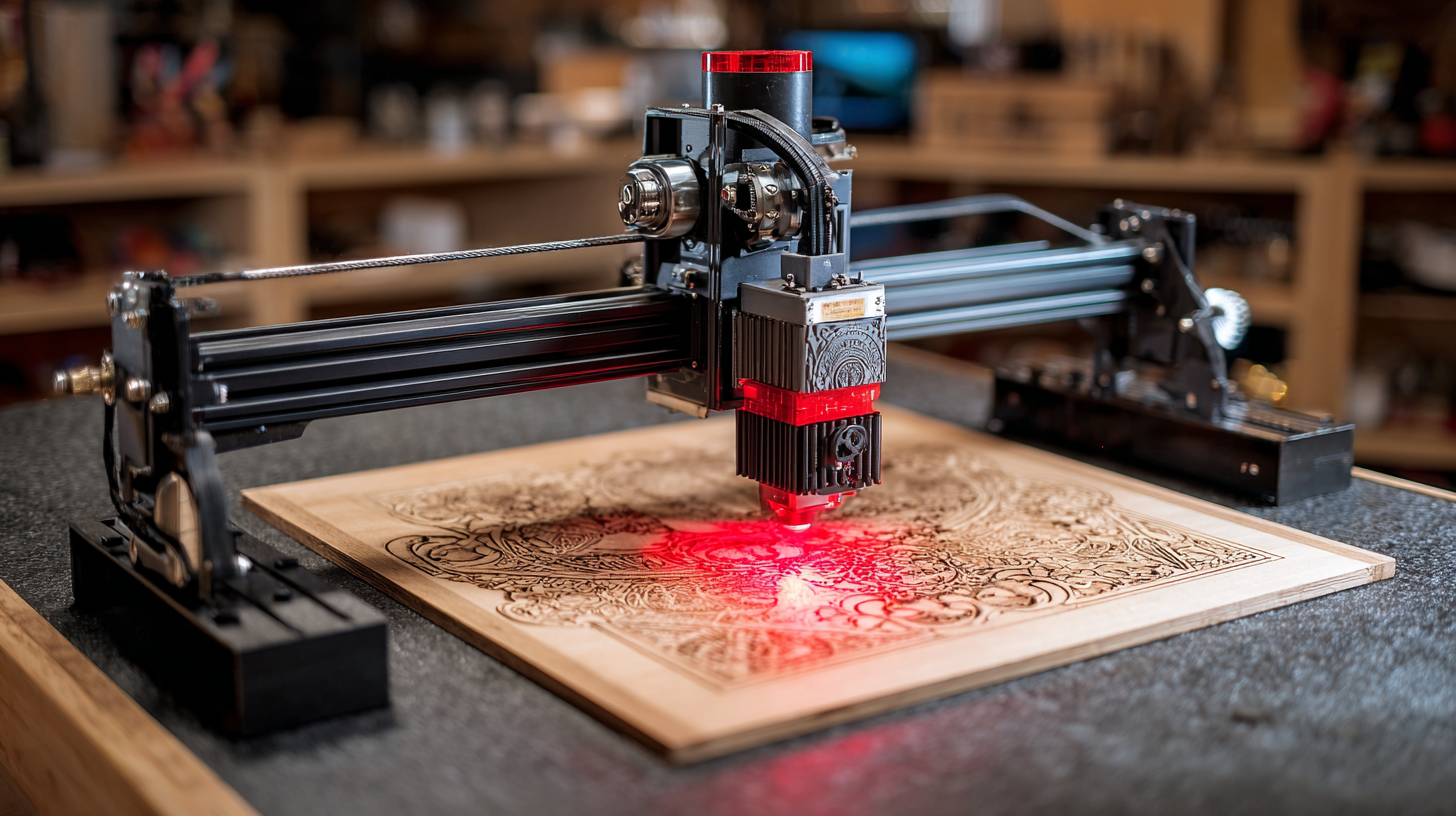

With the capabilities of laser engraving technologies, companies can enhance their product offerings through

customization and innovation. The ability to engrave intricate designs on various materials not only improves

aesthetic appeal but also allows for high levels of personalization, which is increasingly demanded by consumers.

As businesses integrate these technologies, operational efficiencies are improved, leading to reduced overhead

costs and increased productivity. In an era where competition is fierce, adopting state-of-the-art

CNC laser engravers will undoubtedly empower businesses to stay ahead in the

market and respond swiftly to changing consumer preferences.

Key Technological Innovations in CNC Laser Engraving for Future Growth

The CNC laser engraving industry is experiencing rapid growth, driven by key technological innovations and significant market opportunities. With China's position as the largest industrial laser market, the sector's market size is projected to reach approximately 89.9 billion yuan by 2024. Advancements in laser processing equipment have not only improved efficiency and precision but also made it possible for businesses to customize products at unprecedented scales, enhancing overall competitiveness.

Recent data highlights an impressive forecast for the laser engraving machine market. Valued at approximately $312 million in 2022, this sector is expected to soar to nearly $678 million by 2030, reflecting a compound annual growth rate (CAGR) of 10.5% from 2024 to 2030. These statistics underscore the transformative potential of CNC laser engravers, as they enable companies to innovate and expand their product offerings with sophistication and adaptability, crucial for meeting evolving consumer demands.

How to Choose the Right CNC Laser Engraver for Your Business Needs

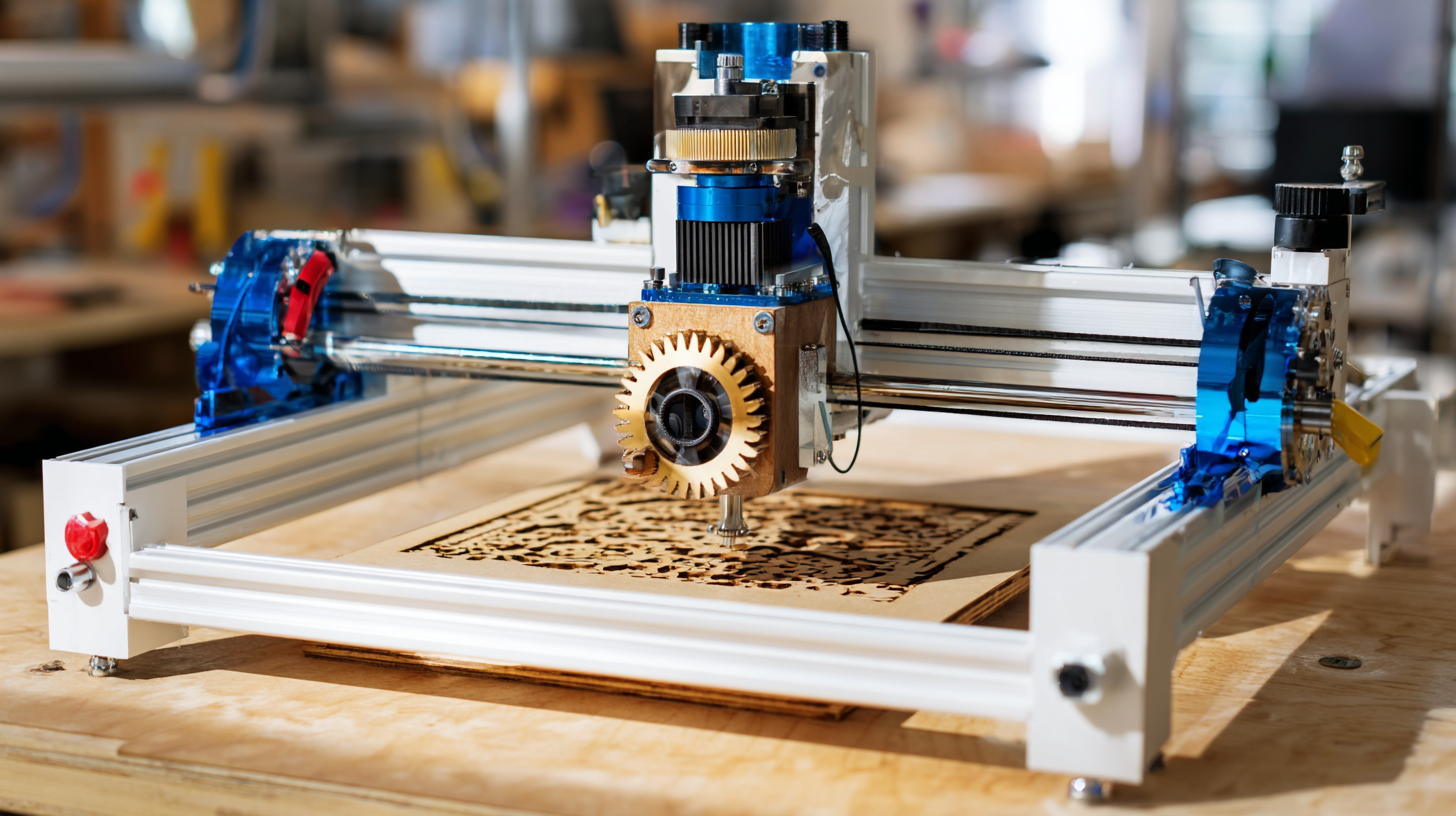

Choosing the right CNC laser engraver for your business needs can significantly enhance your productivity and output quality. First and foremost, you should assess the materials you plan to work with. Different laser engravers are optimized for specific materials, such as wood, acrylic, glass, or metal. Understanding your primary products will help you select a machine suited to those materials, ensuring effective engraving and minimal waste.

Another critical factor is the size of the workspace. Consider the dimensions of the items you will engrave, as well as the volume of production. A larger engraving area allows for the potential to work on bigger pieces or create multiple items simultaneously, enhancing your efficiency. Additionally, look into the machine's laser power and speed settings.

Higher wattage typically means faster engraving times and the ability to cut through thicker materials, making it an essential consideration for businesses aiming for high output. By aligning these features with your business objectives, you can make an informed choice that propels your company forward.

Maximizing Profits: Integrating CNC Laser Engraving into Your Operations

The integration of CNC laser engraving technology into your operations can dramatically enhance your productivity and profitability. According to a report from the MarketsandMarkets research group, the global laser engraving market is expected to grow from USD 4.6 billion in 2020 to USD 5.9 billion by 2025, at a compound annual growth rate (CAGR) of 5.2%. This growth is driven not only by advanced engraving capabilities but also by the ability to optimize production speed and efficiency. Businesses that adopt CNC laser systems can cut lead times significantly, enabling quicker turnaround on projects and greater customer satisfaction.

Moreover, the precision offered by modern CNC laser engravers opens new avenues for customization, allowing businesses to cater to niche markets and unique customer demands. A study by Grand View Research highlights that personalized products in sectors like gifts and promotional items have gained immense popularity, with the market size expected to reach nearly USD 60 billion by 2025. By incorporating CNC laser engraving into your business model, you can tap into this burgeoning trend, creating personalized solutions that not only attract attention but also command higher prices, amplifying your profit margins.

Impact of CNC Laser Engraving on Business Profitability

Future Trends: What to Expect in CNC Laser Engraving Technology by 2025

As we look towards 2025, the CNC laser engraving technology is poised for remarkable advancements that will redefine the manufacturing landscape. One significant trend is the increased integration of artificial intelligence in CNC systems. This innovation will enable machines to learn from previous jobs, optimizing engraving paths and minimizing material waste. Businesses can expect higher precision and efficiency, allowing them to meet the growing demands for customized products at competitive prices.

Another exciting development is the emergence of more compact and versatile laser engravers. As technology progresses, manufacturers are creating machines that are not only smaller and easier to operate but also capable of handling a wider variety of materials. This versatility will empower businesses to expand their offerings, tapping into niche markets that require unique engraving capabilities. Moreover, the decrease in machine size coupled with enhanced portability means that laser engravers can be utilized in diverse environments, from small workshops to on-site events, thus broadening the scope for creative applications.