Unlocking Precision: A Comprehensive Guide to the Best CNC Machine for Home Use with Technical Specs!

In recent years, the demand for CNC machines for home use has seen a significant surge, driven by the rise of DIY enthusiasts and small business owners seeking to enhance their production capabilities. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach USD 100 billion by 2025, growing at a CAGR of 7.5% from 2020. This growth highlights the increasing accessibility and affordability of CNC technology, paving the way for hobbyists and professionals alike to invest in precision machinery for their own workshops. As more individuals explore the potential of CNC machines for crafting intricate designs and executing complex projects, understanding the features, specifications, and applications of these devices becomes paramount. Our comprehensive guide will help unlock the precision of CNC machines for home use, providing valuable insights into the best options available today.

Understanding CNC Machines: Key Features for Home Use

CNC machines have revolutionized the way hobbyists and small businesses approach fabrication and manufacturing at home. Understanding the key features of these machines is essential for selecting the right model tailored to personal needs. A recent report from MarketsandMarkets estimates that the global CNC machine market is projected to reach $100 billion by 2025, highlighting the significant growth and demand for precise machining solutions in the home workshop sector.

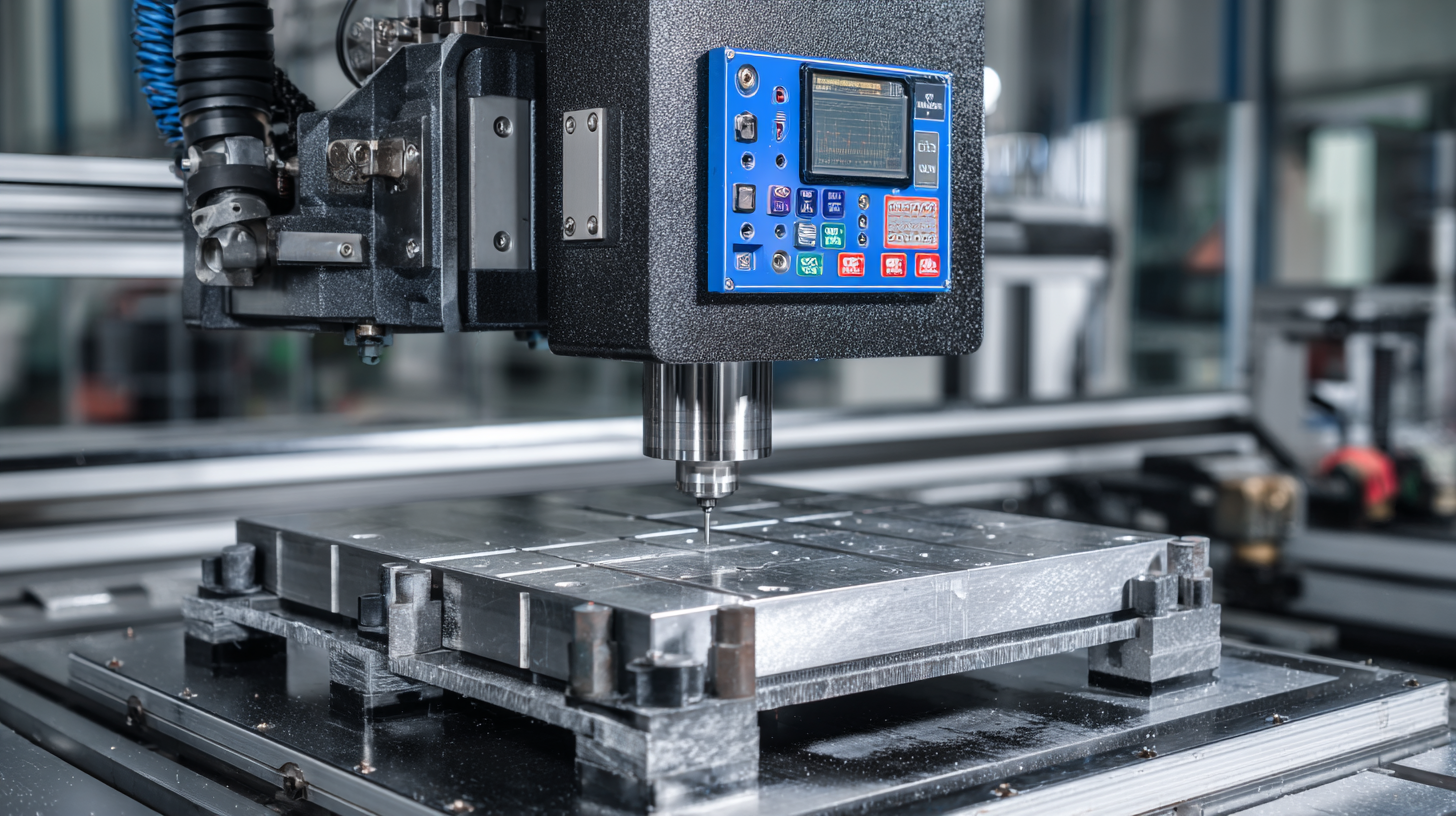

When evaluating a CNC machine for home use, consider specifications such as build volume, accuracy, and the types of materials it can handle. Machines with a build volume of at least 300mm x 300mm are essential for versatile projects, as they can accommodate a range of materials from wood to aluminum. High precision is also critical; machines with a repeatability of ±0.01 mm or better are often favored.

Additionally, ease of use features such as intuitive software integration and support for various file types can greatly enhance the user experience. According to a survey by Techsci Research, 70% of CNC machine users cite ‘ease of use’ as a top priority when choosing their ideal machine for home applications.

As the CNC landscape continues to evolve, understanding these key features will empower users to unlock the full potential of their machines, enabling them to produce detailed designs and innovative projects right from their home workshops.

Top 5 CNC Machines: Performance Metrics You Should Know

When it comes to choosing the best CNC machine for home use, understanding the performance metrics is key.

The right machine can transform your projects, whether you're creating intricate woodwork, metal parts, or even customized components.

The top five CNC machines we've selected offer a range of technical specifications that cater to different user needs, from hobbyists to more advanced makers.

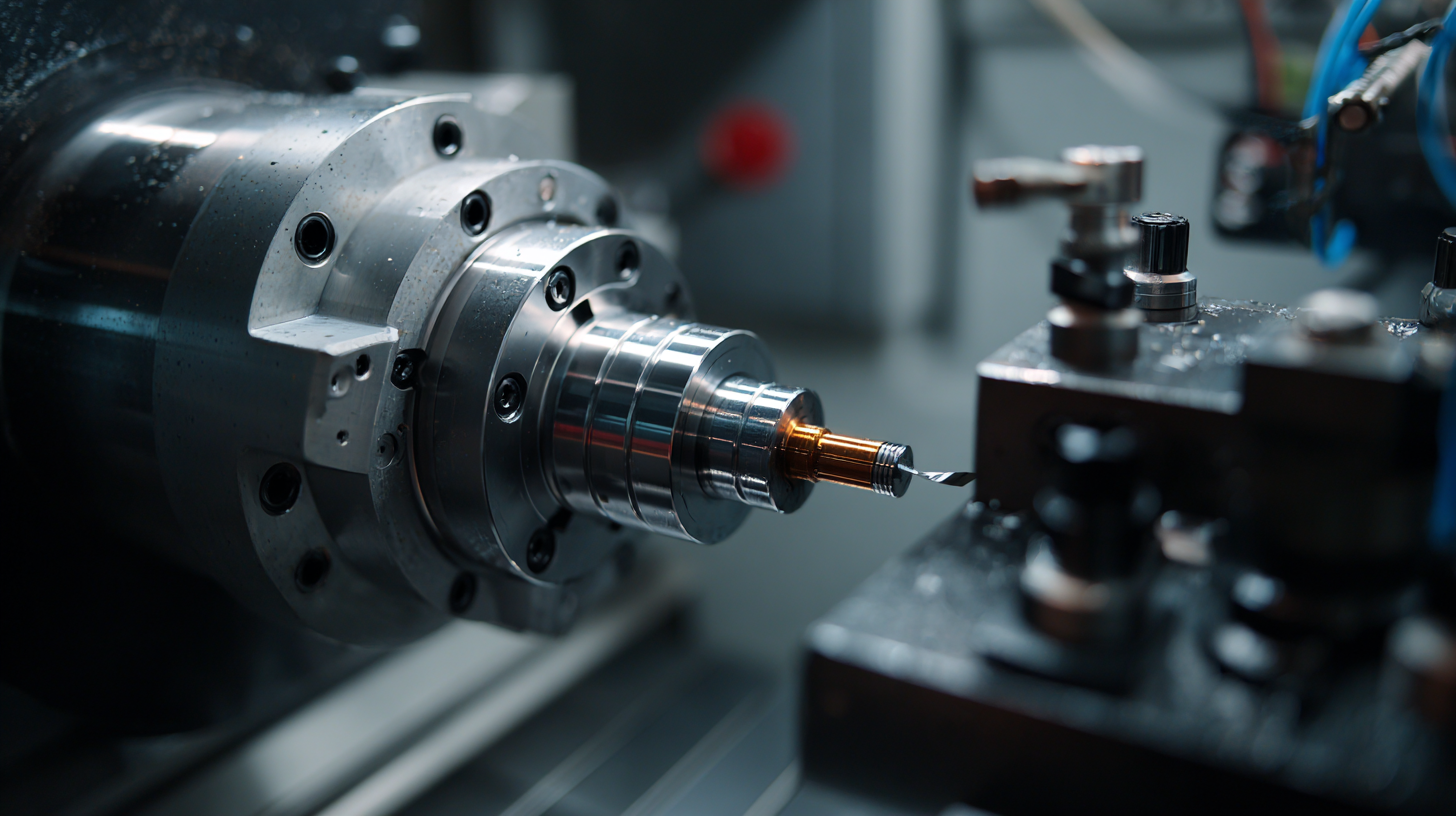

First, consider the spindle speed, which is crucial for determining the cutting efficiency.

A higher spindle speed means the machine can work through materials quickly, resulting in better surface finishes.

Additionally, the work area dimensions should be factored in, as they dictate the maximum size of projects you can undertake.

Look for machines that offer at least a 300 mm x 300 mm workspace to accommodate various projects.

Another essential performance metric is the machine's repeatability and accuracy.

A precision CNC machine should maintain tolerances within ±0.01 mm, ensuring that each cut is consistent and reliable.

Lastly, feed rate flexibility is vital—machines that allow you to adjust feed rates according to material types can greatly enhance your project outcomes.

Evaluating these performance metrics will help you make an informed decision and unlock the full potential of your CNC projects at home.

Comparison of Cost vs. Quality: Which CNC Machines Deliver Value?

When considering CNC machines for home use, it's essential to weigh the cost against the quality of the machine. Many hobbyists and small business owners find themselves at a crossroads between budget-friendly options and models that offer superior craftsmanship. The best value comes from machines that strike a balance between affordability and features, ensuring reliability and precision for various projects.

One tip for buyers is to research not only the upfront costs but also the long-term expenses associated with maintenance and parts replacement. Investing in a slightly more expensive machine that has a good track record for durability can save money over time. Additionally, consider the quality of customer support offered by the manufacturer, as this can greatly influence your satisfaction and ability to troubleshoot issues.

Another critical factor to consider is the machine's capabilities and the materials it can handle. Ensure that the CNC machine you select aligns with your specific needs, whether it's for woodworking, metalworking, or crafting. Features like ease of use, software compatibility, and the machine’s precision should also factor into your decision, as these can significantly impact the quality of your final products.

Technical Specs Breakdown: What to Look for in a CNC Machine

When selecting a CNC machine for home use, understanding the technical specifications is crucial for making an informed decision. Key specs to consider include the machine's type—whether it’s a router, mill, or laser cutter—each serving distinct purposes. For example, router machines are best for woodworking, while laser cutters excel at precision engraving on various materials. Additionally, consider the machine's build volume, which indicates the maximum size of workpieces it can handle. A larger build volume allows for greater versatility in projects, but might also require more space.

Another vital specification is the motor power and spindle speed, which directly affect cutting performance and material compatibility. Higher spindle speeds are essential for achieving fine details in softer materials but might not be necessary for tougher materials, where torque becomes more critical. Furthermore, assess the machine's precision, typically measured in resolution, which can significantly influence the quality of the finished product. Features such as auto-leveling systems, tool changers, and user-friendly interfaces can also enhance usability, making the CNC machine better suited for both beginners and experienced users alike.

Unlocking Precision: A Comprehensive Guide to the Best CNC Machine for Home Use with Technical Specs!

| Feature | Value |

|---|---|

| Work Area (X x Y x Z) | 300mm x 300mm x 100mm |

| Max Spindle Speed | 24000 RPM |

| Drive Type | Stepper Motor |

| Controller Type | USB Controller |

| Materials Supported | Wood, Acrylic, Soft Metals |

| Software Compatibility | Mach3, GRBL, others |

| Dimensions | 600mm x 600mm x 600mm |

| Weight | 25 kg |

| Power Supply | 100-240V AC |

| Price Range | $500 - $1500 |

Safety Standards and Certifications for Home CNC Usage

When considering the integration of a CNC machine into your home workshop, understanding safety standards and certifications is paramount. Home CNC usage often comes with unique risks, from moving parts to sharp tools. To mitigate these hazards, it's essential to select machines that comply with established safety regulations. Look for certifications from reputable organizations such as ANSI (American National Standards Institute) or UL (Underwriters Laboratories), which indicate that the machine meets specific safety criteria designed to protect users.