Unlocking Precision Best Engraving Machine Specifications and How to Choose the Perfect Fit

As the demand for customized products and intricate designs continues to grow across various industries, the significance of precision in engraving technology cannot be overstated. An engraving machine is a pivotal tool that enables businesses to achieve detailed and high-quality engravings, catering to unique customer preferences.

According to a recent industry report by MarketsandMarkets, the global engraving machine market is projected to reach USD 3.5 billion by 2025, growing at a CAGR of 5.7%. This growth is largely driven by advancements in laser technology and the increasing adoption of automated engraving solutions.

Understanding the specifications of different engraving machines is crucial for businesses in order to select the best fit for their specific needs. In this blog, we will explore the key specifications of engraving machines and provide guidance on how to choose the perfect model that aligns with your operational requirements and enhances productivity.

Understanding the Importance of Precision in Engraving Machines

When it comes to engraving machines, precision is paramount. The quality of the engraving directly depends on the

machine's ability to achieve exact measurements and replicate intricate designs. In industries ranging from

jewelry making to industrial production, even the slightest deviation can lead to defects that are costly

and time-consuming to rectify. Therefore, investing in a machine that emphasizes precision ensures that

every project meets the desired standards, enhancing both aesthetic value and functional performance.

Understanding the specifications that contribute to precision is essential for making an informed choice. Key factors include

the type of engraving technology used—such as laser, rotary, or CNC—and the machine’s resolution and speed.

A higher resolution allows for finer details to be captured, which is particularly important for complex designs.

Meanwhile, speed must be balanced with quality; a machine that engraves quickly may compromise on precision.

By critically evaluating these aspects, users can select an engraving machine that aligns with their

specific needs, ensuring flawless results in every engraving project.

Key Specifications to Consider When Choosing an Engraving Machine

When selecting the perfect engraving machine, understanding key specifications is crucial to ensure optimal performance and quality outcomes. One of the most important factors to consider is the type of engraving technology used—laser, rotary, or chemical engraving—each offering distinct advantages depending on the types of materials and designs you intend to work with.

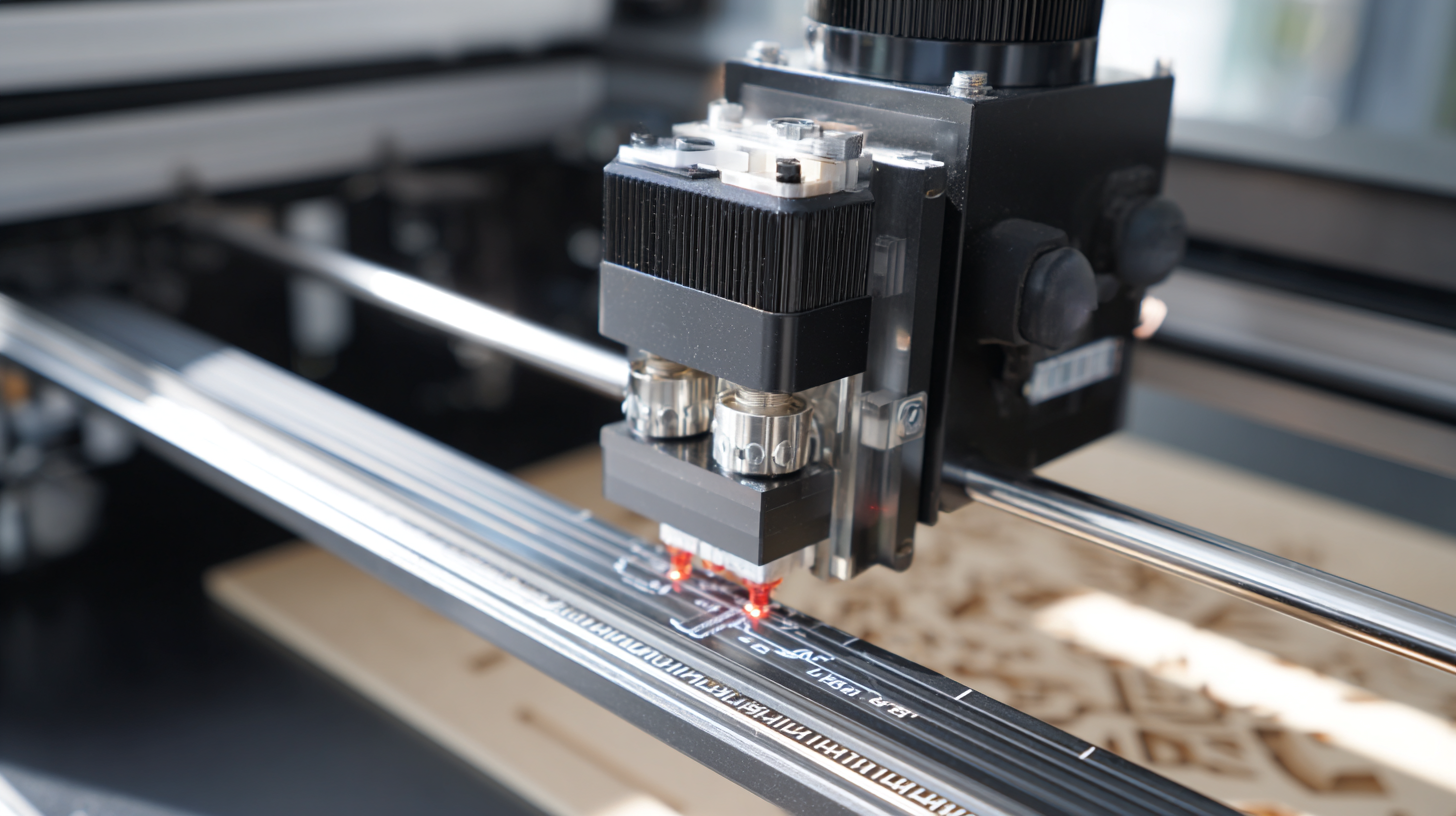

Lasers, for instance, provide high precision and can handle a variety of materials, from wood to glass, making them a versatile choice for both intricate designs and deeper engravings.

Lasers, for instance, provide high precision and can handle a variety of materials, from wood to glass, making them a versatile choice for both intricate designs and deeper engravings.

Another essential specification to evaluate is the machine’s power and speed ratings. The wattage of a laser engraver significantly affects the depth and speed of the engraving process; higher wattage typically allows for faster engraving of tougher materials. Additionally, look for machines with adjustable speed settings, as this flexibility will enable you to customize your engraving projects based on the intricacy of the design and the specific material being used. Exploring these specifications will lead you to an engraving machine that meets your needs and enhances your creative possibilities.

Comparing Different Types of Engraving Machines: Pros and Cons

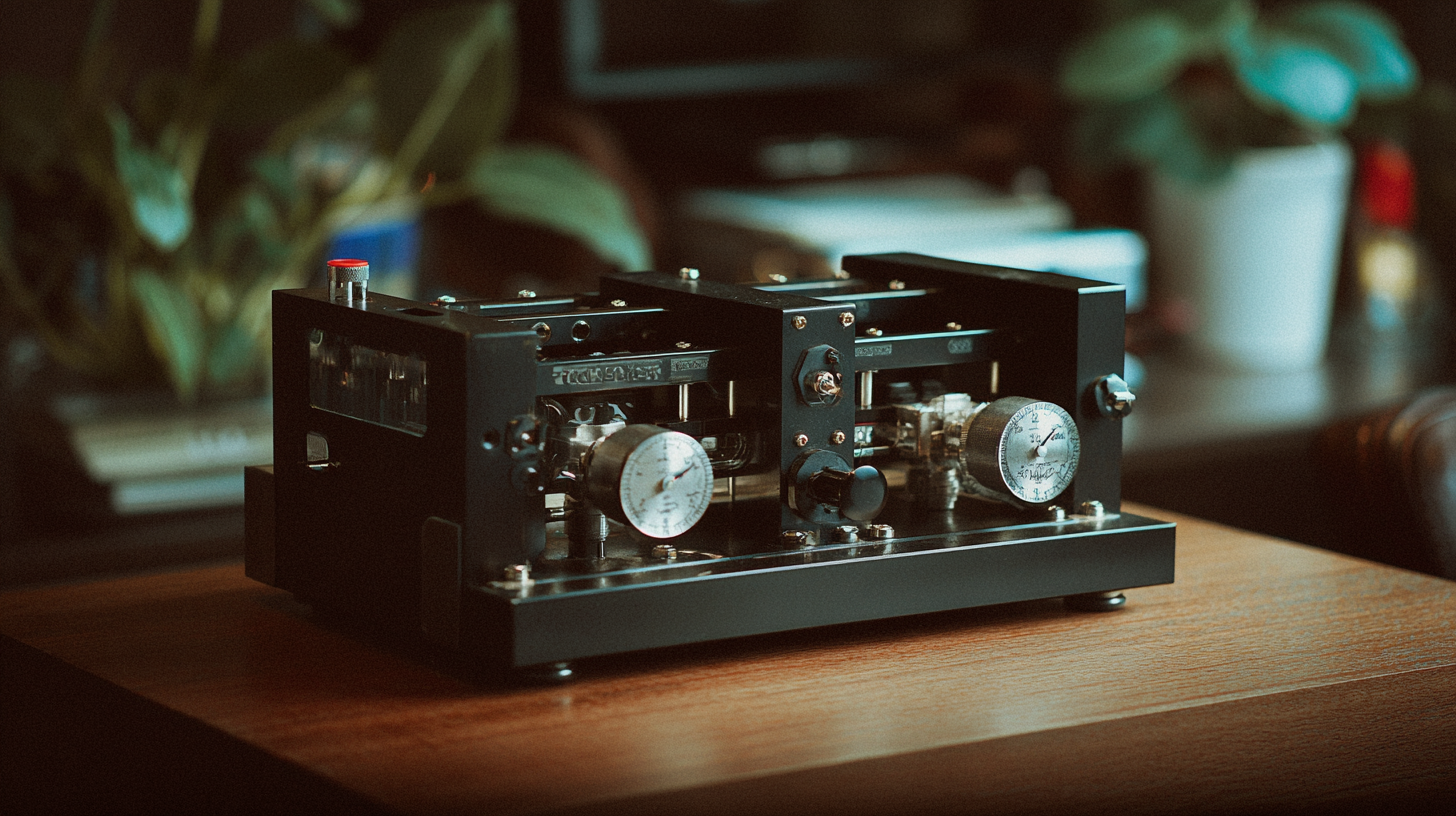

When it comes to selecting the right engraving machine, understanding the various types available is crucial. There are primarily three types: rotary, laser, and CNC engraving machines. Each of these offers distinct advantages and drawbacks that can significantly influence your choice based on your project requirements.

Rotary engraving machines are often celebrated for their versatility and affordability. They excel in engraving on various materials including wood, glass, and metal, making them a popular choice among hobbyists and small businesses. However, they can be slower than other types, which may not suit high-volume operations.

Laser engraving machines provide precision and speed, ideal for intricate designs and detailed work. They can cut through a range of materials with remarkable finesse, but their initial investment can be steep, and they often require more maintenance.

CNC engraving machines bridge the gap between rotary and laser options, offering automated processes and the ability to handle larger projects. While they can be a bit complex to set up and operate, their efficiency in production makes them a powerful tool for professional engravers. However, the learning curve and cost can be significant barriers for beginners. By evaluating these pros and cons, you can make an informed decision that aligns with your engraving needs and budget.

How Chinese Manufacturing is Leading the Engraving Machine Market

The engraving machine market is witnessing a significant transformation, largely driven by advancements in Chinese manufacturing. As one of the biggest players in this field, China has established itself as a hub for precision engineering and production capabilities. With a focus on innovation, Chinese manufacturers are integrating cutting-edge technologies such as fiber laser and CNC engraving, enabling faster and more precise outcomes. These developments not only enhance productivity but also reduce costs, making high-quality engraving machines more accessible to businesses worldwide.

When selecting the perfect engraving machine, consider the following tips to ensure you make an informed choice. Firstly, assess the materials you'll primarily be working with; some machines are better suited for specific materials like wood, metal, or plastic. Secondly, evaluate the machine's engraving speed and precision. A machine that offers adjustable speed settings can cater to varied project requirements, enhancing versatility. Lastly, don’t overlook after-sales support and warranty options, as reliable customer service can significantly impact your purchasing experience and the longevity of your equipment.

By understanding these aspects of Chinese manufacturing in the engraving machine market, you can better navigate your options and find a solution that perfectly fits your engraving needs.

Tips for Selecting the Right Engraving Machine for Your Needs

When it comes to selecting the perfect engraving machine for your specific needs, it’s essential to understand the various specifications and features that can influence your decision. The non-metal laser engraving machine market is projected to reach a value of $359.1 million in 2024 and grow to $575.9 million by 2032, reflecting a steady annual growth rate of 6.1%. This rapid expansion signifies the increasing demand for quality engraving solutions across various industries, including retail, manufacturing, and crafts.

When choosing an engraving machine, consider the material you will be working with, the size of the workspace required, and the level of detail needed in your projects. Look for machines that offer versatility in handling different materials such as wood, plastic, and glass. Additionally, assessing the machine’s power and speed can greatly enhance your productivity. Paying attention to the software compatibility is also crucial, as user-friendly design programs can streamline your workflow. By taking the time to analyze these factors, you can ensure that the engraving machine you choose is the best fit for your creative or business needs.

Unlocking Precision: Best Engraving Machine Specifications and How to Choose the Perfect Fit

| Specification | Details |

|---|---|

| Type | Laser, Rotary, or CNC |

| Working Area | 300mm x 200mm |

| Engraving Speed | 1000 mm/s |

| Max Material Thickness | 15mm |

| Resolution | 0.01 mm |

| Material Compatibility | Wood, Acrylic, Metal, Glass |

| Software Compatibility | Windows, Mac |

| Connectivity | USB, Wi-Fi |

| Price Range | $300 - $2000 |