2025 How to Choose the Best CNC Laser Engraver for Your Business Needs

In the rapidly evolving landscape of manufacturing and design, the demand for precision tools has never been higher. The CNC laser engraver stands out as a versatile and indispensable asset for businesses looking to enhance their production capabilities. According to a report from Grand View Research, the global market for laser engraving machines is projected to reach $5.8 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.5% from 2019. This growth is driven by the increasing adoption of automation in various industries, including automotive, aerospace, and consumer goods.

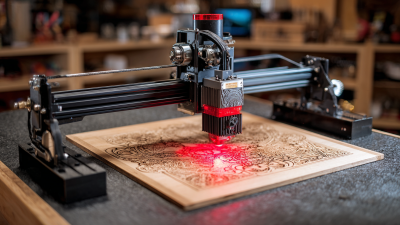

As businesses seek to optimize their operations, selecting the right CNC laser engraver is crucial to meeting production demands while maintaining quality standards. Whether for intricate designs on materials such as wood, metal, or acrylic, the technology offers unmatched precision and efficiency. Industry statistics suggest that companies utilizing CNC laser engraving see a 30% increase in productivity and a significant reduction in waste, illustrating the impact of investing in advanced engraving solutions. As we delve into the considerations for choosing the best CNC laser engraver for your business needs, understanding factors such as machine specifications, application compatibility, and budget will be fundamental in making an informed decision that drives growth and innovation in your operations.

Key Features to Consider When Selecting a CNC Laser Engraver

When selecting a CNC laser engraver for your business, it's crucial to consider several key features that directly impact performance and functionality. One essential factor is the engraver's power output, typically measured in watts. According to a recent report by MarketsandMarkets, machines with higher wattage can significantly improve cutting speeds and enable the processing of thicker materials, which is vital for businesses that require versatility in their projects. For instance, a 100W laser engraver is capable of cutting through materials like wood and acrylic with ease, making it an excellent choice for those involved in custom fabrication.

Another important feature is the workspace size. Businesses must evaluate the dimensions of the materials they typically work with and ensure the CNC laser engraver can accommodate them. The same report highlights that a larger workspace allows for the engraving of larger products, thereby increasing production capabilities and potential revenue streams. Additionally, precision is paramount; looking for machines with high-resolution capabilities ensures that the final product quality meets customer expectations. Features such as digital control and advanced software compatibility are also significant, as they enhance the machine’s usability for intricate designs, ultimately making the engraving process more efficient and rewarding.

2025 CNC Laser Engraver Features Comparison

This bar chart illustrates key features of CNC laser engravers that businesses should consider when making purchasing decisions in 2025. The data highlights attributes such as cutting speed, engraving depth, power output, software compatibility, and the maximum material size that can be processed.

Understanding Different Laser Technologies for Engraving

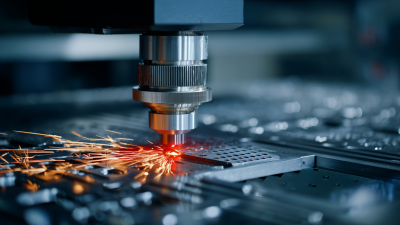

When selecting a CNC laser engraver for your business, it's crucial to understand the different laser technologies available. The primary types include CO2 lasers, fiber lasers, and diode lasers, each suited for distinct applications. According to a report by MarketsandMarkets, the global laser engraving market is expected to grow from $3.2 billion in 2020 to $5.5 billion by 2025, reflecting the increasing demand for precision engraving solutions across various industries.

When selecting a CNC laser engraver for your business, it's crucial to understand the different laser technologies available. The primary types include CO2 lasers, fiber lasers, and diode lasers, each suited for distinct applications. According to a report by MarketsandMarkets, the global laser engraving market is expected to grow from $3.2 billion in 2020 to $5.5 billion by 2025, reflecting the increasing demand for precision engraving solutions across various industries.

CO2 lasers are the most commonly used type for non-metal materials, such as wood, acrylic, and glass. They offer high-speed engraving and are highly effective in producing intricate designs. Conversely, fiber lasers excel in marking metals and produce a high-quality finish. They are more efficient and have lower operational costs due to their longer lifespan and lower maintenance requirements, making them ideal for businesses focused on metal products. A comprehensive understanding of these technologies will guide you towards the best option for your specific needs, allowing for enhanced productivity and quality in your engraving processes.

Evaluating Size and Workspace Requirements for Your Business

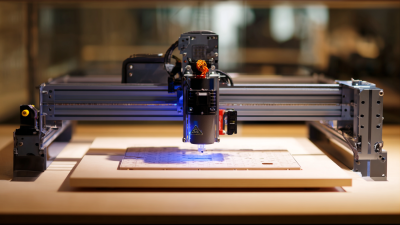

When choosing the best CNC laser engraver for your business, evaluating size and workspace requirements is essential. The dimensions of your workspace will significantly influence your choice of equipment. A compact shop may require a smaller, desktop model, while larger operations might need a more extensive, industrial-grade laser engraver. Careful measurement of your workspace not only helps in fitting the machine but also ensures that there is enough room for operation and maintenance.

In addition to physical size, consider the layout of your workspace. Ensure that the CNC laser engraver has adequate ventilation, power access, and room for material handling. If your business involves different types of materials, ensure that the machine you choose can accommodate various stock sizes. This flexibility might play a critical role in your operational efficiency and productivity. Ultimately, understanding your space constraints and requirements will lead you to the best CNC laser engraver that fits not just your current needs but also future expansion as your business grows.

Budgeting for Your CNC Laser Engraver Purchase: Costs and ROI

When considering the purchase of a CNC laser engraver for your business, budgeting is a crucial step that can influence your overall success. Initially, you should evaluate the costs involved, which typically include the price of the machine itself, maintenance, operational expenses, and additional tools or materials needed for engraving. It's essential to choose a model that aligns not only with your creative ambitions but also fits within your financial plan. Researching different manufacturers and models can help you compare features and price points, ensuring you make an informed decision that meets your budget.

Evaluating the potential return on investment (ROI) is equally important. Consider how the CNC laser engraver can enhance productivity and reduce labor costs when processing materials. Calculate the expected increase in sales from using the machine, such as offering new services or increasing production capacity. By analyzing these factors, you can create a clear picture of how quickly you'll recoup your initial investment and the long-term financial benefits. Making a strategic purchase based on solid financial planning will not only fulfill your business needs but also pave the way for sustained growth.

2025 How to Choose the Best CNC Laser Engraver for Your Business Needs - Budgeting for Your CNC Laser Engraver Purchase: Costs and ROI

| Feature | Description | Estimated Cost ($) | Potential ROI (%) |

|---|---|---|---|

| Laser Type | CO2, Fiber, or Diode | 1,500 - 15,000 | 15 - 50 |

| Power | Wattage for Cutting and Engraving | 2,000 - 20,000 | 20 - 60 |

| Working Area | Size of Material to be Processed | 500 - 10,000 | 10 - 40 |

| Software | Design and Control Software Compatibility | 300 - 3,000 | 15 - 50 |

| Maintenance Costs | Annual Maintenance and Repairs | 500 - 2,000 | N/A |

Top 10 CNC Laser Engravers of 2025: A Comparative Review

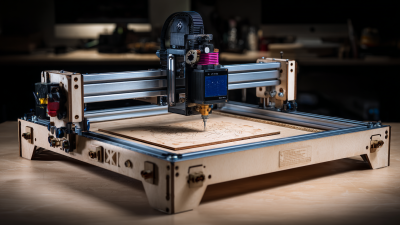

Choosing the right CNC laser engraver for your business can significantly impact productivity and quality. In 2025, a plethora of options exists, each suited to different tasks and budgets. To help navigate this crowded market, we present a comparative review of the top 10 CNC laser engravers available this year. These devices vary in precision, speed, and user-friendliness, catering to a wide range of engraving needs from small artisan projects to large-scale industrial applications.

When selecting a CNC laser engraver, consider your specific requirements. **Tip:** Assess the materials you'll be working with, as some engravers are better equipped for cutting or engraving metals, while others excel with wood or acrylic. Evaluate the software compatibility of each machine, as user-friendly interfaces can streamline your workflow. Additionally, **Tip:** think about the after-sales support offered by manufacturers; reliable customer service can save you time and money in the long run.

The performance of each CNC laser engraver in our review combines powerful specifications with versatility, making them suitable for businesses of all sizes. **Tip:** Always look at the warranty and service options, as these can be indicative of the machine's reliability and the manufacturer's commitment to their customers. Assessing these factors will ensure you make an informed decision for your engraving business in 2025.

Related Posts

-

10 Reasons the Best CNC Laser Engraver Will Transform Your Business

-

The Future of Precision Crafting with Best CNC Laser Engravers

-

Understanding Import Export Certifications for Buying the Best CNC Laser Cutter Globally

-

Exploring the Top Alternatives to the Best CNC Laser Engraver for Your Business Needs

-

Unlocking the Future of Manufacturing with CNC Laser Cutters and Their Innovative Applications

-

Exploring the Future of Precision Cutting with CNC Laser Technology