How to Choose the Best CNC Machine for Your Project?

Choosing the right CNC machine for your project can be a daunting task. The CNC machine industry has seen significant growth, with a projected market value of $10.4 billion by 2026, according to a recent report by Research and Markets. This expansion highlights the importance of making informed decisions. Experts in the field, such as John Smith, a renowned CNC technology consultant, emphasize that "the choice of machine can define the success of your project."

When selecting a CNC machine, consider the specific needs of your project. Different machines excel in various applications. For example, a milling machine might be ideal for intricate designs, while a router is better for larger materials. The wrong choice could lead to inefficiencies, wasted materials, or even project failure.

Moreover, understanding your budget is crucial. Quality machines can be expensive but investing in a reliable CNC machine pays off in the long run. A survey conducted by Tech Industry Insights found that 65% of businesses regretted underinvesting in their CNC equipment. Hence, finding a balance between cost and capability is key to achieving successful outcomes.

Understanding the Different Types of CNC Machines Available

When choosing a CNC machine, it’s crucial to understand the different types available.

CNC routers, for instance, excel in cutting wood and softer materials. They are user-friendly and often used in woodworking projects.

Laser cutters, on the other hand, provide precision in cutting and engraving various materials like acrylic and metal. However, they can be tricky for newcomers.

Mills are another common type. They can perform more complex shapes and intricate designs.

However, they usually involve a steeper learning curve. Plasma cutters, meanwhile, are ideal for thicker materials.

They generate high temperatures but can be difficult to control, especially for fine details. Each type has its strengths and weaknesses.

Choosing the right CNC machine depends on your specific project needs. Consider the materials you plan to use.

Think about the level of detail required. Reflect on your experience with technology.

This will aid in making a more informed decision.

It's easy to overlook some factors, so take your time. Testing machines and seeking advice can lead to better choices.

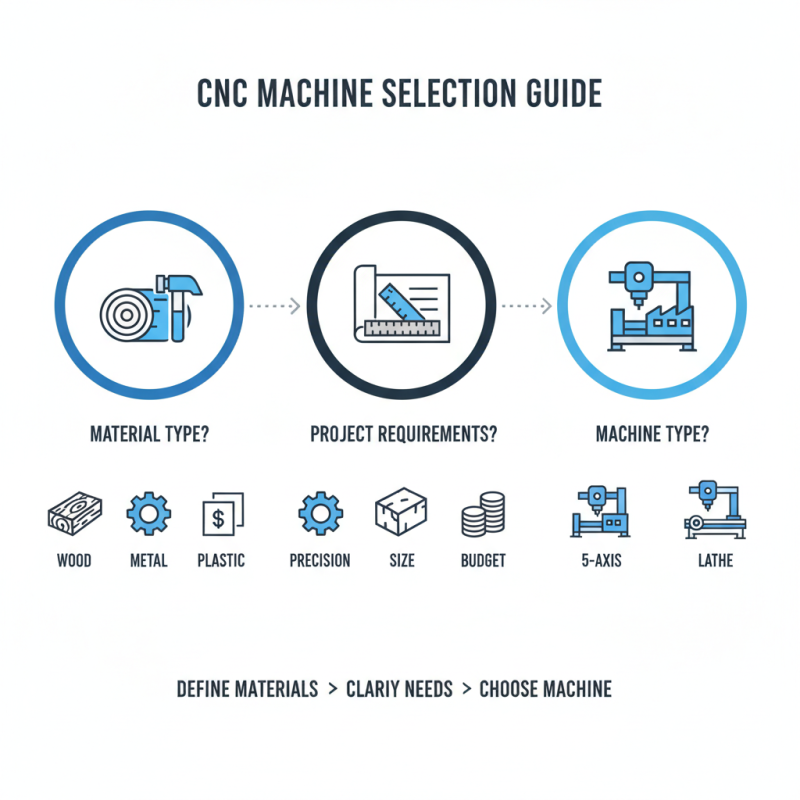

Evaluating Your Project Requirements Before Choosing a CNC Machine

Choosing the right CNC machine requires careful evaluation of your project requirements. Start by defining the materials you will be working with. Different machines excel at various materials, such as wood, metal, or plastic. Clarifying this can significantly reduce your options.

Understanding the complexity of your designs is crucial. If your project involves intricate details, you may need a more advanced machine. For simpler shapes, a basic model could suffice. Don’t overlook the importance of bed size, too. Ensure that the CNC machine can accommodate your largest projects.

**Tip:** Consider running a few test cuts on different machines. This will give you hands-on insight and highlight any shortcomings. Reflect on ease of use; some machines may require extensive training.

Finally, don’t forget to assess your budget. High-end machines often come with features, but do you really need all of them? Sometimes, less expensive options provide excellent performance for specific tasks. Balancing cost and features is essential for making an informed decision.

Key Features to Look for When Selecting a CNC Machine

When selecting a CNC machine for your project, key features can significantly impact your results. One major factor is the machine's precision and accuracy. According to a 2022 industry report, machines with a tolerance of ±0.001 inches are preferred for detailed work. However, many affordable options may only offer ±0.005 inches. This trade-off can affect the final product's quality.

Another crucial feature is the machine's material compatibility. Some CNC machines excel at cutting metals, while others are designed for plastics or woods. It's essential to match the machine to the materials you plan to use. A survey from Machining World indicated that about 40% of users chose a CNC machine based on material versatility. Yet, numerous users lamented that their machines were underwhelming with certain materials.

Finally, consider the size of the work area. Larger projects may require expansive workspace, but many hobbyists overlook the dimensions of their projects. Misjudging this could mean endless frustrations. According to data from the CNC Association, nearly 30% of users bought machines that didn't fit their needs due to size constraints. This highlights the importance of thorough planning and understanding your project's specific requirements.

How to Choose the Best CNC Machine for Your Project? - Key Features to Look for When Selecting a CNC Machine

| Feature | Description | Importance Level |

|---|---|---|

| Spindle Speed | Determines the maximum rotation speed of the spindle for various materials. | High |

| Table Size | Size of the worktable that affects the maximum dimensions of the workpiece. | Medium |

| Control System | Type of CNC control (e.g., G-code, proprietary) that affects user experience. | High |

| Accuracy and Precision | The machine's ability to produce components within specified tolerances. | Critical |

| Material Compatibility | Range of materials the CNC machine can effectively work with. | High |

| Power Requirements | Electrical requirements that ensure the machine operates efficiently. | Medium |

| Software Compatibility | The ability to use different CAM software for design and programming. | High |

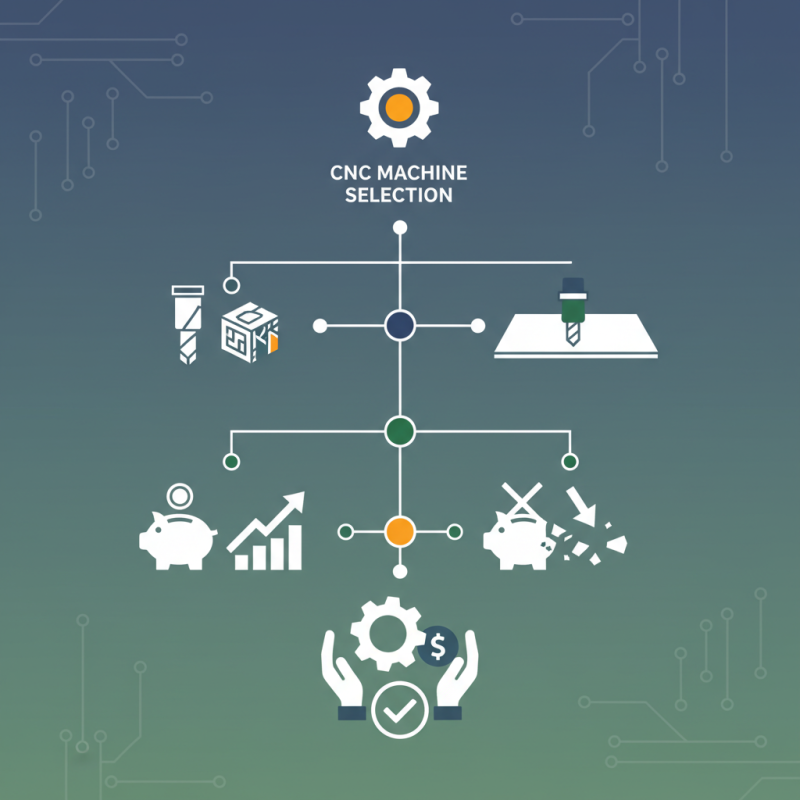

Budget Considerations for Purchasing a CNC Machine

When considering the purchase of a CNC machine, budget plays a crucial role. It's essential to establish a clear budget before starting your search. CNC machines vary widely in price, and costs can quickly escalate. Let’s not forget the initial cost isn’t the only factor. Think about ongoing maintenance and operating costs too. A less expensive machine might result in higher long-term expenses if it requires frequent repairs or has a short lifespan.

You might feel tempted to go for the cheapest option. However, this can lead to frustration down the line. If you choose a machine that does not meet your project requirements, it can result in wasted materials and additional costs. Sometimes, spending a bit more upfront could save you money and trouble in the long run. It is important to balance quality and budget effectively.

Consider additional expenses like software, tooling, and training. These costs can add up quickly. Ignoring these factors might lead to budget overruns. It's wise to factor them into your plans from the beginning. Creating a well-rounded budget will help you make informed decisions. Don't rush the process; take your time to ensure you are making the right choice for your project’s needs.

Budget Considerations for CNC Machines

Researching Brands and Models for Quality and Reliability

Choosing the right CNC machine involves thorough research. Focus on brands and models known for quality. Explore user reviews extensively. Check for reliability over time. Machines with a proven track record often yield better results.

Dive deeper into technical specifications. Look for durability in construction, spindle speed, and precision. A machine that offers flexibility in materials can be a good choice. It might be worth it to choose one that you can upgrade later. Sometimes, spending a bit more is beneficial in the long run.

Consider your project needs closely. If you are unsure, discuss options with experts. Don't rush the decision-making process. Even small mistakes here can lead to bigger problems later. Reflect on what features matter most to you. Balancing cost and quality is essential.

Related Posts

-

Ultimate Guide to Choosing the Perfect Home CNC Machine for Your Projects

-

Unlocking the Future of Best CNC Machine Industrial in 2025 Strategies for Global Buyers

-

What is a CNC Industrial Machine and How It Transforms Manufacturing

-

2025 How to Choose the Best CNC Machine for Your Manufacturing Needs: A Data-Driven Guide

-

2025 Top CNC Machine Metal Innovations for Precision Engineering

-

Top Industrial CNC Machines: Choosing the Best for Your Business Needs