What Kind of CNC Machines Are Right for Your Manufacturing Needs?

In the rapidly evolving landscape of manufacturing, choosing the right CNC machine is paramount for businesses aiming to enhance productivity and precision. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach USD 117.72 billion by 2026, growing at a CAGR of 6.9% from 2021. As manufacturers increasingly realize the importance of automation and efficiency, selecting a CNC machine that aligns with their specific manufacturing needs can be a game-changer. Different types of CNC machines—ranging from milling and turning to laser cutting—offer unique capabilities suitable for diverse applications. This blog will explore the various kinds of CNC machines available and provide insights on how to determine which one is the best fit for your business, ensuring that you stay competitive in a rapidly advancing market.

Understanding the Basics of CNC Machines in Manufacturing

When it comes to understanding CNC machines in manufacturing, it’s crucial to grasp how they operate and the role they play in modern production processes. CNC (Computer Numerical Control) machines are designed to automate precision tasks, allowing for greater efficiency and scalability. By using advanced software and hardware, these machines can produce complex parts with incredible accuracy. A foundational aspect of effectively utilizing CNC technology is knowing the significance of post processors, which translate CAD/CAM software instructions into machine-readable code, ensuring optimal operation of the equipment.

Tips: To maximize the capabilities of your CNC machine, consider investing time in training for your operators on programming and toolpath generation. Additionally, incorporating process planning strategies for hybrid manufacturing can enhance workflow efficiency and reduce downtime. Monitoring the energy consumption of your machines is also essential; utilizing energy efficiency checklists can guide you in minimizing operating costs while maintaining optimal performance.

As the industry evolves, leveraging technologies like digital twins can provide real-time insights into production processes, boosting efficiency and enabling proactive maintenance. With the integration of AI in CNC machining, manufacturers can expect innovations that will further streamline operations and enhance precision, diminishing traditional manufacturing challenges.

Types of CNC Machines and Their Unique Applications

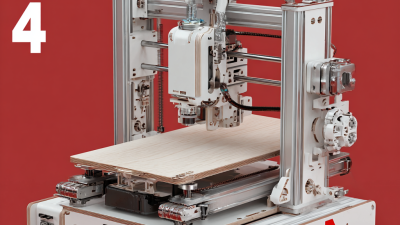

When it comes to choosing the right CNC machine for your manufacturing needs, it's essential to understand the various types available and their unique applications. CNC machines range from traditional milling machines to modern laser and plasma cutting systems. Each type of machine is engineered for specific tasks, such as CNC milling for complex parts, CNC turning for precise cylindrical shapes, and CNC laser cutting for intricate designs. As the global CNC machine market is projected to grow significantly, from $101.22 billion in 2025 to $195.59 billion by 2032, understanding these applications becomes even more vital for manufacturers looking to invest wisely.

New technologies like touch probing systems and augmented reality are enhancing the capabilities of CNC machines, providing manufacturers with tools for automatic data collection and improved quality control. Additionally, CNC plasma cutting machines are gaining popularity, expected to grow from $707.5 million in 2025 to $1.16 billion by 2035, showcasing the increasing demand for specialized cutting technologies. As these machines continue to evolve, manufacturers must keep pace with the advancements to ensure they select the right CNC machines that align with their production goals and enhance efficiency in their operations.

Types of CNC Machines and Their Applications

Factors to Consider When Choosing CNC Machines for Your Shop

When choosing CNC machines for your manufacturing needs, several key factors come into play. First, the type of materials you will be machining is crucial. For instance, according to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, largely driven by a surge in demand across various materials, including metals and plastics. Therefore, selecting a machine that can handle the specific material properties—such as hardness, thermal conductivity, and weight—is essential for optimizing production efficiency.

When choosing CNC machines for your manufacturing needs, several key factors come into play. First, the type of materials you will be machining is crucial. For instance, according to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, largely driven by a surge in demand across various materials, including metals and plastics. Therefore, selecting a machine that can handle the specific material properties—such as hardness, thermal conductivity, and weight—is essential for optimizing production efficiency.

Another critical factor to consider is the precision required for your projects. According to a study from Technavio, precision CNC machines, which maintain an accuracy of ±0.01 mm or better, are becoming increasingly sought after in industries such as aerospace and medical equipment manufacturing. This demand underscores the importance of investing in machines that not only meet current tolerances but are also scalable for future needs. Taking these aspects into account will help ensure that your shop is equipped with the right CNC machines to meet both present and future manufacturing challenges.

The Benefits of Investing in the Right CNC Technology

Investing in the right CNC technology can significantly enhance your manufacturing capabilities. One of the primary benefits is increased precision and consistency in production. CNC machines eliminate the variability associated with manual machining. This level of accuracy not only improves the quality of your products but also reduces waste and the costs associated with errors. As a result, businesses can meet tighter tolerances and complex designs more efficiently, leading to higher customer satisfaction and repeat orders.

Another advantage of investing in advanced CNC technology is the potential for increased production speed. Modern CNC machines are equipped with high-speed capabilities and automation features, which allow for faster cycle times and reduced downtime. This means that manufacturers can take on more projects and scale their operations without compromising quality. Furthermore, the integration of software solutions for design and operation streamlines workflows, enabling companies to respond quickly to market demands and stay competitive in a fast-paced environment. By choosing the right CNC machines tailored to specific manufacturing needs, businesses can unlock significant operational benefits and drive growth.

What Kind of CNC Machines Are Right for Your Manufacturing Needs? - The Benefits of Investing in the Right CNC Technology

| CNC Machine Type | Applications | Materials | Benefits |

|---|---|---|---|

| CNC Milling Machine | Manufacturing parts, prototyping | Metals, plastics | Precision machining, flexibility |

| CNC Lathe | Turning operations, creating cylindrical parts | Metals, wood | High accuracy, complex shapes |

| CNC Router | Cutting wood, plastic, and composites | Wood, MDF, plastics | Speed, ease of use |

| CNC Plasma Cutter | Metal cutting | Steel, aluminum | High speed, cost-effective |

| CNC Wire EDM | Intricate cutting | Hard metals | Extreme precision, minimal material loss |

Comparing Cost vs. Performance: Finding Your CNC Sweet Spot

When investing in CNC machines for your manufacturing needs, balancing cost and performance is paramount. The first step is to define the specific requirements of your projects, which include material types, desired tolerances, and production volume. Understanding your production goals will help you identify machine features that are essential for your operations. For example, a high-speed milling machine may offer superior accuracy, but if your production does not require such precision, opting for a more affordable alternative could lead to significant savings without compromising quality.

Additionally, it's crucial to evaluate the long-term costs associated with each machine. While a lower upfront cost can be attractive, factors such as maintenance, energy efficiency, and software compatibility can significantly affect overall performance and expense. Investing in a machine with higher durability and advanced technology may prove more economical in the long run.

By comparing the performance capabilities relative to their cost, manufacturers can find their "CNC sweet spot," ensuring they get the best return on investment while meeting their specific operational needs.

Related Posts

-

Unlocking the Future of Best CNC Machine Industrial in 2025 Strategies for Global Buyers

-

Unveiling the Technical Specifications of the Best CNC Machine for Precision Engineering

-

Exploring the Future of Best CNC Engraving Machines in 2025 and How to Choose the Right One

-

7 Amazing Features of the Best 3D CNC Machine You Need to Know

-

China's Intelligent Manufacturing Revolutionizes the Global Market for Best CNC Router Machines

-

Top Strategies for Choosing the Best CNC Router for Your Business Needs