What is a CNC Industrial Machine and How Does it Work?

A CNC industrial machine is a remarkable tool in modern manufacturing. It uses computer numerical control to automate tasks. This technology allows for precise cutting, milling, and engraving of materials like metal and plastic. With a CNC industrial machine, manufacturers can achieve high levels of accuracy and repeatability.

The working principle is relatively straightforward. A design is created on a computer, then fed to the CNC machine. The machine interprets this data and performs the task with precision. However, this process requires careful calibration and maintenance. Small errors can lead to defects in the final product, which can be costly.

Despite their efficiency, the machines also present challenges. Operators need training to ensure they can handle the software and equipment properly. Without adequate knowledge, errors may arise. Therefore, continuous learning is crucial in this evolving field of manufacturing. Understanding the workings and potential pitfalls of a CNC industrial machine can drive improvements and innovation.

What is a CNC Industrial Machine?

CNC stands for Computer Numerical Control. A CNC industrial machine is a precise tool used to create various components. It operates using computer programs that control the movements of the machine’s tools. This automation allows for high levels of accuracy in cutting, shaping, and milling materials.

CNC machines can work with metals, plastics, and wood. They cut materials based on detailed designs. The operator creates a code, usually in G-code, that the machine understands. Once programmed, the machine can perform repetitive tasks with minimal errors. However, the initial setup may require adjustments. It's crucial to ensure the correct tools and setups are used.

Tips: Make sure to regularly maintain the machine. Regular checks can prevent costly mistakes. Additionally, always double-check your program before starting the machine. Small errors in coding can lead to significant issues. It's essential to remain vigilant during operation, as even minor distractions can cause problems. Remember, safety always comes first when working with heavy machinery.

Core Components of CNC Machines

CNC machines are fascinating tools used in various industries. Their core components play a crucial role in their operation. At the heart of a CNC machine is the controller. This device interprets the design data and converts it into machine movements. It often utilizes G-code to dictate the machine's actions.

Motors are another essential component. They drive the movement of the machine along different axes. Stepper motors and servo motors are commonly used for precision movement. These motors need to be properly calibrated. Incorrect calibration can lead to poor accuracy in the final product.

Moreover, the spindle is vital for machining tasks. It rotates cutting tools at high speeds. This rotation allows for precise cutting, drilling, or milling. However, the spindle must be maintained regularly. Neglecting its upkeep can lead to reduced performance and even machine failure. Each component interacts with others, contributing to the overall effectiveness of CNC machines. Understanding these details can help users avoid costly mistakes in their operations.

What is a CNC Industrial Machine and How Does it Work? - Core Components of CNC Machines

| Component | Description | Function |

|---|---|---|

| CNC Controller | The brain of the CNC machine, it interprets the G-code commands. | Controls machine movements and operations. |

| Servo Motors | Electric motors that provide precise control of the machine axis. | Facilitates accurate movement and positioning. |

| Linear Guides | Mechanical elements that allow linear movement along a track. | Ensures smooth and precise motion in linear operations. |

| Spindle | Rotating shaft that holds cutting tools and performs machining. | Executes cutting, drilling, or milling processes. |

| Tool Holder | Holds the cutting tool in place during machining. | Ensures tool stability and precision during operations. |

| Coolant System | System for cooling the tool and workpiece during cutting. | Reduces heat and prolongs tool life. |

How CNC Machines Operate: An Overview

CNC machines, or Computer Numerical Control machines, revolutionize the manufacturing industry. They automate processes like cutting, milling, and engraving. These machines work by interpreting digital designs and converting them into precise physical movements.

The operation of CNC machines begins with a computer program. This program contains the specific instructions for the machine's movements. The machine uses motors to manipulate tools along various axes. These motors provide high accuracy and speed. The materials are often placed on a table, and the machine performs tasks with minimal human intervention.

Not every CNC machine operates flawlessly. Calibration issues can arise, leading to inaccuracies. Sometimes, operators may overlook small details in the programming. These oversights can produce parts that do not meet specifications. Regular inspections and maintenance are crucial. They ensure that the machines function properly and produce quality items.

Applications of CNC Machines in Various Industries

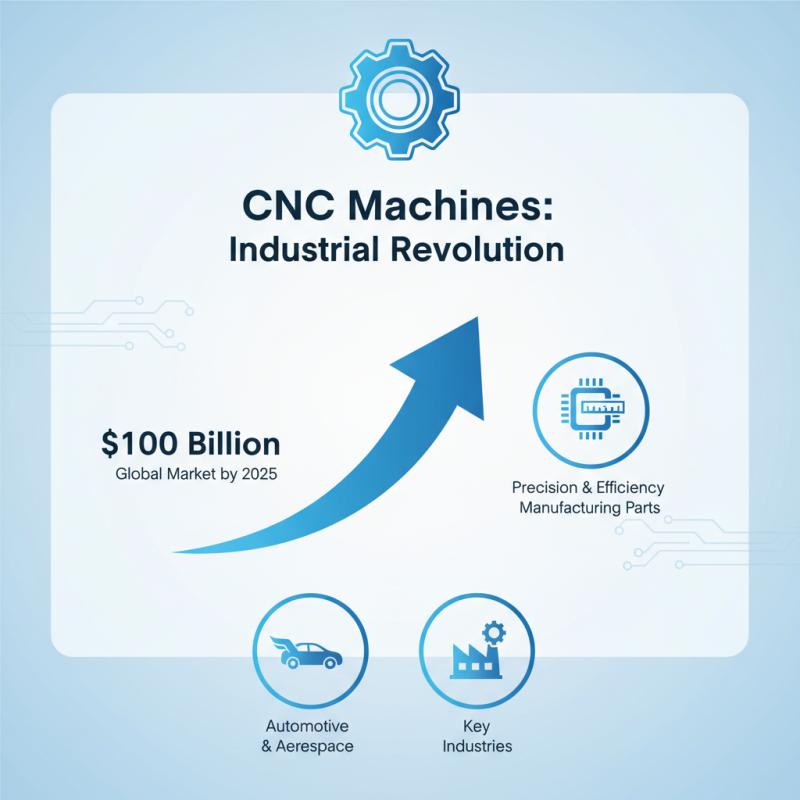

CNC machines are revolutionizing many industries today. In manufacturing, they are key in producing parts with precision and efficiency. Reports indicate that the global CNC machine market will reach $100 billion by 2025. Industries like automotive and aerospace heavily rely on CNC technology for their component production.

In the automotive sector, CNC machines create intricate parts for engines and chassis. This enhances performance and safety. Furthermore, the aerospace industry uses CNC for crafting components that meet strict regulations. However, this reliance on technology poses challenges. There’s a need for skilled operators who understand the technology to avoid costly errors.

Additionally, CNC machines are employed in woodworking and metalworking. They enable artisans to create customized designs quickly. Yet, many small businesses struggle to keep up with the technology's rapid advancement. Investing in CNC training can be expensive and time-consuming. Balancing technology with craftsmanship remains a critical reflection for these industries.

Benefits of Using CNC Technology in Manufacturing Processes

CNC (Computer Numerical Control) technology has revolutionized manufacturing. It enhances precision and efficiency. According to a report by the International Federation of Robotics, the use of CNC technology can increase productivity by up to 30%. This improvement allows manufacturers to produce high-quality parts with less waste.

One major benefit of CNC technology is its consistency. Unlike manual machining, CNC machines follow programmed instructions. This ensures each piece is made to the same specifications. Additionally, some studies reveal that CNC machines can operate continuously for longer periods. While they still require maintenance, this efficiency maximizes production capabilities.

However, the initial setup for CNC machines can be costly. Some small businesses might struggle with this investment. Also, CNC technology demands skilled operators who can manage complex programming. Finding talent remains a challenge. Manufacturers must balance the benefits with the costs and training needs. This reflection is crucial for companies considering CNC integration.

Benefits of Using CNC Technology in Manufacturing Processes

Related Posts

-

How to Choose the Best CNC Machine for Your Project?

-

How to Optimize Your CNC Router Machine for Maximum Efficiency and Precision

-

Top Industrial CNC Machines: Choosing the Best for Your Business Needs

-

Top 10 CNC Industrial Machines for Enhanced Precision and Productivity

-

Unlocking Precision: How CNC Industrial Machines Revolutionize Manufacturing Efficiency

-

Ultimate Guide to Choosing the Perfect Home CNC Machine for Your Projects