What is a CNC Industrial Machine and How It Transforms Manufacturing

The advent of CNC industrial machines has revolutionized the manufacturing landscape, offering unprecedented precision and efficiency. According to a recent report by MarketsandMarkets, the CNC machine market is projected to reach USD 117.75 billion by 2026, growing at a CAGR of 6.5% from 2021. This growth is fueled by the increasing demand for automation in various industries, from aerospace to automotive. CNC industrial machines enable manufacturers to produce complex components with minimal human intervention, reducing the likelihood of errors and enhancing productivity. As businesses strive for higher quality and faster turnaround times, understanding the functionality and potential of CNC technology becomes essential for staying competitive in today’s dynamic market. This blog will explore the core concepts of CNC industrial machines and their transformative impact on modern manufacturing processes.

Understanding CNC Machines: The Backbone of Modern Manufacturing

CNC machines, or computer numerical control machines, have become the backbone of modern manufacturing due to their precision, efficiency, and versatility. They enable automated fabrication of complex parts, crucial for industries ranging from aerospace to automotive. With advancements in technology, these machines are undergoing rapid innovation, allowing manufacturers to improve productivity while reducing waste. For example, China's growing capabilities in advanced manufacturing are reshaping global competition, particularly in key sectors like automotive and chemicals.

**Tip:** When working with CNC machines, ensure to maintain regular maintenance schedules. This not only prolongs the lifespan of the equipment but also enhances operational reliability, preventing costly downtimes.

Moreover, recent developments in metal additive manufacturing highlight the integration of CNC systems with cutting-edge technologies. This combination facilitates the production of intricate components that traditional methods might struggle to create. As industries embrace these innovations, the demand for skilled workers trained in CNC technology continues to rise. Community colleges and vocational programs are increasingly stepping up to fill this gap, providing essential training that can transform careers.

**Tip:** Explore training programs in your area that focus on CNC machining. Participating in hands-on workshops can significantly enhance your skills and employability in the evolving manufacturing landscape.

Key Components of CNC Industrial Machines and Their Functions

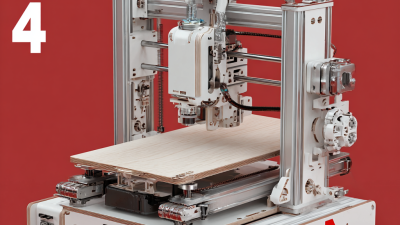

CNC industrial machines play a critical role in modern manufacturing, transforming traditional processes through precision and automation. Understanding the key components of these machines is essential for grasping their profound impact on various industries.

The main elements include the computer control unit, which processes inputs and sends instructions, the drive motors that provide movement, and the tool holders that secure and manage the cutting tools. These components work in harmony to produce intricate parts used in sectors ranging from aerospace to medical devices, ensuring unmatched accuracy and efficiency.

As various industries embrace CNC technology, market growth is anticipated, particularly in precision parts manufacturing. Recent reports highlight that the CNC milling machine market is projected to rise significantly, indicating a shift towards increased automation and digitalization in production. This trend aligns with the broader movement towards Industry 4.0, where intelligent manufacturing systems are essential for optimizing performance and reducing costs. To support this revolution, manufacturers must prioritize cybersecurity, addressing vulnerabilities in IoT devices and automation software. A robust security framework is necessary to protect the integrity of manufacturing systems and maintain operational efficiency in this rapidly evolving landscape.

How CNC Technology Streamlines Production Processes and Reduces Waste

CNC technology has revolutionized the manufacturing landscape by streamlining production processes and significantly reducing waste. According to a report by the Manufacturing Technology Association, implementing CNC machinery can increase production efficiency by up to 30% and decrease scrap rates by 15% or more. This efficiency stems from the precision and automation that CNC machines provide, allowing manufacturers to create highly complex parts with minimal human intervention. Consequently, businesses can operate with leaner inventories, reduce lead times, and improve overall product quality.

**Tip:** When investing in CNC technology, consider starting with small pilot projects to assess the impact on your production workflow. This will help you gauge the efficiency improvements and inform larger scale rollouts.

Furthermore, CNC machines contribute to sustainability in manufacturing by minimizing material waste. Research from the National Institute of Standards and Technology indicates that optimizing CNC machining processes can lead to a 20% reduction in waste materials. This not only lowers costs but also aligns operations with more environmentally friendly practices—an increasingly important aspect for modern consumers and industries alike.

**Tip:** Regular maintenance and software updates on CNC machines can further enhance their efficiency, ensuring that your operations remain at the forefront of technological advancements in manufacturing.

The Advantages of CNC Machining Over Traditional Manufacturing Methods

CNC machining has revolutionized the manufacturing industry by offering a level of precision and efficiency that traditional methods struggle to match. Unlike conventional machining processes, which often require multiple setups and manual interventions, CNC machines automate the production process, minimizing human error and providing consistent results. This automation leads to shorter lead times and improved productivity, enabling manufacturers to meet the demands of a fast-paced market.

One of the most significant advantages of CNC machining is its ability to create complex geometries that would be challenging or impossible to achieve with manual techniques. Whether it’s intricate parts for aerospace applications or customized components for medical devices, CNC technology excels in producing high-quality parts on a large scale. Additionally, the cost-effectiveness of CNC machining becomes apparent in high-volume production runs, where the reduction in labor costs and material waste translates into substantial savings for manufacturers. As industries continue to seek innovative solutions, CNC machining stands out as a superior alternative to traditional manufacturing methods.

Future Trends: The Evolution of CNC Machines in the Manufacturing Sector

The evolution of CNC (Computer Numerical Control) machines is reshaping the manufacturing landscape by integrating advanced technologies and automation. As industries seek enhanced productivity and precision, CNC machines are increasingly being adopted across various sectors. The global woodworking machinery market size is projected to rise significantly, reflecting the growing trend in automation and smart manufacturing. This shift not only promises improved efficiency but also supports environmentally friendly practices by minimizing waste and optimizing resource use.

Looking ahead, the integration of artificial intelligence and the Industrial Internet of Things (IIoT) into CNC machine operations is expected to drive further transformation. The synergy of these technologies enables real-time data analysis and machine learning capabilities, allowing manufacturers to refine their processes continually. The upcoming years are crucial for the robotics industry, as national policies and initiatives aim to accelerate domestic developments, fostering a golden age for industrial robots. As manufacturers adapt to these trends, the future of CNC machines is poised to bring about unprecedented changes in production techniques and methodologies, setting new standards for the manufacturing sector worldwide.

What is a CNC Industrial Machine and How It Transforms Manufacturing - Future Trends: The Evolution of CNC Machines in the Manufacturing Sector

| Parameter | Description | Impact on Manufacturing |

|---|---|---|

| Precision | CNC machines provide high accuracy in manufacturing parts. | Improves quality control and reduces waste. |

| Automation | Automated operation reduces the need for manual labor. | Increases productivity and consistency in production. |

| Flexibility | Ability to produce a variety of parts with minimal setup changes. | Enables rapid response to market demands. |

| Cost Efficiency | Reduction in material waste and improved manufacturing times. | Lower operational costs and increased profit margins. |

| Technology Integration | Integration with IoT and AI for advanced analytics. | Enhances decision-making and predictive maintenance. |

Related Posts

-

Unveiling the Technical Specifications of the Best CNC Machine for Precision Engineering

-

Unlocking the Future of Best CNC Machine Industrial in 2025 Strategies for Global Buyers

-

What Kind of CNC Machines Are Right for Your Manufacturing Needs?

-

7 Amazing Features of the Best 3D CNC Machine You Need to Know

-

Top Strategies for Choosing the Best CNC Router for Your Business Needs

-

Global Leaders in Manufacturing Unveiling the Best Industrial CNC Solutions