Top 10 CNC Industrial Machines for Enhanced Precision and Productivity

In the rapidly evolving landscape of manufacturing, the role of CNC industrial machines has become increasingly pivotal, redefining the standards of precision and productivity. According to Dr. Emily Carter, an expert in automated manufacturing technologies, "The integration of advanced CNC industrial machines is not just an enhancement; it's a necessity for staying competitive in today's market." Her insights underscore the importance of selecting the right equipment to meet the demands of modern production.

This article explores the top 10 CNC industrial machines that stand out for their capability to enhance operational efficiency and precision. With cutting-edge technology at their core, these machines offer innovative solutions for various industrial applications, from intricate component manufacturing to large-scale production runs. By adopting these advanced tools, companies can not only improve their output quality but also significantly reduce operational costs, positioning themselves as leaders in the industry.

As we delve into the specifics of each machine, it’s essential to consider the implications of technological advancements in CNC industrial machines—how they transform workflows, optimize processes, and ultimately drive greater success in manufacturing endeavors. Join us as we unpack the features and benefits of these top contenders and their potential impact on the future of production.

Overview of CNC Industrial Machines and Their Importance

CNC (Computer Numerical Control) industrial machines revolutionize the manufacturing landscape by enhancing precision and productivity. They allow for automated control of machining tools through computer programming, enabling manufacturers to produce intricate designs with minimal human intervention. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, reflecting the increasing demand for high-precision machining processes across various industries. This technology not only improves accuracy but also reduces waste, making it a critical component for companies striving for operational efficiency.

When implementing CNC technology, it is crucial to consider the compatibility of software and machinery. Investing in advanced CNC systems can lead to significant productivity gains, as the automation streamlines workflows. A study by Deloitte highlights that organizations utilizing CNC machines can see productivity improvements of up to 50%. This efficiency translates to faster production times and reduced labor costs, allowing manufacturers to remain competitive in a fast-evolving market.

Tips for maximizing the benefits of CNC machines include regular maintenance and investment in employee training. Regular maintenance ensures machines operate at peak performance, minimizing downtime and costly repairs. Moreover, training employees on the latest CNC technologies can enhance their skills and adaptability, fostering a workforce that is equipped to handle the complexity of modern machinery. Embracing continuous improvement in these areas can yield substantial returns on investment in CNC technology.

Key Features to Consider in CNC Machinery Selection

When selecting CNC machinery for industrial applications, several key features should be taken into consideration to enhance precision and productivity. One of the primary factors is the machine's rigidity and stability. A robust frame reduces vibration and enhances accuracy during operation, which is crucial for achieving tight tolerances. Additionally, the quality of the spindle plays a significant role in determining the overall performance; a high-speed spindle not only increases production rates but also allows for better surface finishes.

Another important aspect is the software capabilities of the CNC machine. Advanced programming interfaces and compatibility with various CAD/CAM software can significantly streamline the setup and production process. Machines that offer intuitive controls and enhanced automation features can minimize operator error and reduce setup time, thereby boosting overall efficiency. Furthermore, consider the machine's tooling versatility; a CNC that accommodates a range of tool types can perform various functions, making it an invaluable asset for diverse manufacturing needs.

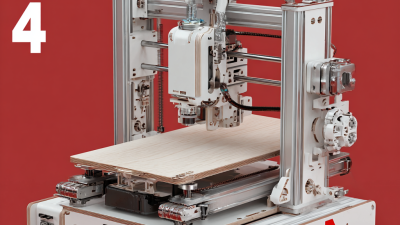

Top 10 CNC Industrial Machines for Enhanced Precision and Productivity

| Machine Model | Type | Cutting Area (mm) | Spindle Power (kW) | Accuracy (mm) | Control System |

|---|---|---|---|---|---|

| Model A | CNC Milling | 1500 x 800 | 12 | 0.01 | G-code |

| Model B | CNC Lathe | 1000 x 400 | 15 | 0.005 | Fanuc |

| Model C | CNC Router | 2000 x 1000 | 7.5 | 0.02 | Mach3 |

| Model D | CNC Plasma | 3000 x 1500 | 10 | 0.1 | LinuxCNC |

| Model E | CNC Waterjet | 1500 x 1500 | 30 | 0.05 | Siemens |

| Model F | CNC Mill-Turn | 1200 x 600 | 20 | 0.01 | Okuma |

| Model G | CNC Laser Cutter | 2600 x 1300 | 25 | 0.01 | Epilog |

| Model H | CNC EDM | 700 x 500 | 8 | 0.002 | Mitsubishi |

| Model I | CNC Router Table | 4000 x 2000 | 5 | 0.03 | ArtSoft |

| Model J | CNC Tube Cutting | 1500 x 300 | 9 | 0.1 | Lantek |

Top 10 CNC Industrial Machines for Different Applications

CNC industrial machines have revolutionized the manufacturing landscape, providing unmatched precision and efficiency across various sectors. Different applications require tailored solutions, and the versatility of CNC technology makes it adaptable for a wide range of industrial needs. For instance, machining centers are remarkable for their ability to perform milling, drilling, and tapping operations in one setup, making them ideal for complex parts in the automotive and aerospace industries. In contrast, CNC lathes excel at producing cylindrical components with high accuracy, serving sectors such as plumbing, construction, and manufacturing of rotating parts.

Additionally, CNC plasma cutting machines are essential for metal fabrication, allowing for the precise cutting of sheets and plates in manufacturing and construction applications. Router machines, on the other hand, are perfect for woodwork and composite material shaping, catering to the furniture and signage industries. Each type of CNC machine brings unique advantages, ensuring that companies can enhance productivity while meeting the specific demands of their market, whether it be in intricate designs, rapid production speeds, or handling large volumes of materials. The adaptability of CNC technology underscores its significance in driving innovation and productivity across diverse manufacturing environments.

Benefits of Using CNC Machines in Manufacturing Processes

CNC machines have revolutionized manufacturing processes, providing unparalleled benefits that enhance precision and productivity. According to a report by Deloitte, companies that adopt CNC technology can increase their operational efficiency by up to 25%, significantly reducing lead times and costs. This is primarily due to CNC machines' ability to perform intricate designs with remarkable accuracy, minimizing the margin of error that often accompanies manual machining. With their advanced programming and automated capabilities, these machines ensure consistent output quality and enable manufacturers to meet stringent industry standards.

In addition to precision, the use of CNC machines in manufacturing processes contributes to productivity gains. A study from the International Journal of Advanced Manufacturing Technology highlights that CNC machining can boost production rates by 50% compared to traditional methods. This increase stems from the machines' ability to operate continuously for extended periods with minimal human intervention, allowing facilities to maximize output while reducing labor costs. Furthermore, the flexibility of CNC machines enables manufacturers to easily adapt to changing market demands and complex project requirements, reinforcing their competitive edge in the industry.

Top 10 CNC Industrial Machines for Enhanced Precision and Productivity

This chart illustrates the precision in microns for the top 10 CNC industrial machines, showcasing their capabilities in manufacturing processes. Enhanced precision leads to improved productivity and efficiency in various applications.

Future Trends in CNC Technology and Automation

As the manufacturing landscape evolves, the future of CNC technology is poised for transformative advancements that will significantly enhance precision and productivity. One of the most notable trends is the integration of artificial intelligence and machine learning into CNC systems. These technologies enable machines to learn from past operations, optimizing processes in real time and reducing the potential for human error. By leveraging predictive analytics, manufacturers can better anticipate maintenance needs and minimize downtime, thus ensuring continuous productivity.

Another critical trend is the rise of automation and robotics within CNC machining. The combination of automated systems with CNC machines streamlines production workflows, allowing for faster turnaround times without sacrificing quality. Collaborative robots, or cobots, are becoming increasingly common on shop floors, working alongside human operators to improve efficiency and safety. Additionally, advancements in IoT (Internet of Things) connectivity facilitate remote monitoring and control of CNC machinery, further enhancing operational oversight and data collection. This interconnectedness not only boosts productivity but also paves the way for smarter manufacturing environments.

Related Posts

-

Unlocking Precision: How CNC Industrial Machines Revolutionize Manufacturing Efficiency

-

Top Strategies for Choosing the Best CNC Router for Your Business Needs

-

Top 7 Reasons Why CNC Industrial Machines Are Revolutionizing Global Manufacturing Efficiency

-

Unveiling the Technical Specifications of the Best CNC Machine for Precision Engineering

-

7 Amazing Features of the Best 3D CNC Machine You Need to Know

-

Unlocking the Future of Best CNC Machine Industrial in 2025 Strategies for Global Buyers