Top 10 Cooling Tower Types and Their Benefits?

cooling towers play a crucial role in industrial cooling systems. They effectively dissipate heat from various processes. According to Jack Thompson, a noted expert in the cooling tower industry, “Choosing the right cooling tower improves energy efficiency significantly.” His insights underline the importance of understanding different tower types.

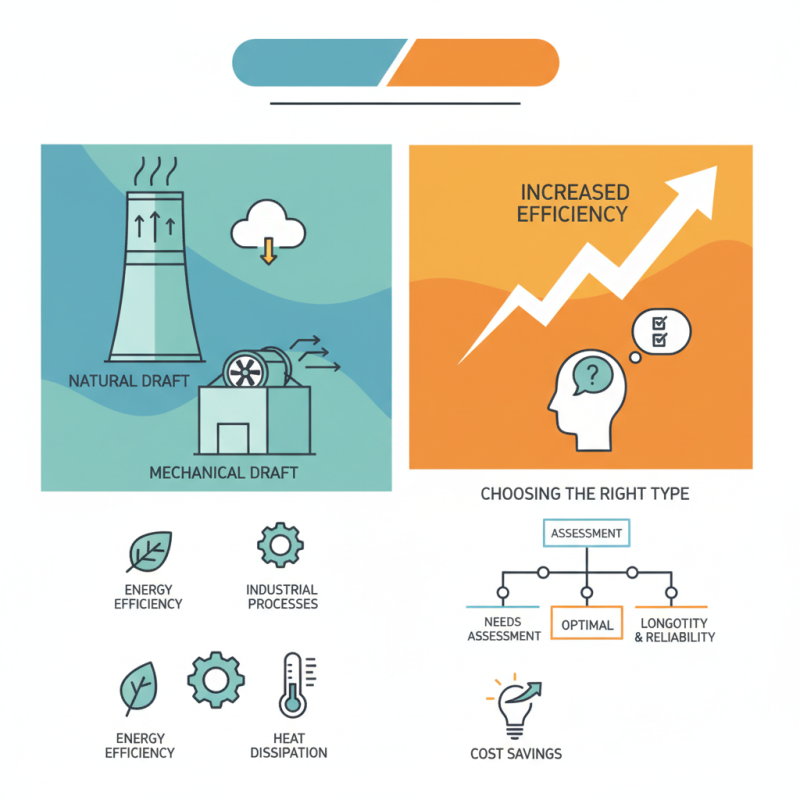

There are several types of cooling towers, each with unique advantages. Some designs excel in energy-efficient operations, while others are more compact and easier to install. For instance, a natural draft cooling tower relies on airflow to function. This type may lack the mechanical complexity of forced draft towers, but can also be less flexible in terms of location.

Companies often grapple with choosing the best solution. A wrong decision may lead to unnecessary costs and inefficiencies. Evaluating specific needs is essential. Cooling towers must fit within operational parameters, ensuring longevity and performance. Overlooking details can affect overall system reliability.

Overview of Cooling Towers and Their Applications

Cooling towers play a critical role in various industries. They remove heat from water in cooling systems. This process is essential for power plants, manufacturing facilities, and HVAC systems. According to a report by the International Energy Agency, cooling towers account for nearly 30% of global energy consumption in cooling applications. Their efficiency directly impacts energy costs and sustainability efforts.

There are several types of cooling towers, including wet and dry cooling towers. Each type has unique benefits and applications. Wet cooling towers offer better efficiency in high-temperature environments. They can dissipate heat effectively, but they require consistent water supply. Dry cooling towers, on the other hand, consume less water but may have lower heat transfer efficiency. The choice of tower type depends on specific operational needs and environmental conditions.

Despite their advantages, cooling towers face challenges. Maintenance can be costly, particularly if not conducted regularly. Additionally, the potential for water quality issues raises concerns. Local regulations concerning emissions and water use also influence operations. As industries strive for sustainability, the design and operation of cooling towers will need to evolve continually. Balancing performance and environmental impact is crucial for future advancements.

Different Types of Cooling Towers and Their Design Features

Cooling towers are essential for many industrial processes. They help dissipate heat, ensuring systems run efficiently. Various types of cooling towers have unique designs and features that suit different needs. Understanding these designs can aid in making the right choice.

One common type is the natural draft cooling tower. It uses natural air movement to circulate cooling water. These towers often have a hyperbolic shape. This design allows for efficient airflow and cooling. Another type is the induced draft cooling tower. It relies on fans to pull air through the tower. This design is usually more compact than the natural draft type and can be more adaptable.

Some cooling towers feature counterflow designs. Here, water flows down against the upward airflow. This setup enhances heat exchange effectiveness. On the other hand, crossflow designs allow water to flow horizontally while air moves vertically. While both designs have their advantages, choosing the right one is not always clear-cut. It often demands careful consideration of specific needs and conditions.

Advantages of Each Cooling Tower Type

Cooling towers are essential in industrial processes for heat rejection. The right type can enhance efficiency while minimizing energy costs. The most common types include natural draft, forced draft, and hybrid cooling towers. Each has unique benefits suited for various applications.

Natural draft cooling towers utilize buoyancy. They require no fans, leading to lower operational costs. According to industry reports, they can reach efficiencies up to 90%. However, they need significant real estate and may not fit all sites.

Forced draft towers, on the other hand, use fans for air circulation. This design allows for compact installations. They are known for quick cooling and can manage fluctuations better. However, these systems can be noisier. Hybrid cooling towers combine both principles. They offer flexibility and can save on water usage, but their complexity may lead to maintenance challenges.

Factors to Consider When Choosing a Cooling Tower

When selecting a cooling tower, several factors require attention. The size of the cooling tower is critical. It must align with the specific heat load and water flow requirements of your facility. An undersized tower can lead to insufficient cooling, affecting efficiency and performance. Industry reports suggest that improper sizing can result in energy wastage of up to 20%.

The type of cooling tower also plays a crucial role. There are various configurations, including open-circuit, closed-circuit, and hybrid designs. Each has unique benefits and applications. For example, open-circuit towers are often more cost-effective but may need more frequent maintenance. Conversely, closed-circuit towers are better for applications requiring water purity, though they typically carry a higher initial cost.

Tip: Evaluate your facility's specific cooling needs before making a decision. Work with professionals who can provide insight into energy efficiency. Also, consider the tower's noise level, especially in urban areas. Many cooling towers operate at sound levels that could exceed local regulations, leading to fines. Ensuring compliance can be both a legal and operational issue your facility must address.

Maintenance and Efficiency of Cooling Towers

Cooling towers play a crucial role in many industrial processes. Their efficiency affects overall operations. Regular maintenance is paramount for optimal performance. Neglected towers can lead to operational failures. This results in unnecessary costs and downtime. Cleaning is not just about aesthetics; it improves efficiency. Build-up of dirt and debris reduces heat exchange efficiency.

Inspecting fans and motors regularly is essential. It ensures they operate within proper parameters. Unusual sounds can indicate underlying issues. Address these concerns promptly. Additionally, water quality affects cooling efficiency. Algae growth and mineral deposits are common issues. Regular water treatment minimizes these problems and extends tower life.

Temperature fluctuations can also impact performance. Towers need to be monitored for any irregular changes. Unstable temperature can hint at malfunctioning components. Keeping meticulous records helps identify trends over time. Reactive maintenance is often too late. Proactive approaches can save resources and enhance efficiency. Being mindful of these details can make or break operational reliability.