Digital Insights into the Best CNC Metal Machining Techniques

The advent of digital technologies has revolutionized the landscape of CNC metal machining, with industry reports indicating a projected growth of the CNC machining market to $100 billion by 2025. As manufacturers seek to enhance precision and efficiency in metalworking, the integration of advanced techniques and digital insights has become paramount.

According to the Association for Manufacturing Technology, over 70% of manufacturers are now adopting CNC metal machining to improve their production capabilities and reduce waste. This digital transformation not only streamlines workflows but also enables real-time data analysis, empowering businesses to make informed decisions that elevate their machining processes.

The following discussion delves into the best CNC metal machining techniques, underscoring their significance in maximizing productivity and maintaining a competitive edge in the manufacturing sector.

Understanding the Basics of CNC Metal Machining Techniques

The adoption of automation in the metal forming process is increasingly prevalent, significantly enhancing market demand. With the rise of robotics and the integration of automated systems, traditional metal machining techniques are evolving. CNC technology plays a crucial role in this transformation, providing manufacturers with the precision and efficiency needed for modern production requirements. As industries demand higher accuracy and lower operational costs, CNC machines are becoming essential in transitioning from conventional practices to more advanced automated solutions.

Recent collaborations, such as the formation of a laser cutting research alliance, exemplify the industry's shift towards innovative machining technologies. With the guiding support from research institutions, companies are developing cutting-edge 5-axis laser equipment, aiming to create significant economic value. This focus on technological advancement not only enhances operational capabilities but also drives the market towards more sustainable practices, ultimately reshaping the landscape of CNC metal machining.

Choosing the Right CNC Machine for Your Metal Fabrication Needs

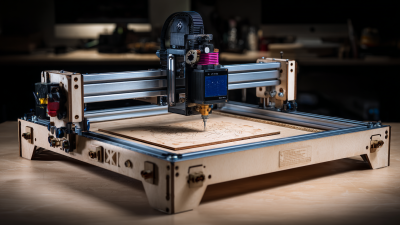

When selecting the right CNC machine for your metal fabrication needs, it is essential to consider several factors that influence efficiency and precision. First, you should evaluate the specific types of materials you will be working with, such as aluminum, steel, or titanium, as different machines have varying capabilities and tolerances. Additionally, the complexity of the designs you intend to produce should guide your choice; machines with higher spindle speeds and multi-axis capabilities can significantly enhance your ability to create intricate components.

Another critical aspect to consider is the scale of your operations. For small-scale projects, a high-quality desktop CNC might suffice, while larger operations may necessitate industrial-grade machines that can handle heavier workloads and larger pieces of material. Budgetary constraints also play a role, as CNC machines come in a wide range of prices based on features and specifications. Lastly, don't overlook the importance of post-purchase support and software compatibility, as these can greatly impact your machine's performance and ease of use in the long run.

Digital Insights into CNC Metal Machining Techniques

This chart showcases the most commonly used CNC machining techniques in metal fabrication along with their effectiveness ratings based on industry feedback.

Essential Tools and Software for Effective CNC Metal Machining

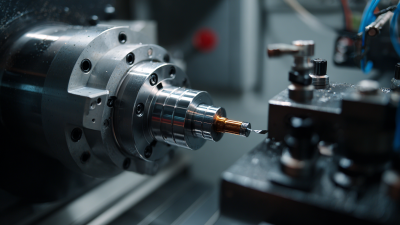

When it comes to CNC metal machining, having the right tools and software is essential for achieving high precision and efficiency. One of the most crucial tools is the CNC machine itself, which can vary in type depending on the specific requirements of a project. For instance, milling machines, lathes, and laser cutters each offer unique advantages suited to different machining tasks. Selecting a machine that aligns with the material and desired outcome is critical; this includes considering factors like size, complexity, and tolerances.

Alongside the hardware, advanced software plays a pivotal role in CNC machining. Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software are indispensable for creating detailed designs and generating machining instructions. These programs allow machinists to simulate the machining process, thus optimizing tool paths and minimizing waste. Furthermore, integration with CNC controllers enhances the machining process, providing real-time feedback and adjustments. By leveraging these essential tools and software, manufacturers can streamline operations, improve product quality, and maintain a competitive edge in the industry.

Optimizing CNC Machining Processes for Efficiency and Precision

The integration of digital technologies in CNC machining processes is transforming the landscape of manufacturing efficiency and precision. As highlighted by recent industry reports, the CNC machinery market is projected to significantly grow, reaching a valuation of approximately $21.69 billion by 2033, with a compound annual growth rate (CAGR) of 5.7% from 2025. This growth is indicative of a broader shift towards Industry 4.0, where digitalization and smart technology play a critical role in enhancing operational capabilities.

In particular, the application of digital twins has emerged as a key strategy for optimizing CNC machining operations. By creating accurate virtual replicas of physical assets, manufacturers can simulate processes, predict outcomes, and enhance precision. This approach has been linked to improvements in machining accuracy to within 5 microns and increases in efficiency by up to three times. The adoption of these innovative techniques is not only leading to better performance metrics but is also driving companies to transition from traditional manufacturing methods to more automated and environmentally friendly solutions.

Common Challenges in CNC Metal Machining and Solutions to Overcome Them

CNC metal machining presents both opportunities and challenges for manufacturers striving to adapt to the evolving landscape of digital manufacturing. One prevalent issue faced in CNC machining is the high demand for precision and efficiency, which can lead to operational bottlenecks if not managed effectively. To overcome this, the adoption of advanced machine tools and automated processes is essential. These improvements not only enhance productivity but also reduce the environmental footprint, aligning with the industry's shift towards more sustainable practices.

Tips: Embrace smart manufacturing technologies, such as IoT-enabled machines, to monitor and optimize your processes in real-time. This technology can significantly reduce downtime and improve overall efficiency. Additionally, integrating robust data analytics into your operations can offer insights that lead to better decision-making and innovation in machining techniques.

Another common challenge is material selection, especially with the push for lighter and cost-effective solutions in the era of 5G and other advanced technologies. Manufacturers must stay updated on the latest materials that can provide both performance and compliance with environmental standards. By investing in research and development, companies can innovate their product offerings while ensuring that they meet market demands. Diversifying material sources can also mitigate risks associated with global supply chain disruptions.

Digital Insights into the Best CNC Metal Machining Techniques - Common Challenges in CNC Metal Machining and Solutions to Overcome Them

| Technique | Common Challenges | Solutions |

|---|---|---|

| Milling | Tool wear | Regular tool inspection and timely replacement |

| Turning | Vibration during operation | Optimize cutting speed and feed rates |

| Drilling | Drill bit breakage | Use of appropriate cooling and feed rates |

| Electrical Discharge Machining (EDM) | Surface finish issues | Adjust parameters to improve spark gap |

| Laser Cutting | Material burn-through | Adjust laser power and speed settings |

Related Posts

-

20 Best CNC Metal Solutions for Precision Engineering

-

Understanding Import Export Certifications for Buying the Best CNC Laser Cutter Globally

-

Unlocking Creativity with CNC Wood Carving Machines and Their Unique Advantages

-

Exploring the Top Alternatives to the Best CNC Laser Engraver for Your Business Needs

-

Unveiling the Technical Specifications of the Best CNC Machine for Precision Engineering

-

Unlocking Precision: A Comprehensive Guide to the Best CNC Machine for Home Use with Technical Specs!