5 Essential Tips for Choosing the Best Desktop CNC Machine for Your Business

As the demand for precision manufacturing continues to rise, more businesses are turning to advanced technologies to maintain a competitive edge. According to a recent report by the International Federation of Robotics, the global market for CNC machines is expected to reach $96.5 billion by 2025, with desktop CNC machines increasingly popular among small to medium enterprises due to their cost efficiency and versatility. These machines provide the ability to create intricate designs in various materials, from wood to metal, making them an essential tool in modern workshops. However, selecting the right desktop CNC machine can be daunting with so many options available. In this blog, we will outline five essential tips to simplify your decision-making process and ensure that you choose a machine that aligns perfectly with your business needs and enhances your production capabilities.

Key Factors Impacting the Selection of a Desktop CNC Machine for Small Businesses

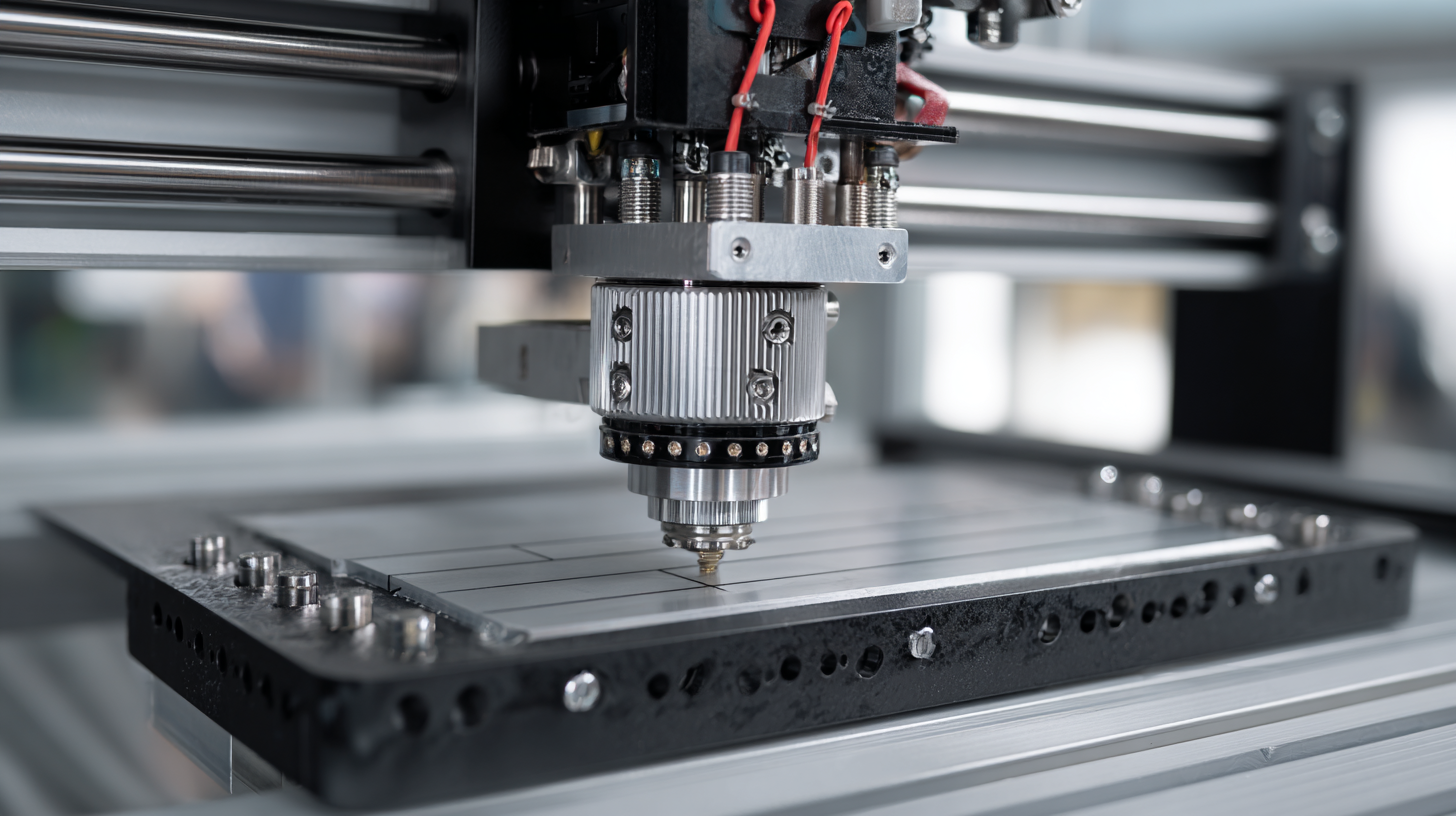

When selecting a desktop CNC machine for your small business, several key factors come into play that can significantly impact your decision. First and foremost, consider the machine's precision and capabilities. Look for a model that offers high accuracy and can handle the specific materials you plan to work with. A CNC machine with a higher resolution is essential for producing intricate designs and ensuring quality workmanship.

Another critical factor is the size of the workspace. Assess the dimensions of your shop area and the types of projects you intend to undertake. A compact machine may suit limited spaces, but ensure it still has enough capacity for your creative endeavors. Additionally, evaluate the software compatibility. Choosing a machine that seamlessly integrates with your existing design software can streamline your workflow and improve efficiency.

Lastly, consider the after-sales support and warranty offered by the manufacturer. Good customer service can make a significant difference, especially when technical issues arise. Investing in a machine with comprehensive support can save you time and money in the long run, allowing your small business to flourish without unnecessary setbacks.

Understanding the Precision and Accuracy Standards in CNC Machining

When selecting a desktop CNC machine for your business, understanding precision and accuracy is paramount. The performance of CNC machines is heavily reliant on how well they can maintain standards of precision in their operations. This involves factors such as the machine’s ability to maintain tight tolerances and the overall quality of components used in their construction. Moreover, advancements in technologies like touch probing systems are enhancing the capability of CNC machines to collect data automatically, which can significantly improve accuracy and efficiency in manufacturing processes.

The integration of innovative systems, such as precision probes, into CNC machining is revolutionizing the way operations are carried out. These probes enable machines to gather real-time data regarding the dimensions and surface roughness of components, ensuring that each finished product meets exact specifications. Additionally, as the market for high precision mechanical machine components continues to grow, it is essential for businesses to adopt machines that can consistently deliver superior accuracy and maintain high-quality standards. Emphasizing these aspects in your selection process will help ensure that the CNC technology you choose can help optimize production while minimizing costs.

Evaluating Cost Efficiency: ROI of Desktop CNC Machines in Manufacturing

When evaluating the cost efficiency of desktop CNC machines for your business, understanding their return on investment (ROI) is crucial. Recent industry trends indicate that automated CNC processes are essential for enhancing productivity and competitiveness in manufacturing. According to a report by a leading market analysis firm, companies that integrate CNC automation can expect an average productivity boost of 30-50%. This increase directly correlates to reduced labor costs and accelerated production times, which are vital for small and medium enterprises looking to remain competitive.

Furthermore, collaborative robots (cobots) are playing a significant role in small business automation. By streamlining tasks such as material handling and tool changes, cobots not only improve operational efficiency but also lower the barriers to automation that many SMEs face. Research suggests that businesses utilizing cobots see a significant reduction in downtime and an increase in overall efficiency by upwards of 25%. As industries increasingly adopt these technologies, the financial rationale for investing in desktop CNC machines becomes more compelling, offering a pathway to enhanced profitability and growth.

5 Essential Tips for Choosing the Best Desktop CNC Machine for Your Business - Evaluating Cost Efficiency: ROI of Desktop CNC Machines in Manufacturing

| Feature | Description | Cost (USD) | Expected ROI (Years) |

|---|---|---|---|

| Cutting Area | Size of the workspace for machining | $2,000 | 2 |

| Precision | The accuracy of the machine's movements | $3,500 | 3 |

| Material Compatibility | Types of materials the machine can process | $1,800 | 1.5 |

| Software Support | Compatibility with design software | $2,200 | 2.5 |

| Operating Costs | Maintenance and operational expenses | $900/year | N/A |

Assessing Software Compatibility for Optimal CNC Machine Performance

When selecting a desktop CNC machine for your business, one of the most critical factors to consider is software compatibility. The right software can significantly enhance your machine's performance, ensuring your production process is efficient and precise. Before purchasing a CNC machine, it's essential to evaluate the types of software that are compatible with the system. Look for machines that support popular CAD/CAM software platforms, as this will provide you with a versatile toolkit for designing and manufacturing your projects.

Furthermore, consider the user interface and ease of integration of the software with the CNC machine. A user-friendly interface can make a world of difference, particularly for teams that may not have extensive technical expertise. Check if the software offers tutorials, support, and regular updates to keep your operations running smoothly. Additionally, the ability to customize features or plugins can be a bonus, allowing you to adapt the machine’s capabilities as your business needs evolve. Overall, ensuring that your desktop CNC machine is compatible with robust software will maximize its potential, leading to superior output and productivity.

Exploring Market Trends: The Growth of CNC Machining in China and Beyond

The CNC machining industry is experiencing a remarkable surge, particularly within the Chinese market, which is indicative of global trends. The worldwide market for CNC machines is projected to expand from $101.22 billion in 2025 to an astonishing $195.59 billion by 2032, achieving a compound annual growth rate (CAGR) of 9.9%. This rapid growth reflects the increasing demand for precision manufacturing and automation across various sectors.

Moreover, the CNC machine tool market follows a similar trajectory, with estimates suggesting a rise from $27.16 billion in 2025 to $44.64 billion by 2033, marking a CAGR of 6.4%. Such data highlights the vast opportunities available for businesses looking to invest in advanced manufacturing technologies. As companies increasingly prioritize efficiency and output quality, the relevance of sophisticated CNC systems only intensifies, paving the way for further innovation within the industry.

As the landscape of CNC machining evolves, aligning with market trends and selecting the right machinery becomes crucial for businesses. With a forecasted CAGR of 6.0% for the carbide tools segment, the emphasis on precision cutting tools complements this broader trend, making it essential for businesses to stay informed and adaptive in this fast-paced environment.