10 Essential Tips for Choosing the Best Laser Engraving Machine

Choosing the right laser engraving machine can be a game-changer for both hobbyists and professionals alike. With the rapid advancements in technology, the market is flooded with various models that boast unique features and capabilities. However, selecting the best laser engraving machine for your specific needs requires careful consideration of multiple factors. From the type of materials you plan to engrave to the machine's size and power, understanding these elements can significantly influence your engraving quality and efficiency.

In this article, we will delve into ten essential tips that will guide you in selecting the perfect laser engraving machine tailored to your projects. Whether you are creating intricate designs on wood, glass, or metal, knowing what to look for can help you make an informed decision. By exploring critical aspects such as budget, ease of use, and customer support, you will be better equipped to navigate the vast array of options available. Ultimately, the right laser engraving machine can enhance your creative potential and streamline your engraving process, leading to stunning results every time.

Understanding Different Types of Laser Engraving Machines

When selecting a laser engraving machine, understanding the different types available on the market is crucial to making an informed decision. The two primary types of laser engraving machines are CO2 and fiber lasers. CO2 lasers are versatile tools predominantly used for engraving a variety of non-metal materials, including wood, acrylic, leather, and glass. They operate at a wavelength of 10.6 micrometers, making them ideal for precise cuts and detailed engravings. According to industry reports, CO2 lasers account for about 70% of the laser engraving market due to their affordability and broad applications.

On the other hand, fiber lasers are better suited for marking and engraving metals and high-density materials. These lasers operate at a much shorter wavelength, around 1.06 micrometers, allowing for more efficient energy concentration on reflective surfaces. Market analysis indicates that the fiber laser segment is growing rapidly, projected to reach a compound annual growth rate (CAGR) of 10.8% through 2026. This makes them an attractive option for industries requiring durability and longevity in their engravings, such as automotive and aerospace manufacturing. Understanding the strengths and limitations of these laser types can greatly enhance your productivity and ensure that you choose the best machine for your specific engraving needs.

Laser Engraving Machine Types and Their Features

Key Features to Consider When Choosing a Laser Engraving Machine

When selecting a laser engraving machine, understanding the key features is crucial to ensure that the investment aligns with both your current needs and future potential. One of the primary considerations is the laser type; CO2 lasers are widely used for materials like wood, acrylic, and glass, while fiber lasers excel in marking metals. According to industry reports, CO2 laser systems dominate around 60% of the market share due to their versatility and effectiveness across various materials, making them a popular choice among both hobbyists and professionals.

Another vital aspect to consider is the machine's power and speed. The engraving speed can significantly impact productivity, particularly in commercial settings. For instance, machines with greater wattage can handle thicker materials and provide faster engraving times. Data from recent market analysis indicates that businesses have seen a productivity increase of up to 30% when upgrading to higher-powered systems. Additionally, bed size is important; a larger engraving area allows for working on bigger projects or multiple items at once, streamlining workflow and efficiency. Ensuring that your chosen laser engraving machine has the right balance of power, speed, and size can greatly influence your success.

Evaluating Your Project Needs and Material Compatibility

When it comes to selecting a laser engraving machine, understanding your project needs and material compatibility is paramount. Different materials demand distinct laser types and power settings for optimal engraving. For instance, acrylic and wood generally require CO2 lasers due to their ability to efficiently cut and engrave non-metal surfaces. Conversely, metal projects necessitate fiber lasers which can effectively handle reflective surfaces and thicker materials.

According to a report from the Laser Institute of America, the growing demand for precision engraving across various sectors, including manufacturing and crafts, highlights the importance of matching the right laser technology to your specific needs.

In evaluating material compatibility, consider the type of material you will predominantly work with. A recent survey by Markets and Markets indicated that the laser engraving industry is projected to grow significantly, driven by advancements in technology and increased interest from small businesses in custom engraving services. Compatibility not only relates to the material type but also the thickness and finish, which can affect the power and speed settings required for effective engraving.

By understanding these aspects, you can ensure that the laser engraving machine you choose will deliver the desired results, maximizing both productivity and quality in your projects.

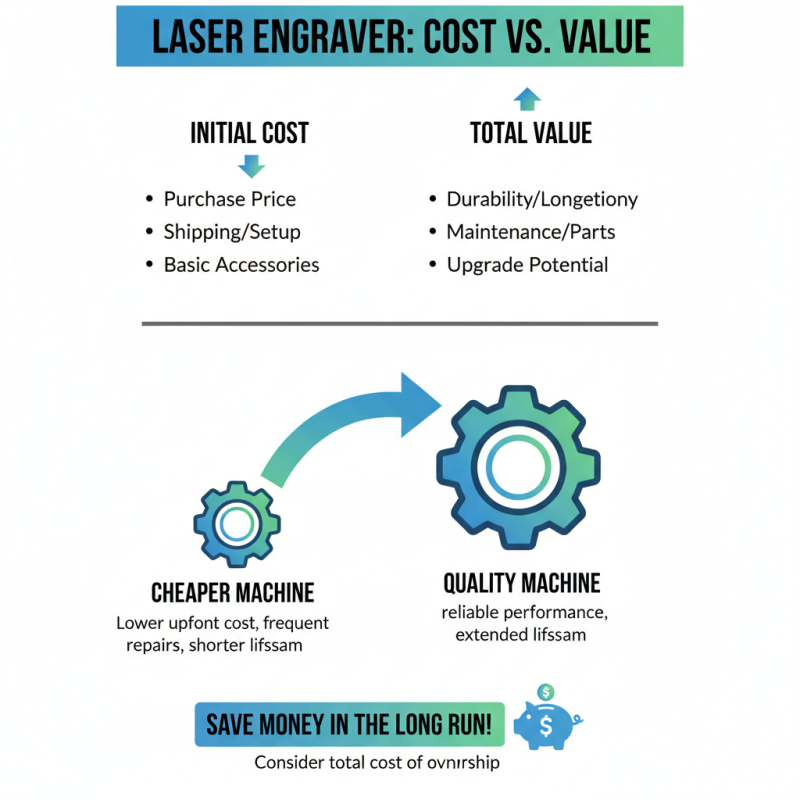

Assessing Budget and Long-Term Value for Laser Engraving Machines

When selecting a laser engraving machine, assessing your budget and its long-term value is crucial. Many buyers often focus solely on the initial purchase price, but it’s essential to consider the total cost of ownership. This includes maintenance, replacement parts, and any necessary upgrades in the future. A more expensive machine may offer superior durability and capabilities that could save you money and time in the long run.

One of the key tips for evaluating your options is to analyze the machine's operational efficiency. Look for models that provide a balance between power consumption and output quality. Machines that are designed for high-performance engraving tasks might require a higher initial investment but can lead to greater productivity, thus maximizing your return on investment. Additionally, consider the warranty and support offered by the manufacturer, as this can significantly impact your long-term costs.

Another important aspect is to factor in the versatility of the engraving machine. A model that can handle a variety of materials will not only enhance your creative possibilities but also save you from needing to buy additional machines. This versatility can lead to better service offerings, allowing you to cater to a broader clientele and increasing your revenue potential over time. By focusing on these budget-related aspects, you can make a more informed decision that benefits your engraving business in the long run.

Reviewing User Feedback and Brand Reputation in the Market

When selecting a laser engraving machine, the significance of

user feedback and brand reputation cannot be overstated. According to a report by

MarketsandMarkets, the global laser engraving market is projected to grow from

$3.4 billion in 2020 to $4.7 billion by

2025, indicating a rising interest among consumers in high-quality engraving solutions. Brands that have

established a strong reputation often maintain customer loyalty, which is reflected in user reviews. An

overwhelming 70% of customers trust online reviews as much as personal recommendations,

highlighting the critical role user feedback plays in decision-making.

Moreover, industry surveys often reveal that features such as precision,

speed, and ease of use are paramount

considerations for users. A study by Research and Markets indicates that 53% of

users prioritize precision, while 47% consider the brand's reputation for reliability essential.

This suggests that potential buyers should actively seek out machines with consistently positive feedback that

not only emphasizes performance but also long-term customer satisfaction. Engaging with online

communities and forums can provide invaluable insights into real-world experiences, helping prospective

buyers make informed choices that align with their engraving needs.

Related Posts

-

2025 How to Choose the Best CNC Laser Engraver for Your Business Needs

-

Unlocking the Future of Best CNC Machine Industrial in 2025 Strategies for Global Buyers

-

5 Key Benefits of Investing in Wood CNC Machines for Global Manufacturers

-

5 Essential Tips for Choosing the Best Desktop CNC Machine for Your Business

-

Unlocking the Future of Precision Fabrication with CNC Laser Cutters

-

Unveiling the Technical Specifications of the Best CNC Machine for Precision Engineering