10 Exceptional CNC Parts to Elevate Your Manufacturing Process

In today's highly competitive manufacturing landscape, the importance of precision and efficiency cannot be overstated. A recent report by MarketsandMarkets indicates that the global CNC machining market is expected to reach $100 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.9%. As businesses strive to elevate their production capabilities, the integration of exceptional CNC parts has emerged as a critical strategy. These components not only enhance accuracy and repeatability in machining processes, but they also significantly impact overall operational efficiency.

This blog delves into ten outstanding CNC parts that can transform manufacturing operations, providing insights into how they contribute to superior performance and competitive advantage in a rapidly evolving market.

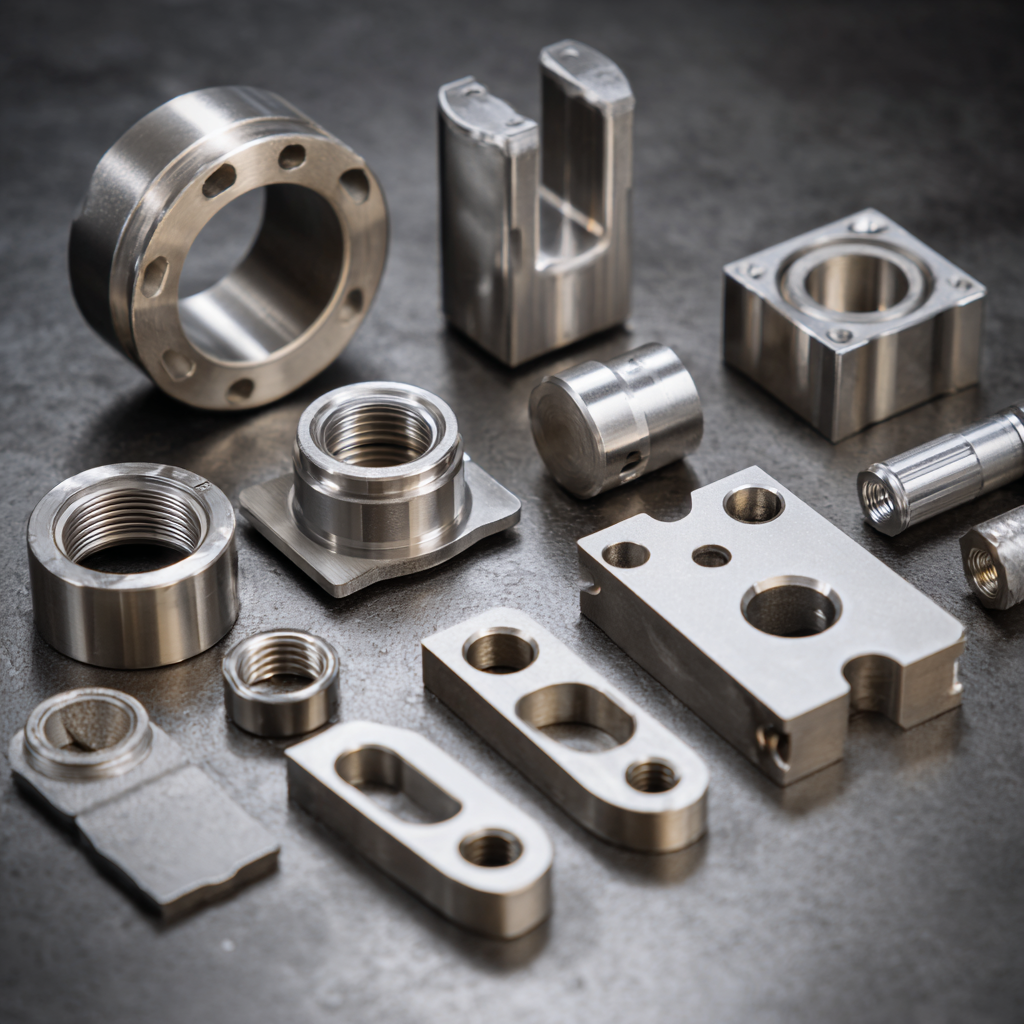

CNC Machined Components: A Side-by-Side Comparison of Precision and Material Flexibility

In the realm of modern manufacturing, CNC machined components play an essential role in achieving high precision and material flexibility. One of the standout features of CNC machining is its ability to work with a diverse array of materials—including metals, plastics, and composites—while consistently maintaining tight tolerances. This adaptability allows manufacturers to select the best material for each specific application, resulting in parts that not only fit their functional needs but also enhance overall performance and durability.

When comparing different CNC machined components, precision becomes a critical factor. High-precision parts are vital in industries such as aerospace and medical devices, where even the slightest deviation can have significant consequences. CNC technology ensures intricate designs can be produced with remarkable accuracy, making it possible to create complex geometries that were once impossible with traditional machining techniques. This combination of precision and material versatility makes CNC machining an indispensable asset in elevating manufacturing processes, allowing for greater innovation and efficiency in producing exceptional parts.

Exploring the Top CNC Parts: The Best Options for Different Manufacturing Needs

When it comes to manufacturing, choosing the right CNC parts is crucial for

optimizing efficiency and quality. Different manufacturing needs require specific components that can significantly influence the overall process.

For instance, recent reports indicate that small CNC machines have gained popularity for their versatility and compact size, making them ideal for

smaller workshops and various applications. These machines not only cater to hobbyists but also are suitable for production-level work in specific

industries, reflecting a broader trend towards automation and precision in manufacturing.

Additionally, the growth in on-demand manufacturing options suggests that the selection of CNC parts is becoming more specialized. Beyond traditional suppliers, manufacturers are increasingly turning to alternative platforms that provide custom part solutions. These developments are underpinned by data showing that the market for CNC parts is projected to expand, as businesses seek cost-effective and

reliable options to fulfill their unique manufacturing requirements. This shift emphasizes the importance of evaluating all available options—whether

it be through innovative alternatives or advanced machining techniques—to stay competitive in an evolving manufacturing landscape.

Material Matters: Comparing the Strength and Durability of CNC Parts

When it comes to CNC parts, the choice of material significantly impacts both strength and durability, making it a crucial consideration in the manufacturing process. Common materials such as aluminum, steel, and titanium each offer distinct properties that can cater to different applications. Aluminum, for instance, is lightweight and resistant to corrosion, making it ideal for projects requiring lower weight with decent strength. On the other hand, steel is notoriously strong and durable, perfect for heavy-duty applications. For those looking for a balance between weight and strength, titanium is an excellent choice, albeit more costly.

Tips for selecting the right material for your CNC parts include first thoroughly understanding the specific requirements of your project. Consider factors such as load-bearing capacity, environmental exposure, and required finish. Additionally, evaluate the machining characteristics of each material, as some can be more challenging to work with than others, potentially increasing production time and costs. Engaging with your CNC manufacturer about these options can provide valuable insights tailored to your needs, ensuring you select the best material for optimal performance and longevity.

Comparison of Strength and Durability of CNC Parts

Cost Efficiency vs. Quality: Evaluating CNC Parts for Budget-Conscious Manufacturers

In the ever-evolving landscape of manufacturing, businesses often face the critical dilemma of balancing cost efficiency with quality when selecting CNC parts. For budget-conscious manufacturers, the challenge lies in sourcing components that not only fit within financial constraints but also meet rigorous performance standards. With a plethora of options available, making informed decisions is essential for optimizing production processes and ensuring the end product remains competitive.

A strategic approach involves evaluating the long-term benefits of investing in higher-quality CNC parts. While the initial cost may be greater, superior materials and precision engineering can lead to reduced maintenance, fewer replacements, and enhanced overall productivity. Moreover, high-quality parts often result in better tolerances and finishes, ultimately elevating the final output. On the other hand, opting for cheaper alternatives may save money upfront but can lead to increased operational costs due to higher failure rates and lower efficiency. Thus, manufacturers must carefully assess their unique needs and weigh the immediate financial implications against potential future savings, striking the right balance between cost and quality.

10 Exceptional CNC Parts to Elevate Your Manufacturing Process - Cost Efficiency vs. Quality

| CNC Part | Material | Cost ($) | Quality Rating (1-5) | Typical Usage |

|---|---|---|---|---|

| CNC Machined Bracket | Aluminum 6061 | 45 | 4 | Mounting Components |

| CNC Plate | Steel | 60 | 5 | Base Structures |

| CNC Gears | Brass | 35 | 4 | Mechanical Drives |

| CNC End Mill | Carbide | 120 | 5 | Material Removal |

| CNC Fixture | Aluminum 7075 | 80 | 4 | Work Holding |

| CNC Shaft | Carbon Steel | 50 | 4 | Rotating Components |

| CNC Nozzle | Plastic | 20 | 3 | Fluid Delivery |

| CNC Clamps | Aluminum | 15 | 4 | Holding Workpieces |

| CNC Pulley | Aluminum | 25 | 4 | Belt Drives |

| CNC Valve Body | Bronze | 55 | 5 | Fluid Control |

Innovative Design Features: How CNC Parts Stand Out in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, CNC (Computer Numerical Control) parts play a pivotal role in enhancing efficiency and precision. Innovative design features such as customized tolerances and intricate geometries enable manufacturers to push the boundaries of what is possible. According to a report by TechNavio, the global CNC machining market is expected to grow by 6% annually, driven by these advancements. This underscores the significance of leveraging state-of-the-art CNC parts to optimize production lines and maintain a competitive edge.

Tips for improving your CNC machining process include investing in the latest software that allows for more complex designs and integrating real-time monitoring systems to catch discrepancies early. Furthermore, consider utilizing advanced materials such as titanium and specialized alloys, which can withstand higher temperatures and stresses, improving overall durability. A study from Grand View Research highlights that incorporating such materials into manufacturing can lead to a reduction in operational costs by as much as 15%.

In addition, the implementation of automation in CNC machining is crucial. Automating repetitive tasks not only speeds up production but also minimizes human error, ensuring consistent quality in every piece. Research from MarketsandMarkets indicates that the automation of CNC machining can increase productivity by approximately 25%, offering a significant return on investment for manufacturers willing to modernize their processes.