The Future of Precision Crafting with Best CNC Laser Engravers

As the manufacturing landscape evolves, the demand for precision and efficiency has never been higher, particularly in the realm of CNC laser engraving. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach $117.5 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.5%. This surge is largely driven by advancements in technology and the increasing adoption of CNC laser engravers across various industries, from automotive to aerospace.

Chinese manufacturers, noted for their innovative approaches and competitive pricing, are leading the way in meeting global demands with high-quality machines. The phrase "中国智造,全球热销,品质保证" aptly encapsulates this phenomenon, highlighting China's commitment to smart manufacturing and quality assurance. As we explore the future of precision crafting, the role of CNC laser engravers becomes increasingly pivotal in redefining production processes and maximizing operational efficiency.

Chinese manufacturers, noted for their innovative approaches and competitive pricing, are leading the way in meeting global demands with high-quality machines. The phrase "中国智造,全球热销,品质保证" aptly encapsulates this phenomenon, highlighting China's commitment to smart manufacturing and quality assurance. As we explore the future of precision crafting, the role of CNC laser engravers becomes increasingly pivotal in redefining production processes and maximizing operational efficiency.

The Evolution of CNC Laser Engraving Technology and Its Impact on Crafting

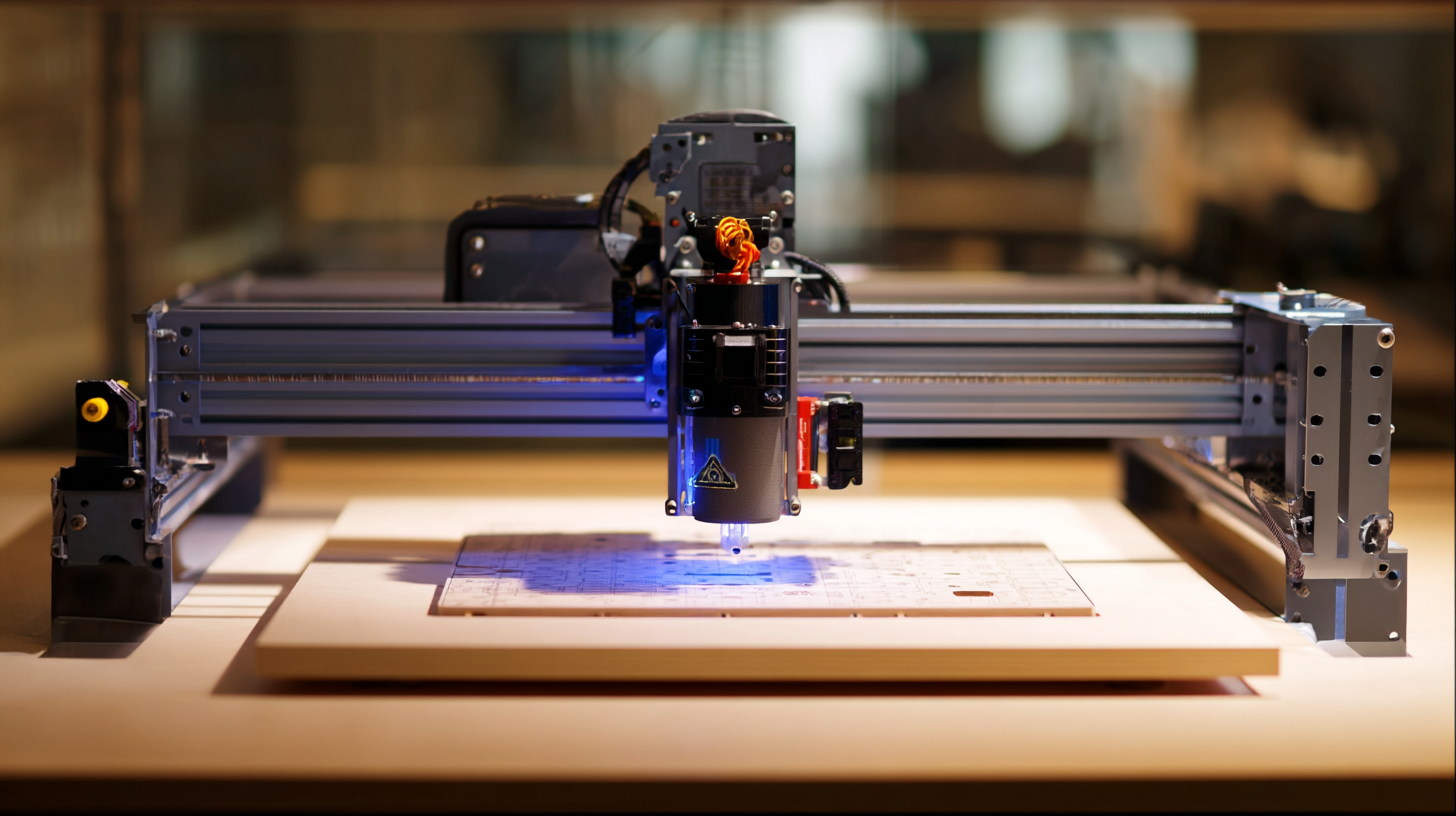

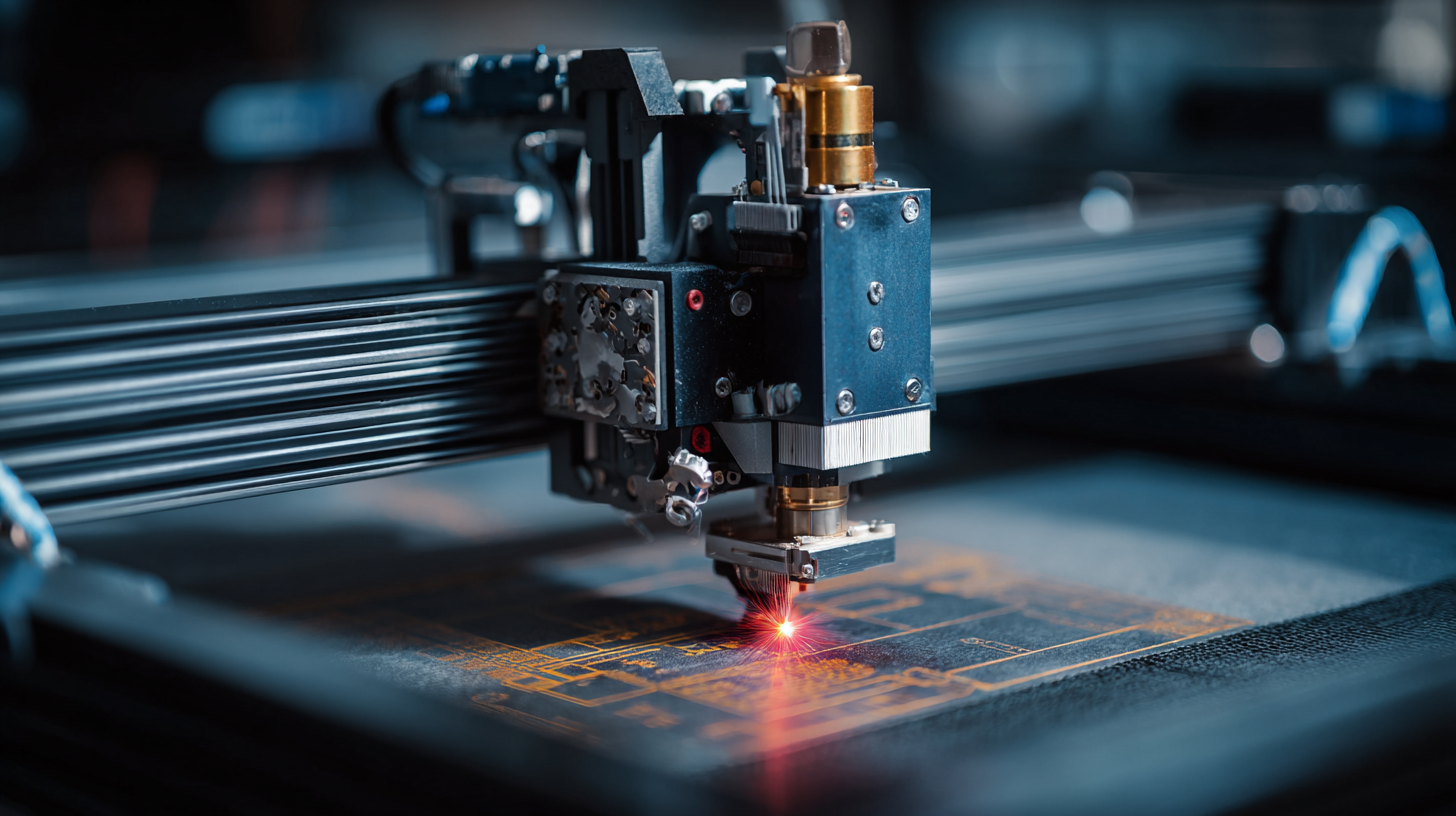

The evolution of CNC laser engraving technology has profoundly influenced the crafting landscape, providing artisans with tools that enhance precision and creativity. As the market for wooden laser cutting machines expands, with a noticeable shift toward advanced technologies like CO2 and diode laser systems, the capabilities of these machines have significantly improved. The rise of these technologies enables makers to deliver intricate designs, whether for signage or decorative frames, with unparalleled accuracy and speed.

Geographic trends reveal that regions such as North America and Europe are at the forefront of this technology's adoption. As demand grows, the market has seen innovations tailored to specific applications, allowing craftsmen to explore new avenues for expression. With ongoing advancements in laser engraving technology, the possibilities for personalization and detail in crafted items are virtually limitless, marking a new era for creators looking to elevate their work through precision crafting.

Key Features to Look for in High-Quality CNC Laser Engravers

When selecting a high-quality CNC laser engraver, several key features can significantly enhance your crafting experience and outcomes. First and foremost, the laser power is critical; it determines the thickness of materials you can engrave or cut efficiently. For instance, a machine with at least 40 watts of power is ideal for most applications, allowing for versatility with various mediums such as wood, acrylic, and metals. Additionally, a higher wattage generally translates to faster cutting speeds, making it essential for time-sensitive projects.

Another essential feature is the software compatibility that supports user-friendly design processes. High-quality CNC laser engravers come with advanced design software that offers a variety of customization options, enabling artisans to produce intricate and personalized designs effortlessly. Moreover, a robust cooling system is vital for maintaining optimal performance during extended use, as it prevents overheating and prolongs the lifespan of the laser. By focusing on these features, crafters can ensure they invest in a CNC laser engraver that meets both their creative needs and operational demands.

Top Strategies for Optimizing Your CNC Laser Engraving Workflow

In the rapidly evolving world of precision crafting, optimizing your CNC laser engraving workflow is essential for achieving efficient production and high-quality results. Recent industry reports indicate that businesses leveraging advanced CNC laser technology can increase their productivity by up to 30%. This efficiency boost is largely attributed to streamlined operations and enhanced automation capabilities offered by modern engraving systems. Incorporating real-time monitoring and performance analytics into your workflow can significantly reduce downtime and improve output consistency.

Additionally, implementing best practices such as material training and tool path optimization can further enhance the engraving process. According to a study by the National Association of Manufacturers, companies that regularly invest in training for their CNC operators see productivity gains of approximately 25%. It’s crucial to ensure that staff are well-versed in the functionalities of their CNC laser engravers, as this knowledge directly contributes to reducing errors and maximizing the machine's capabilities. As we move forward, embracing these strategies will not only refine the engraving process but also position businesses for long-term success in the competitive landscape of precision crafting.

The Future of Precision Crafting with Best CNC Laser Engravers

Creative Applications of CNC Laser Engraving in Various Industries

The rapid evolution of CNC laser engraving technology is transforming various industries, allowing for innovative applications that were previously unimaginable. According to industry forecasts, the global laser processing equipment market size is projected to soar from $28.51 billion in 2025 to an impressive $64.39 billion by 2032, demonstrating a robust compound annual growth rate (CAGR) of 12.3%. This growth can be attributed to the increasing demand for precision in manufacturing and customization across multiple sectors, including automotive, aerospace, and consumer goods.

In parallel, the portable engraving system market is also experiencing significant growth, with projected revenue reaching USD 5.90 billion by 2034, marking a CAGR of 9.42%. The rise of portable systems caters to the needs of small businesses and hobbyists, making advanced laser technology more accessible. This shift not only enhances craftsmanship but also fosters creativity, enabling artisans to explore intricate designs and personalized products that resonate with modern consumers. As industries continue to embrace these advancements, the future of precision crafting appears bright, presenting endless possibilities for innovation and artistic expression.

Maintaining and Troubleshooting Your CNC Laser Engraver for Longevity

Maintaining and troubleshooting your CNC laser engraver is crucial for ensuring its longevity and optimal performance. According to a recent report from the International Society of Automation, nearly 30% of laser engraver downtimes are attributed to improper maintenance. Regular upkeep not only extends the lifespan of the equipment but also minimizes operational costs. Simple tasks like cleaning the lens and mirrors can improve efficiency by up to 15%, as they prevent debris accumulation that can distort the laser beam.

Tip: Always perform a weekly inspection of your CNC laser engraver. Check for any loose wiring, overheating components, or unusual sounds. Early detection of potential issues can save you from costly repairs later.

When troubleshooting, it’s essential to have a systematic approach. The Laser Institute of America suggests that operators should refer to the equipment's manual for specific error codes and remedies. For instance, if your engraver is producing uneven cuts, it may be time to recalibrate or replace worn-out components.

Tip: Keep a log of any problems encountered and the troubleshooting steps taken. This not only aids in identifying patterns in equipment failure but also serves as a useful reference for future maintenance.