The Future of Woodworking with the Best Laser Engraver Technology

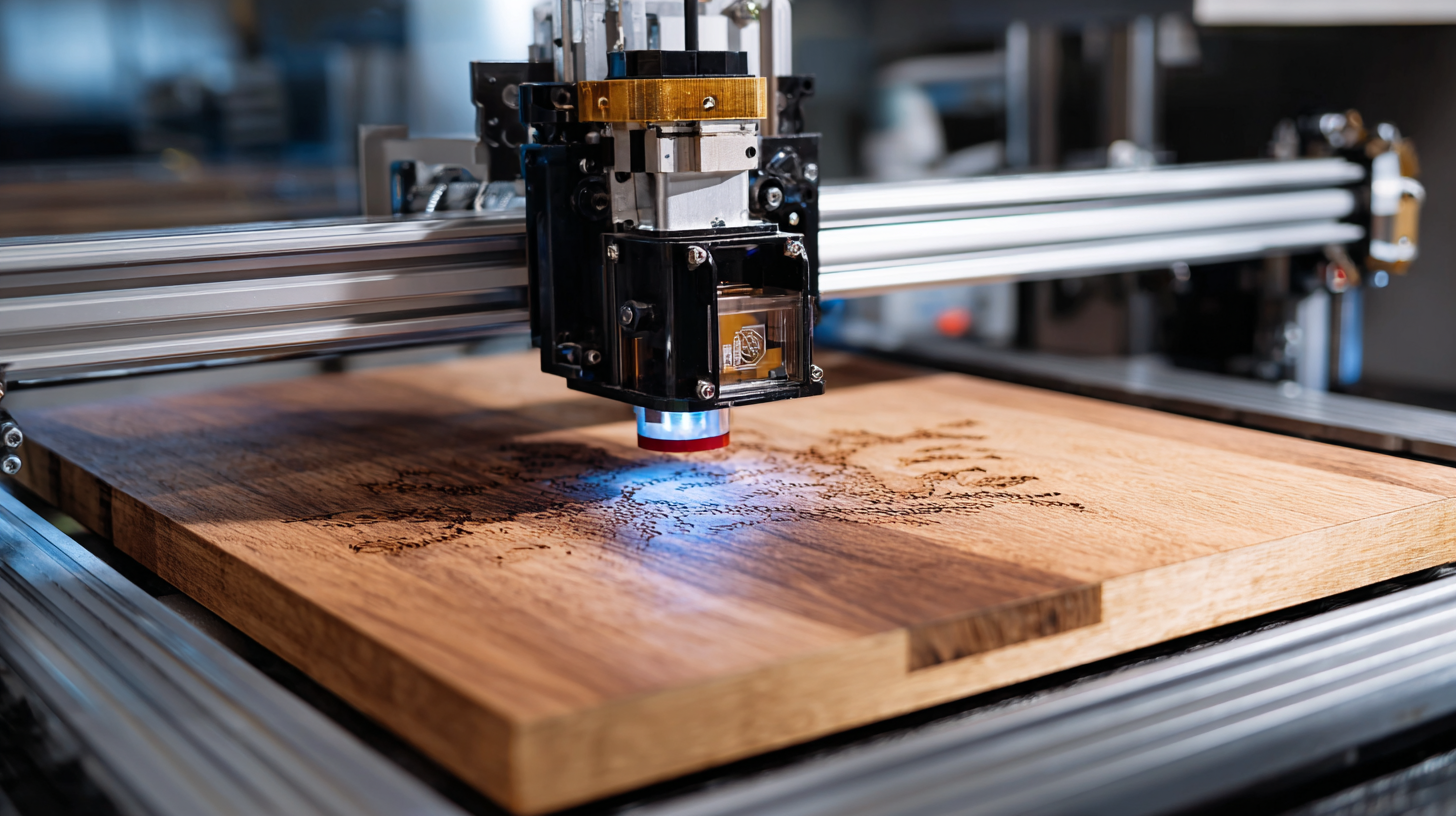

In an era where technology continues to revolutionize traditional crafts, the future of woodworking is becoming increasingly intertwined with advanced laser engraving solutions. The emergence of state-of-the-art laser engravers for wood is transforming how artisans and manufacturers approach their craft, allowing for precise and intricate designs that were once impossible with conventional methods.

As we delve into the potential of these innovative machines, we’ll explore how "实力工厂,中国制造,出口全球" embodies the spirit of advanced manufacturing in China, showcasing how it has become a powerhouse in producing quality laser engravers that cater to global markets.

This integration of high-tech tools not only enhances creativity and efficiency in woodworking but also prepares craftsmen to meet the growing diverse demands of consumers. Join us as we uncover the endless possibilities that lie ahead in the woodworking industry, driven by the best laser engraver technology available today.

The Evolution of Woodworking: Embracing Advanced Laser Engraver Technology

The evolution of woodworking has taken a remarkable turn with the integration of advanced laser engraver technology. Traditionally, woodworkers relied on hand tools and manual techniques to create intricate designs and patterns. However, the advent of laser engraving has revolutionized this process, allowing for precision and efficiency that was previously unattainable. This technology enables craftsmen to produce detailed engravings and cuts with remarkable speed, opening up new horizons for creativity in woodworking projects.

As more artisans embrace laser engravers, they are discovering the potential to push artistic boundaries. The ability to customize designs digitally means that woodworkers can easily create unique pieces that reflect personal styles and themes. Gone are the days when templates and stencils limited creativity; today, intricate designs can be executed with unmatched accuracy. This innovation not only enhances the aesthetic value of wooden items but also caters to the growing demand for personalized gifts and bespoke furniture, making woodworking a more versatile and appealing craft in the modern age.

Understanding Laser Engraving: Key Features for Woodworking Enthusiasts

Laser engraving technology has revolutionized the woodworking industry, offering enthusiasts a powerful tool to enhance their craft. Understanding key features of laser engravers can significantly impact the quality of projects. For instance, the wattage of the laser is crucial; higher wattage allows for deeper cuts and faster processing times, which is essential for intricate designs on various wood types. Additionally, adjustable speed settings enable users to control the precision of their engravings, ensuring that every detail is accurately represented.

Another important feature to consider is the focus capability of the laser. A good laser engraver will offer adjustable focus to accommodate different material thicknesses and types, allowing woodworkers to achieve optimal results tailored to their specific projects. Moreover, software compatibility is vital for ease of use; selecting a system that works seamlessly with design software can streamline the workflow and enhance creativity. As woodworking technology continues to evolve, mastering these features will empower enthusiasts to push the boundaries of their creations while embracing the future of woodworking.

Exploring Different Types of Laser Engravers for Creative Wood Projects

The woodworking industry is experiencing a significant transformation with the integration of laser engraver technology. According to a recent report by Markets and Markets, the global laser engraving market is projected to grow from USD 3.4 billion in 2020 to USD 5.2 billion by 2025, showcasing a compound annual growth rate (CAGR) of 8.7%. This growth is fueled by the increasing demand for personalized and creative wooden products, making it vital for woodworkers to adopt advanced tools.

Laser engravers come in various types, each tailored to specific creative wood projects. CO2 laser engravers are popular for their versatility, suitable for cutting and engraving softwoods and hardwoods alike. Their ability to perform intricate designs makes them a favorite among hobbyists and professionals. On the other hand, fiber laser engravers are becoming increasingly prevalent for those working with metal accents in wood projects, offering fine detailing and high-speed processing. For woodworkers aiming for exceptional quality and precision, diode lasers are a compact and cost-effective choice, perfect for smaller projects or detailed engraving work.

The diverse range of laser engraver types not only enhances the creative possibilities in woodworking but also encourages innovation within the industry. As woodworkers harness the power of these advanced tools, they can push the boundaries of craftsmanship and design, paving the way for a new era of woodworking.

The Future of Woodworking with the Best Laser Engraver Technology

| Laser Type | Power (W) | Max Engraving Speed (mm/s) | Materials Compatible | Price Range (USD) |

|---|---|---|---|---|

| CO2 Laser | 40 - 100 | 400 | Wood, Acrylic, Leather | $500 - $3000 |

| Fiber Laser | 20 - 100 | 600 | Metal, Wood, Plastics | $1000 - $5000 |

| Diode Laser | 1 - 5 | 200 | Wood, Leather, Cardstock | $200 - $800 |

| YAG Laser | 10 - 50 | 300 | Metal, Wood, Ceramics | $1500 - $7000 |

Innovative Applications of Laser Engraving in Modern Woodworking

The innovative applications of laser engraving technology have revolutionized modern woodworking, enabling artisans to achieve precision and creativity that were previously unattainable. Laser engravers offer unparalleled detail, allowing woodworking professionals to create intricate designs, patterns, and textures with ease. This technology not only enhances the aesthetic appeal of wooden pieces but also significantly reduces the time and effort involved in traditional engraving methods. From bespoke furniture to personalized gifts, the possibilities are endless, enabling woodworkers to expand their portfolios and cater to a broader audience.

Moreover, laser engravers facilitate customization like never before. Artisans can rapidly prototype designs, make adjustments, and execute complex patterns that would be labor-intensive using traditional tools. This flexibility encourages innovation, as woodworkers can experiment with various materials and techniques, further pushing the boundaries of creative expression. As the demand for unique and personalized products continues to grow, integrating laser engraving into woodworking practices will undoubtedly become a crucial aspect of staying competitive in the industry.

Future Trends: How Laser Engraving Will Shape the Craftsmanship Landscape

As we delve into the future of woodworking, laser engraving technology is set to revolutionize craftsmanship in unprecedented ways. Traditional woodworking has always been about meticulous handwork and skillful techniques, but with the advent of advanced laser engravers, artisans can now achieve precision that was previously unimaginable. This shift means that intricate designs that may have taken hours or even days to carve manually can now be accomplished in a fraction of the time, allowing craftsmen to explore new creative horizons and produce more intricate work.

Moreover, the accessibility of laser engraving technology is democratizing the craft, enabling hobbyists and small-scale makers to compete with larger companies. With user-friendly software and affordable machines, anyone with a passion for woodworking can experiment with personalized designs, creating custom products that resonate with customers on a deeper level. As this technology continues to evolve, we can expect to see a surge of innovative products that blend traditional woodworking techniques with modern laser capabilities, ensuring that craftsmanship remains an art form while also embracing the efficiency of contemporary methods.

The Future of Laser Engraving in Woodworking

This chart illustrates the anticipated growth in laser engraving technology's impact on various woodworking sectors over the next five years. As advancements in technology continue, more craftsmen are expected to adopt laser engraving for precision and creativity.