Exploring Innovative Examples of CNC Industrial Machine Applications

As the manufacturing landscape continues to evolve, the adoption of CNC industrial machines has become increasingly integral to driving efficiency and innovation. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $117.45 billion by 2026, growing at a CAGR of 6.1% from 2021. This surge reflects the growing demand for precision manufacturing across various industries, including automotive, aerospace, and electronics. CNC industrial machines not only enhance production capabilities but also improve product quality and reduce waste, aligning with modern sustainability goals.

In this blog, we will explore innovative examples of CNC industrial machine applications that illustrate how these technologies are revolutionizing the manufacturing process, showcasing their versatility and effectiveness in meeting contemporary production challenges.

Innovative CNC Applications in Aerospace Engineering

The aerospace engineering sector is rapidly adopting innovative CNC (Computer Numerical Control) applications to enhance manufacturing capabilities. According to the latest industry analysis, the global CNC machine market is projected to expand from $101.22 billion in 2025 to $195.59 billion by 2032, reflecting an impressive CAGR of 9.9%. Such growth underscores the increasing reliance on CNC technology for precision tasks, which are critical in aerospace applications where accuracy and reliability are paramount.

A significant area of development is in the use of CNC machines for intricate component manufacturing in aircraft and spacecraft production. For instance, advanced CNC machining offers enhanced capabilities for fabricating lightweight yet durable parts, which are essential for improving fuel efficiency and performance in aerospace vehicles. The integration of CAD (Computer-Aided Design) software with CNC technology facilitates the creation of sophisticated 3D models, enabling engineers to design and produce high-precision parts with unprecedented efficiency. As the industry evolves, these innovative CNC applications will likely play a critical role in shaping the future of aerospace engineering, setting new standards in quality and performance.

Transforming Automotive Manufacturing with CNC Technology

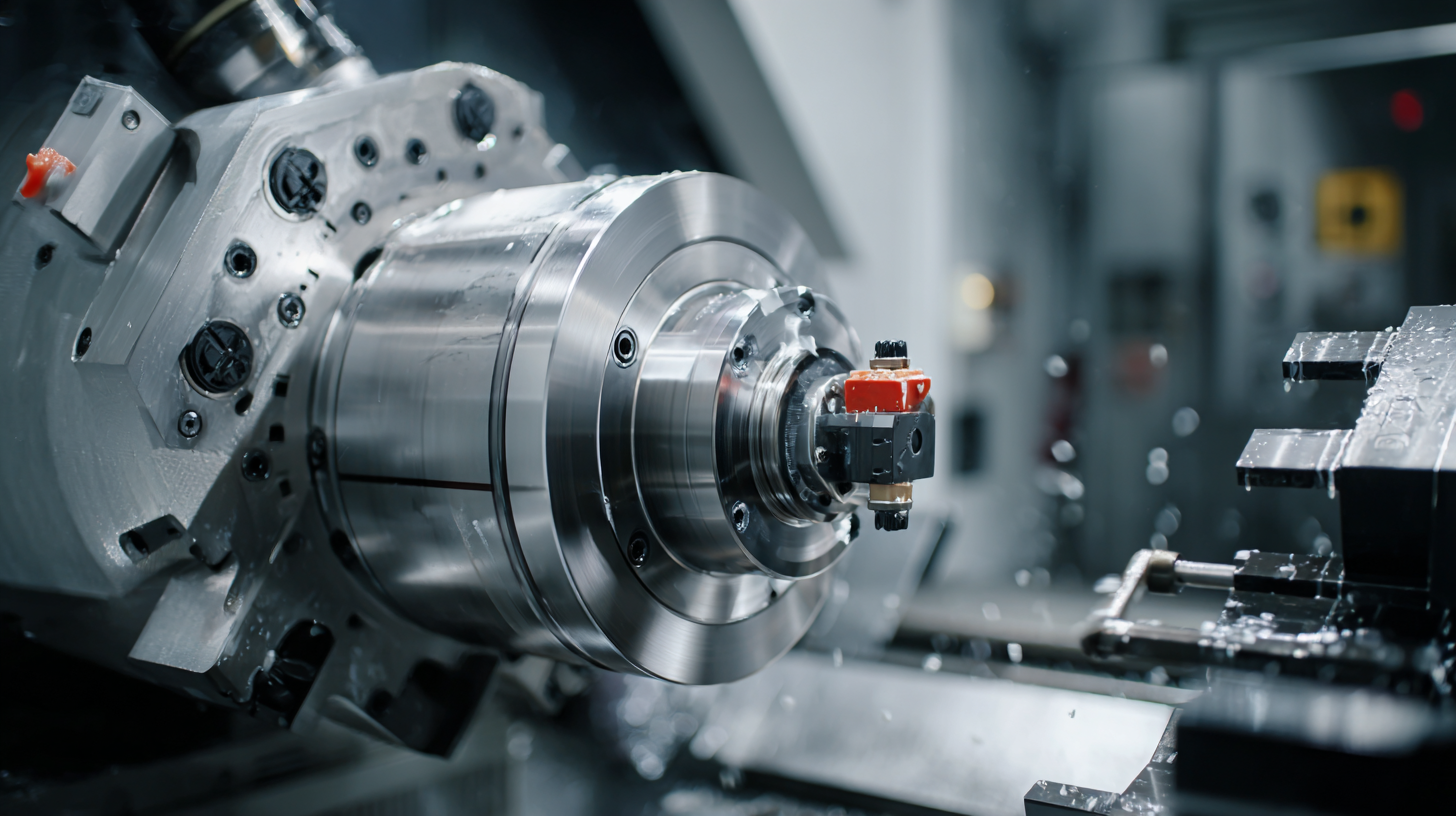

The automotive manufacturing industry is undergoing a significant transformation, largely driven by advancements in CNC (Computer Numerical Control) technology. As manufacturers increasingly adopt CNC machines, they are realizing the benefits of enhanced efficiency, precision, and automation. This revolution in manufacturing processes not only reduces production time but also improves the quality of end-use parts, making it an invaluable asset for automotive companies.

The growing demand for automation is expected to further accelerate the market for CNC technology. With the global CNC controller market projected to reach $7.2 billion by 2033, the impact of CNC machines on automotive manufacturing cannot be overstated. Innovations in CNC machining technology are allowing manufacturers to optimize milling parameters and streamline production workflows. As a result, businesses are not only meeting the ever-increasing consumer expectations but also paving the way for sustainable practices in the industry. The future looks bright for automotive manufacturing as it embraces the transformative power of CNC technology.

Innovative CNC Machine Applications in Automotive Manufacturing

CNC in the Production of Custom Medical Devices

CNC technology has revolutionized the production of custom medical devices, allowing for unparalleled precision and customization. With the ability to create complex geometries and intricate designs, CNC machines enable manufacturers to produce tailored solutions that meet specific patient needs. From surgical instruments to orthopedic implants, the potential applications are vast and critical in enhancing patient care.

Tip: When designing custom medical devices, it’s essential to collaborate closely with the healthcare professionals who will use them. Gathering insights from end-users can provide valuable feedback that informs design adjustments, ensuring both functionality and comfort.

Moreover, the integration of computer-aided design (CAD) with CNC machining streamlines the entire process, reducing lead times and minimizing errors. This synergy not only enhances efficiency but also allows for rapid prototyping and testing of innovative designs, which is crucial in the fast-paced medical field.

Tip: Investing in quality materials is vital when producing medical devices. Choosing biocompatible materials not only ensures patient safety but can also improve the longevity and performance of the devices in clinical applications.

Exploring Innovative Examples of CNC Industrial Machine Applications - CNC in the Production of Custom Medical Devices

| Application Area | CNC Technology Used | Material | Production Volume | Customization Level |

|---|---|---|---|---|

| Prosthetic Devices | CNC Milling | Titanium | Low to Medium | High |

| Dental Implants | CNC Turning | Zirconia | Medium | Moderate |

| Orthopedic Devices | CNC Router | Polymer | High | Very High |

| Surgical Instruments | CNC Laser Cutting | Stainless Steel | Medium to High | High |

| Custom Implants | CNC 3D Printing | Bio-Compatible Polymers | Low | Very High |

Exploring CNC Techniques in Artistic Sculpting and Design

In the realm of artistic sculpting and design, CNC techniques are redefining the boundaries of creativity. Recent works, such as the experimental sculpture "Pump" by Professor Chao in Taiwan, showcase how CNC technology can fuse art with cutting-edge innovation. This piece not only captures the attention of audiences but also earned accolades at the London International Creative Competition (LICC). Chao’s exploration of information fragmentation and recombination through meticulous CNC processes highlights the significant role technology plays in contemporary artistry.

Moreover, advancements in robotic systems have further revolutionized the field of sculpting. The partnership between robotics and design specialists has led to the creation of sophisticated tools tailored for ice sculpting. This new system integrates various high-precision attachments, enabling artists to execute their visions with enhanced efficiency and accuracy. As CNC technology continues to evolve, it opens a new chapter for artists, allowing them to push the limits of traditional sculpting and embrace innovative approaches that blend artistry with industrial techniques.

Advancements in CNC for Sustainable Woodworking Solutions

As the woodworking industry increasingly embraces sustainable practices, advancements in CNC (Computer Numerical Control) technology are at the forefront of this transformation. The global woodworking machinery market is projected to grow significantly, with forecasts estimating it will rise from $5.23 billion in 2025 to $7.88 billion by 2032, achieving a compound annual growth rate of 6.0%. This growth highlights the urgent need for innovative solutions that not only enhance efficiency but also minimize environmental impact.

CNC machines are revolutionizing the way wood is processed, allowing for intricate designs and precise cuts while reducing waste. With the integration of advanced software and automation, these machines enable woodworkers to produce complex components with minimal manual labor and a higher degree of consistency. Furthermore, CNC technology supports the use of sustainably sourced materials, ensuring that the woodworking industry can meet the rising demand for eco-friendly products. As we continue to explore these innovations, it becomes clear that the future of woodworking is not only about craftsmanship but also about creating sustainable solutions that resonate with environmentally conscious consumers.