Why Invest in CNC Industrial Machines for Your Manufacturing Needs?

Investing in CNC industrial machines has become a critical factor for manufacturers aiming to enhance productivity and maintain competitive advantages in today's fast-paced market. According to a report from Market Research Future, the global CNC machine market is anticipated to reach approximately $100 billion by 2026, growing at a CAGR of around 6% during the forecast period. This growth underscores the increasing reliance on precision engineering and automation in manufacturing processes.

The integration of CNC industrial machines not only reduces human error but also streamlines production cycles, enabling businesses to respond swiftly to customer demands while optimizing resource allocation. A study from Grand View Research highlights that the automation of manufacturing processes through advanced CNC technologies can increase efficiency by up to 30%, leading to significant cost savings and higher output quality. As industries continuously seek to innovate and drive operational excellence, the adoption of CNC industrial machines stands out as a strategic investment that can propel manufacturing capabilities into the future.

The Role of CNC Machines in Modern Manufacturing Processes

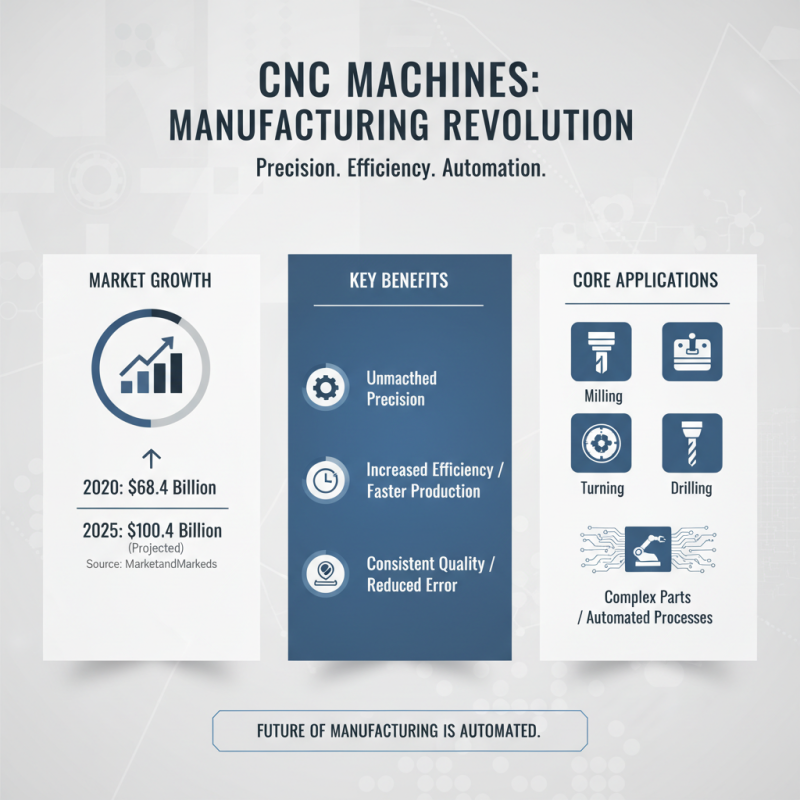

CNC (Computer Numerical Control) machines have revolutionized modern manufacturing, providing a level of precision and efficiency that traditional methods simply cannot match. According to a report by MarketsandMarkets, the CNC machine market is projected to grow from $68.4 billion in 2020 to $100.4 billion by 2025, reflecting the increasing reliance on automation in manufacturing processes. These machines enable manufacturers to produce complex parts with intricate designs while minimizing human error. The automation of milling, turning, and drilling operations not only speeds up production but also ensures consistent quality across all manufactured items.

One of the key advantages of CNC machines is their ability to operate continuously, leading to improved productivity. For instance, a study from the National Institute of Standards and Technology (NIST) found that CNC machines can operate at speeds of up to 1000 inches per minute, dramatically reducing cycle times. This efficiency allows manufacturers to meet tight deadlines and respond flexibly to customer demands.

**Tip:** When investing in CNC machines, consider your specific manufacturing needs. Assess the types of materials you use and the complexity of the parts you produce to choose the appropriate machine type and features.

Furthermore, CNC technology facilitates innovative design capabilities. The integration of CAD (Computer-Aided Design) software with CNC machines allows for seamless transition from design to production. As reported by SME Media, this synergy can cut the time from concept to market by up to 75%. By embracing CNC technologies, manufacturers are not only optimizing their current processes but also positioning themselves to innovate in their product offerings.

**Tip:** Regular maintenance of CNC machines is crucial. Schedule routine check-ups and training for operators to ensure that the machines run smoothly and efficiently.

Key Advantages of Investing in CNC Industrial Machines

Investing in CNC (Computer Numerical Control) industrial machines offers significant advantages for manufacturing businesses looking to enhance their production capabilities. One of the key benefits is the precision and consistency these machines provide. According to a report by MarketsandMarkets, the CNC machine market is projected to reach $100 billion by 2025, indicating a growing recognition of the technology's importance in manufacturing. These machines can operate with tolerances as tight as ±0.001 inches, which is crucial for industries where precision is paramount, such as aerospace and medical devices.

Another compelling advantage is the efficiency and productivity gains that CNC machines deliver. With the ability to automate complex machining processes, CNC machines can produce components at a much faster rate than traditional manual methods. A study from the National Institute of Standards and Technology (NIST) highlights that the adoption of CNC technology can lead to productivity improvements of up to 30%. This not only reduces production time but also optimizes resource allocation, allowing manufacturers to allocate labor to more strategic tasks, ultimately enhancing the bottom line. As manufacturers strive to improve operational efficiency and reduce error rates, investing in CNC industrial machines has become increasingly vital in staying competitive in the modern manufacturing landscape.

Comparative Analysis: CNC Machines vs. Traditional Manufacturing Tools

The transition from traditional manufacturing tools to CNC (Computer Numerical Control) machines has fundamentally transformed the manufacturing landscape. According to a recent industry report by McKinsey, businesses that adopted CNC machines noted a productivity increase of up to 30%. This significant enhancement is attributed to the precision and automation offered by CNC technology, which minimizes human error and allows for complex designs to be executed with ease.

In contrast, traditional manufacturing methods often rely on manual input and oversight, leading to inconsistencies and longer production times.

Furthermore, a study conducted by the International Federation of Robotics highlights that CNC machines can reduce material waste by approximately 25% compared to conventional tools. This efficiency not only impacts profit margins positively but also contributes to more sustainable manufacturing practices. Traditional manufacturing tools, often limited by manual capabilities, tend to generate more scrap and necessitate additional time for adjustments and corrections.

As manufacturers seek to improve their operational efficiency and reduce costs, the comparative benefits of CNC machines become more evident, emphasizing their essential role in modern manufacturing.

Cost-Benefit Evaluation of CNC Machine Investments

When considering the investment in CNC industrial machines, a thorough cost-benefit evaluation is vital to determine the potential return on investment (ROI). One of the main advantages of CNC machines is their ability to increase precision in manufacturing processes, which leads to reduced material waste and enhanced product quality. This precision translates to lower operational costs over time, as fewer errors mean less rework and scrap. Additionally, the automation capabilities of CNC machines enable manufacturers to optimize production schedules, ultimately resulting in improved throughput and efficiency.

Moreover, while the upfront costs of CNC machines can be significant, the long-term savings often outweigh these initial expenses. By increasing automation, businesses can reduce labor costs and minimize human error, leading to faster turnaround times and stronger customer satisfaction. The scalability of CNC technology also allows manufacturers to adapt to changing market demands without incurring substantial additional costs. This adaptability not only protects existing investments but also positions companies for growth in competitive landscapes, making CNC machine investments worthwhile over time.

Future Trends in CNC Technology and Its Impact on Manufacturing

The landscape of manufacturing is undergoing a significant transformation driven by advancements in CNC (Computer Numerical Control) technology. Future trends suggest that as industries adopt more sophisticated CNC machines, they will benefit from enhanced precision and efficiency. Emerging technologies such as artificial intelligence and machine learning are being integrated into CNC systems, allowing for smarter operations that optimize machining processes. These innovations enable manufacturers to reduce waste, improve production speeds, and ultimately lower costs, setting the stage for a more sustainable manufacturing environment.

Additionally, the rise of collaborative robots, or cobots, in conjunction with CNC machines is reshaping workforce dynamics on the shop floor. These robots can work alongside human operators, taking over repetitive tasks and allowing skilled workers to focus on more complex operations. The integration of IoT (Internet of Things) capabilities into CNC machinery is also anticipated to enable real-time data analysis, enhancing predictive maintenance and reducing downtime. As organizations embrace these technological advancements, they will be better positioned to respond to market demands and customize their offerings, moving towards a future where flexibility and responsiveness are key competitive advantages.

Why Invest in CNC Industrial Machines for Your Manufacturing Needs?

| Feature | Description | Impact on Manufacturing |

|---|---|---|

| Precision Engineering | CNC machines can achieve high levels of precision, allowing for intricate designs and tighter tolerances. | Reduces material wastage and enhances product quality. |

| Automation | CNC machines can be automated to perform repetitive tasks without human intervention. | Increases efficiency and lowers labor costs. |

| Versatility | CNC machines can work with a variety of materials, such as metal, wood, and plastics. | Allows manufacturers to diversify their product offerings. |

| Cost-Effectiveness | Although initial investment is high, the long-term operational savings are significant. | Improves profit margins over time due to reduced production costs. |

| Future Trends | Integrating AI and machine learning with CNC technology. | Enhances predictive maintenance, optimizing production schedules. |

Related Posts

-

What is a CNC Industrial Machine and How It Transforms Manufacturing

-

Unveiling the Technical Specifications of the Best CNC Machine for Precision Engineering

-

Unlocking Precision: How CNC Industrial Machines Revolutionize Manufacturing Efficiency

-

2025 How to Choose the Best CNC Machine for Your Manufacturing Needs: A Data-Driven Guide

-

7 Amazing Features of the Best 3D CNC Machine You Need to Know

-

Unlocking the Future of Best CNC Machine Industrial in 2025 Strategies for Global Buyers