5 Key Benefits of Investing in Wood CNC Machines for Global Manufacturers

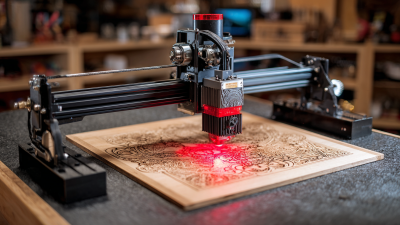

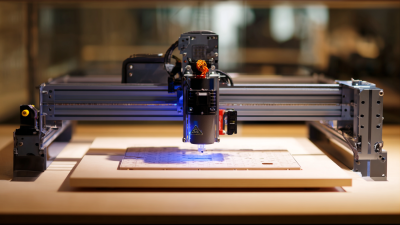

In today's competitive manufacturing landscape, global manufacturers are increasingly turning to advanced technologies to enhance productivity and efficiency. One such technology that has gained significant traction is the wood CNC machine, which allows for precision cutting, shaping, and engraving of wooden materials. According to a report by Grand View Research, the global CNC woodworking machine market was valued at approximately $2.70 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2028. This growing demand highlights the critical role that wood CNC machines play in modern manufacturing processes. By investing in these machines, manufacturers not only benefit from increased accuracy and reduced waste but also gain the ability to produce complex designs that enhance product offerings and meet consumer expectations. As we explore the five key benefits of investing in wood CNC machines, it becomes clear how these innovations can drive operational success and foster growth in the manufacturing sector.

Advantages of Precision and Efficiency in Wood CNC Production

Investing in wood CNC machines offers global manufacturers unparalleled precision and efficiency in production processes, revolutionizing how wood products are crafted. According to a recent industry report by Ceresana, the CNC machine market is expected to surpass USD 100 billion by 2028, underscoring the growing demand for automation in woodworking. Precision is a significant advantage, as CNC machines can achieve tolerances of up to 0.01 mm, resulting in products that meet exact specifications with minimal waste. This level of accuracy not only enhances product quality but also reduces material costs, thereby improving profitability.

Efficiency is another critical benefit of wood CNC machines. A study published in the Journal of Manufacturing Science and Engineering highlights that manufacturers adopting CNC technology can increase productivity by 30% or more compared to traditional methods. This efficiency gains arise from reduced setup times, faster cutting speeds, and the ability to run machines continuously with minimal human intervention.

Tips for manufacturers considering this investment include evaluating their current production processes to identify bottlenecks where CNC technology could enhance efficiency. Additionally, integrating CNC machines with advanced software can streamline operations further, allowing for real-time monitoring and adjustments to maintain optimal performance and reduce downtime. Engaging with providers offering comprehensive training can also ensure a smoother transition and maximize the benefits of the new technology.

Cost Savings: Long-Term Financial Benefits of Wood CNC Investments

Investing in wood CNC machines offers significant long-term financial benefits for global manufacturers, particularly in an era where economic landscapes are ever-changing. These advanced machines not only enhance precision and productivity but also reduce waste and labor costs. By automating various processes, manufacturers can streamline their operations, which translates into lower operational costs over time. This cost efficiency makes CNC machines an attractive option for businesses looking to maintain competitive pricing while maximizing output.

Moreover, as countries like China advance in innovation within their industries, global manufacturers must adapt to remain relevant. Investing in wood CNC technology positions manufacturers to leverage these innovations, ensuring they can meet the rising demands for quality and efficiency. With the right equipment, companies can respond swiftly to market fluctuations, turning potential financial hurdles into opportunities for growth. Thus, embracing wood CNC machines becomes not just a modernization effort but a strategic move towards securing financial stability and competitiveness in a rapidly evolving market.

5 Key Benefits of Investing in Wood CNC Machines for Global Manufacturers

Enhancing Design Flexibility and Customization with CNC Technology

In today's competitive manufacturing landscape, wood CNC machines offer global manufacturers an unparalleled advantage in design flexibility and customization. Utilizing advanced CNC technology allows manufacturers to create intricate and detailed designs that were previously limited by traditional woodworking methods. This capability not only enhances product aesthetics but also caters to the unique preferences of consumers, making it easier to meet diverse market demands.

Tip: Consider investing in a CNC machine with a versatile software package that includes design templates and customization options. This can significantly streamline the design process and reduce turnaround times, allowing you to respond swiftly to customer requests.

Moreover, the precision and repeatability of CNC machines enable manufacturers to produce custom components with consistent quality. Whether crafting bespoke furniture or intricate architectural details, the ability to easily adjust designs ensures that even the most complex ideas can be realized without sacrificing efficiency.

Tip: Regular training sessions for your design and production teams can further enhance creativity and innovation. By staying up-to-date with the latest software updates and design trends, your team can continuously improve your offerings and appeal to a wider audience.

Sustainability and Eco-Friendly Practices in Wood Manufacturing

As the global manufacturing industry continues to evolve, sustainability and eco-friendly practices are becoming increasingly imperative. Investing in wood CNC machines not only enhances precision and efficiency but also aligns with the growing emphasis on sustainable production methods. These machines optimize material usage by minimizing waste, allowing manufacturers to source raw materials more responsibly and contribute positively to forest conservation efforts.

Tips for Implementing Eco-Friendly Practices:

1. **Maximize Material Efficiency**: Utilize CNC programming to design layouts that reduce excess cutting waste, ensuring that every inch of wood is utilized effectively. This not only conserves resources but also results in cost savings.

2. **Choose Sustainable Wood Sources**: Prioritize suppliers who practice sustainable forestry. By opting for certified materials such as FSC (Forest Stewardship Council) certified wood, manufacturers can ensure their products support environmentally responsible practices.

3. **Implement Energy-Efficient Operations**: Invest in energy-efficient wood CNC machines that consume less power and reduce the overall carbon footprint of the manufacturing process. Regular maintenance and upgrades can also enhance efficiency and prolong machine life.

By adopting these eco-friendly habits, manufacturers can lead by example in the pursuit of a sustainable future while also reaping the benefits of advanced technology in wood production.

Competitive Edge: How CNC Machines Elevate Global Market Positioning

The rise of CNC machines in the global manufacturing landscape has profoundly influenced market positioning and competitiveness. With the global CNC machines market projected to expand at a CAGR of 9.8%, reaching unprecedented levels by 2032, manufacturers are increasingly embracing this technology to enhance efficiency and precision. This integration not only streamlines production processes but also significantly elevates a company's ability to deliver customized solutions, setting them apart in a crowded marketplace.

As competition intensifies, especially in the Asia Pacific region where machine tools are experiencing robust growth, manufacturers are keen to capitalize on the advantages offered by wood CNC machines. The global machining centers market, valued at USD 29.17 billion in 2018 and expected to soar to USD 60.13 billion by 2032, underscores the growing importance of advanced machinery in maintaining a competitive edge. Companies leveraging intelligent manufacturing processes can rapidly respond to market demands and optimize their operational capabilities, thereby solidifying their positioning in the ever-evolving global arena.

5 Key Benefits of Investing in Wood CNC Machines for Global Manufacturers

| Benefit | Description | Impact on Market Positioning |

|---|---|---|

| Increased Production Efficiency | CNC machines automate cutting, reducing labor time and minimizing errors. | Allows manufacturers to meet higher demand with faster turnaround times. |

| Enhanced Design Flexibility | Easily modify designs and prototype new products without additional costs. | Helps companies stay competitive with innovative product offerings. |

| Improved Product Quality | Precision machining results in consistent and high-quality products. | Strengthens brand reputation and increases customer satisfaction. |

| Cost Savings | Reduction in waste material and labor costs due to higher accuracy. | Enables competitive pricing strategies, enhancing market presence. |

| Sustainability | Uses advanced technology to minimize environmental impact. | Attracts eco-conscious consumers, improving market share. |

Related Posts

-

Top Strategies for Sourcing the Best CNC Wood Carving Machines Worldwide

-

Unlocking Creativity with CNC Wood Carving Machines and Their Unique Advantages

-

10 Reasons the Best CNC Laser Engraver Will Transform Your Business

-

The Future of Precision Crafting with Best CNC Laser Engravers

-

Maximize Your Investment with Top After Sales Support and Repair Cost Tips for Best CNC Router Table

-

China's Intelligent Manufacturing Revolutionizes the Global Market for Best CNC Router Machines