Maximize Your Investment with Top After Sales Support and Repair Cost Tips for Best CNC Router Table

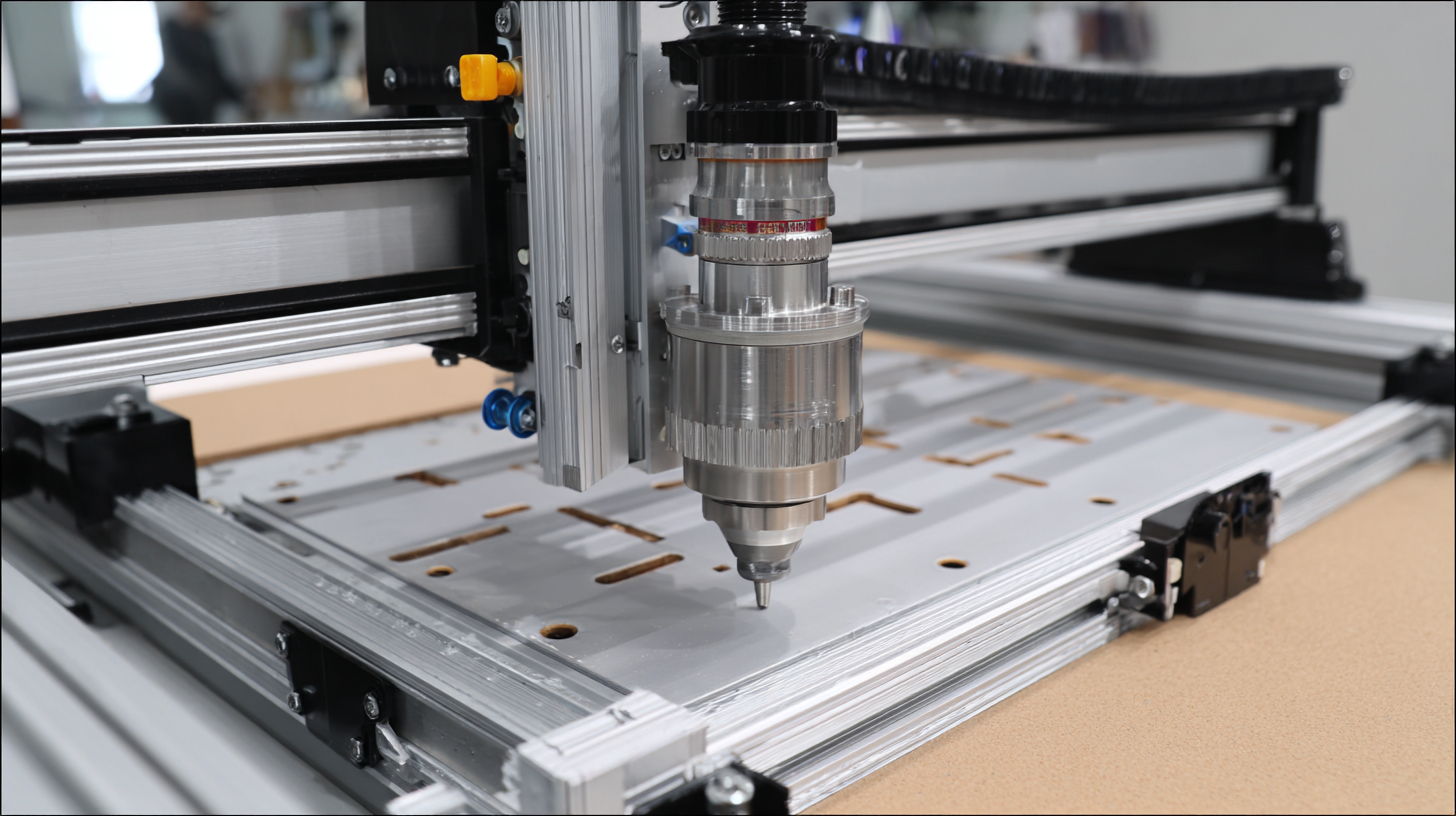

In today's fast-paced manufacturing environment, investing in a high-quality CNC router table is just the beginning of a successful venture. While selecting the right machine is crucial, it is equally important to secure robust after-sales support and manage repair costs effectively to maximize your investment. Understanding how to navigate the complexities of post-purchase services can save you time and money, ensuring that your CNC router table operates at peak performance.

This blog will provide essential tips on optimizing after-sales support and managing repair expenses, helping you to protect your investment and maintain the efficiency of your operations. Join us as we explore strategies that can create a seamless experience for users and boost the longevity of your CNC router table, ultimately paving the way for a successful future in your woodworking or manufacturing projects.

Key Factors to Consider for After Sales Support When Choosing a CNC Router Table

When choosing a CNC router table, after sales support is a crucial factor that can significantly influence your investment's longevity and efficiency. One of the key aspects to consider is the availability of technical support. Look for manufacturers that offer robust customer service options, including online chat, email, and phone support. Quick access to knowledgeable professionals can help you tackle issues promptly and minimize downtime.

Another critical factor is the warranty and repair services offered by the manufacturer. Ensure that you understand the terms of the warranty and what repairs are covered. A strong warranty can save you money in the long run, making it essential to select a CNC router table with favorable coverage. Additionally, inquire about the availability of replacement parts and how easily they can be sourced if needed.

Lastly, consider the maintenance tips provided by the manufacturer. Regular maintenance can prevent costly repairs down the line. Look for models that come with comprehensive user guides and support resources that outline best practices for keeping your CNC router table in optimal condition. Investing time in understanding and utilizing these tips can greatly enhance your machine's performance and lifespan.

Understanding Repair Costs and Their Impact on Your CNC Router Investment

When investing in a CNC router table, understanding repair costs is essential for maximizing your overall return on investment. Repair costs can significantly affect your budget, so being proactive about maintenance and support can help mitigate these expenses. Regular check-ups and timely repairs not only extend the life of your equipment but also ensure that it operates at peak efficiency.

One effective tip is to establish a preventive maintenance schedule. By routinely inspecting and servicing your CNC router, you can identify potential issues before they escalate into costly repairs. This approach not only minimizes downtime but also enhances the reliability of your equipment, ensuring that your production process remains uninterrupted.

Additionally, consider investing in comprehensive after-sales support from your manufacturer. Quality technical support can help you troubleshoot minor issues before they turn into significant problems. Furthermore, some manufacturers offer training for your staff, equipping them with the knowledge to handle basic maintenance and repairs, further reducing your long-term costs.

Maximize Your Investment with Top After Sales Support and Repair Cost Tips for Best CNC Router Table

| CNC Router Model | Average Initial Cost ($) | Annual Maintenance Cost ($) | Repair Cost per Incident ($) | Average Downtime (Days) | Support Availability (Hours/Week) |

|---|---|---|---|---|---|

| Model A | $3,500 | $500 | $150 | 3 | 40 |

| Model B | $5,000 | $700 | $200 | 2 | 24 |

| Model C | $4,200 | $600 | $180 | 4 | 36 |

| Model D | $6,000 | $800 | $220 | 1 | 48 |

Maximizing Productivity Through Efficient Maintenance Strategies for CNC Router Tables

Maximizing productivity in your CNC router table operations hinges significantly on effective maintenance strategies.

Regular maintenance not only extends the life of your equipment but also minimizes downtime, which can be detrimental to your workflow. Establishing a routine maintenance schedule that includes cleaning, lubrication, and inspection of key components can prevent small issues from escalating into major problems. Implementing a checklist can be an invaluable tool, ensuring that no critical maintenance task is overlooked and keeping your CNC router in peak condition.

Investing in quality after-sales support can further enhance the performance of your CNC router table. This means not only having access to replacement parts but also employing skilled technicians who can provide timely repairs and consultations.

Building a strong relationship with your suppliers ensures that you receive the necessary support, including tips on effective usage and troubleshooting common issues.

When you combine strong maintenance strategies with excellent after-sales care, you position your CNC router table for optimal performance, ultimately driving productivity to new heights.

Top Tips for Selecting a Reliable Manufacturer for Your CNC Router Needs

When selecting a reliable manufacturer for your CNC router needs, it’s crucial to consider their reputation and track record in the industry. Researching customer reviews and testimonials can provide insight into the experiences of other users. Look for manufacturers who have established themselves as leaders and are known for their exceptional product quality. Engaging with online forums or industry-specific communities can also yield valuable feedback and recommendations, helping you make a more informed decision.

Another key aspect is the manufacturer’s after-sales support. High-quality CNC routers require ongoing maintenance and occasional repairs. A dependable manufacturer should not only provide a comprehensive warranty but also offer robust customer service to assist you post-purchase. Inquire about the availability of spare parts and how quickly they can be delivered. A responsive support team can significantly reduce downtime and enhance your overall investment, ensuring that your CNC router remains operational for years to come.

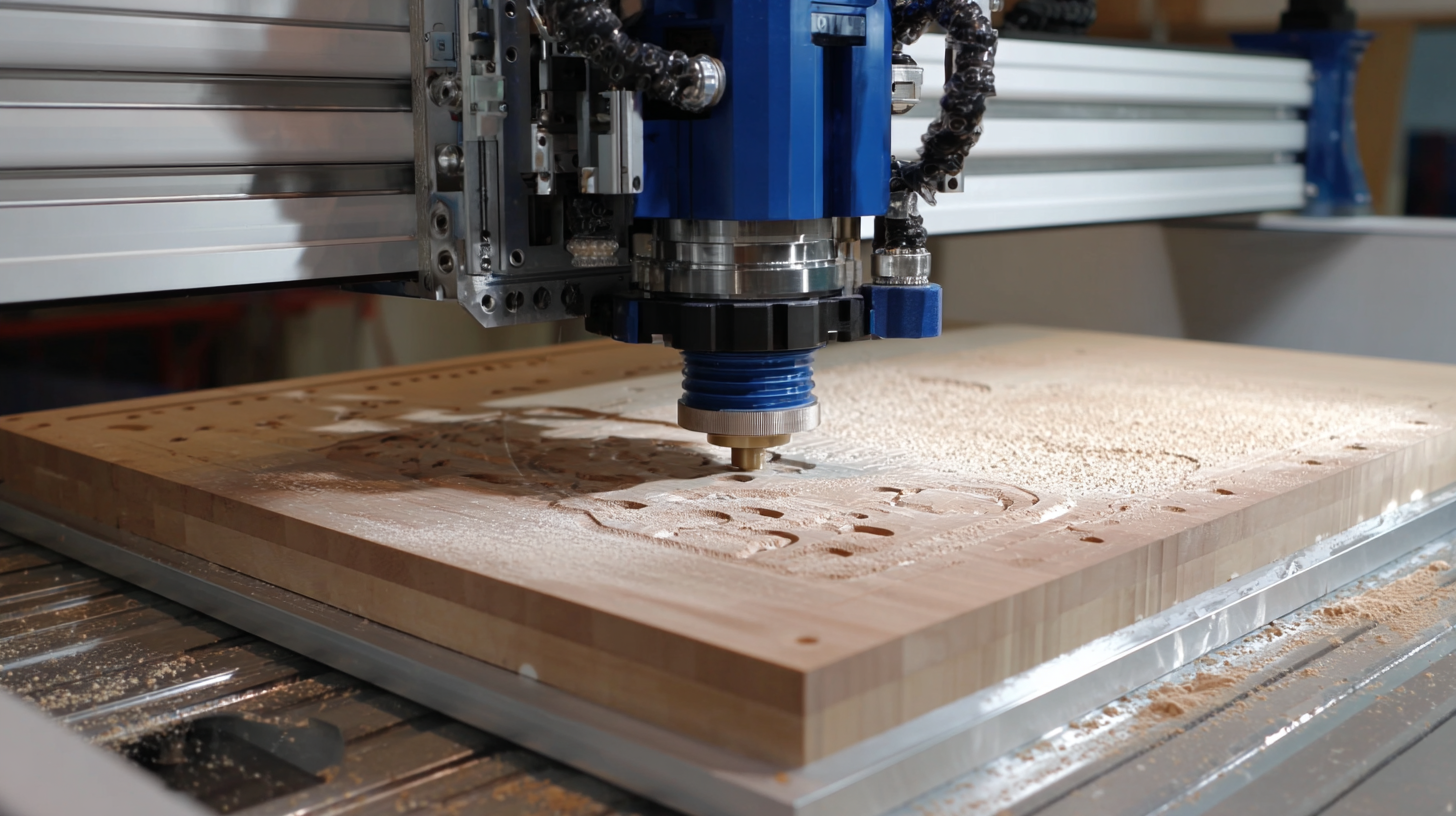

Maximize Your Investment: After Sales Support and Repair Costs for CNC Router Tables

This chart illustrates the average after sales support and repair costs associated with CNC router tables based on various factors. It highlights the importance of selecting a reliable manufacturer to minimize long-term expenses.

How Proactive Support Can Enhance Your CNC Router's Performance Over Time

Proactive support plays a crucial role in enhancing the performance of CNC router tables over time. Research from the Association for Manufacturing Technology indicates that machines equipped with comprehensive after-sales support can experience up to a 30% increase in productivity. Regular maintenance and timely repairs not only prevent downtime but also ensure that the CNC router operates at optimal efficiency. For instance, a study conducted by TWI Ltd. found that machines with preventive maintenance programs have a failure rate reduced by approximately 25%, resulting in significant cost savings in repairs and lost production.

Moreover, investing in after-sales support is a smart financial decision for manufacturers. The Friedrich-Alexander-Universität Erlangen-Nürnberg reported that companies leveraging strategic support services benefit from a 15% reduction in operational costs. By utilizing real-time monitoring and analytics, operators can identify potential issues before they escalate into significant problems. This proactive approach allows for smoother production processes, enhances product quality, and ultimately leads to customer satisfaction. Adequate after-sales support transforms CNC routers from mere machines into reliable partners in manufacturing, ensuring they remain competitive in an increasingly demanding market.