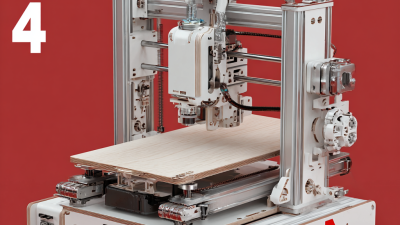

How to Optimize Your CNC Router Machine for Maximum Efficiency and Precision

In today's CNC router machine manufacturing landscape, optimizing the performance is essential for enhancing both efficiency and precision. According to a report by Grand View Research, the global CNC machining market is projected to reach $100 billion by 2025, driven by the increasing demand for custom and high-quality components across various industries. However, many manufacturers still struggle with maximizing the capabilities of their CNC router machines. Factors such as improper setup, inadequate maintenance, and lack of knowledge on best practices can significantly hinder production output and accuracy. As companies strive for competitive advantage in an ever-evolving market, implementing effective optimization strategies is critical not only for improving workflow but also for ensuring long-term profitability and sustainability. This blog will explore actionable steps to help you enhance the efficiency and precision of your CNC router machine, making it a vital tool in your production arsenal.

Understanding the Importance of CNC Router Optimization for Operational Efficiency

Optimizing your CNC router is essential for enhancing operational efficiency and achieving high precision in your projects. When machines are finely tuned, they not only perform better but also extend their lifespan, saving you both time and money. Understanding the importance of CNC router optimization can unlock improved productivity and ensure that your outputs meet the highest quality standards.

Optimizing your CNC router is essential for enhancing operational efficiency and achieving high precision in your projects. When machines are finely tuned, they not only perform better but also extend their lifespan, saving you both time and money. Understanding the importance of CNC router optimization can unlock improved productivity and ensure that your outputs meet the highest quality standards.

One of the key tips for optimizing your CNC router is to regularly maintain and clean your equipment. Dust and debris can accumulate and affect the machine's performance, leading to inaccuracies in cutting. Implementing a routine maintenance schedule, including checking the alignment and calibration of your router, is crucial. Additionally, ensure that the tooling you use is appropriate for the materials you work with; this can significantly improve cut quality and reduce wear on the machine.

Another vital aspect is software optimization. Utilize the latest software updates and ensure that your cutting paths are efficiently planned. Simplifying your designs and minimizing unnecessary tool changes can greatly enhance the speed and precision of the routing process. This not only boosts efficiency but also reduces the chances of errors during production, ultimately leading to better results for your finished products.

Key Factors Influencing CNC Router Performance and Precision

Optimizing a CNC router for maximum efficiency and precision hinges on several key factors that influence its performance. One primary element is the quality of the machine components, including the spindle, motors, and linear guides. According to a report by the International Society of Automation (ISA), machines with higher-quality components can achieve up to 20% greater precision in machining applications. This can result in tighter tolerances and improved finish quality, which are essential for industries such as aerospace and automotive manufacturing.

Another critical factor is the software used to control the CNC router. Advanced software solutions can enhance toolpath optimization and reduce machining time by as much as 30%, as highlighted in a study by the Manufacturing Technology Centre. By utilizing intelligent algorithms that analyze the geometry of the workpiece, operators can significantly decrease cycle times while maintaining, or even improving, the precision of the final product. Moreover, regular maintenance and calibration of the machine also play a vital role, as even slight misalignments can negatively affect both efficiency and accuracy, leading to increased production costs and material waste.

Essential Maintenance Tips to Keep Your CNC Router in Top Shape

To maintain the efficiency and precision of your CNC router machine, consistent and thorough maintenance is essential. According to a 2022 report by the Association for Manufacturing Technology, machines that undergo regular maintenance can experience up to a 30% increase in productivity. Keeping your CNC router in top shape not only extends its lifespan but also ensures the accuracy of your work, leading to better quality output.

One critical tip for maintaining your CNC router is to regularly clean and lubricate all moving parts. Dust and debris can accumulate, leading to wear and tear on critical components. A light lubrication of the guide rails and ball screws every few weeks can significantly reduce friction, enhancing both speed and precision. Moreover, it’s recommended to inspect your machine's belts and pulleys for signs of wear. Replacing worn components promptly can prevent downtimes and costly repairs.

Additionally, regularly checking the calibration of your CNC router is vital. As components wear over time, cutting precision can diminish. Tools and materials should be calibrated as per the manufacturer's specifications, ideally at the beginning of each project. Implementing scheduled maintenance checks monthly can help identify issues early on, ensuring that your CNC router remains a reliable asset in your production line.

Software and Tooling Adjustments for Enhanced CNC Router Accuracy

When it comes to enhancing the accuracy of your CNC router machine, software and tooling adjustments play a vital role. The first step in optimizing your setup involves selecting the right software. Consider using advanced CAM (Computer-Aided Manufacturing) software that can generate more precise tool paths based on your specific design parameters. Features like automatic toolpath optimization can help reduce cutting time while ensuring that the tool follows the exact contour of the material, resulting in cleaner edges and better finishes. Additionally, regular updates to your software can introduce new algorithms that further enhance operational efficiency.

Tooling adjustments are equally important in achieving maximum precision. Make sure to use high-quality bits that are specifically designed for the materials you are cutting. Dull or inappropriate tooling can lead to inaccuracies in cuts or even damage to the material and machine. Furthermore, regularly calibrating your tools and maintaining the correct feed rates and spindle speeds are critical. This ensures that the machine operates at optimal performance levels, reducing the chance of errors and extending the lifespan of your tools. Investing time in software updates and proper tooling will yield significant improvements in both the efficiency and accuracy of your CNC routing operations.

Techniques to Minimize Waste and Maximize Material Utilization in CNC Routing

To maximize material utilization in CNC routing, it’s essential to employ strategic planning and effective techniques. One fundamental approach is to organize your cutting plans using optimized nesting algorithms. By smartly arranging the shapes you intend to cut, you can minimize excess material wastage. Software tools can automate this process, allowing for the most efficient layout that maximizes the use of available material while reducing scrap. This step is critical in improving both cost efficiency and environmental sustainability.

Another crucial technique is to choose the right tooling and operation speeds. Selecting the proper bit type for your specific material can lead to cleaner cuts and reduced waste. Additionally, adjusting feed rates and spindle speeds according to the material characteristics can enhance precision while minimizing the possibility of errors. Regular maintenance of the CNC router ensures that all components function at peak efficiency, further helping to maintain accuracy in cuts and limiting excess material usage. Implementing these strategies not only streamlines production but also contributes to the overall efficiency of your CNC routing operations.

Optimization of CNC Router Machine Efficiency

This bar chart represents the time allocation for different processes in operating a CNC router machine. Optimizing these areas can lead to improved efficiency and precision in production. Aim to minimize idle time and setup time while maximizing cutting time for better material utilization.

Related Posts

-

China's Intelligent Manufacturing Revolutionizes the Global Market for Best CNC Router Machines

-

Unveiling the Technical Specifications of the Best CNC Machine for Precision Engineering

-

How to Choose the Best CNC Wood Carving Machine: A Comprehensive Tutorial for Buyers

-

7 Amazing Features of the Best 3D CNC Machine You Need to Know

-

Future Market Insights on Best Engraving Machine and How to Choose the Right One for Your Business

-

Unlocking the Future of Best CNC Machine Industrial in 2025 Strategies for Global Buyers