2025 Top 5 CNC Engraving Machines for Precision and Quality Craftsmanship

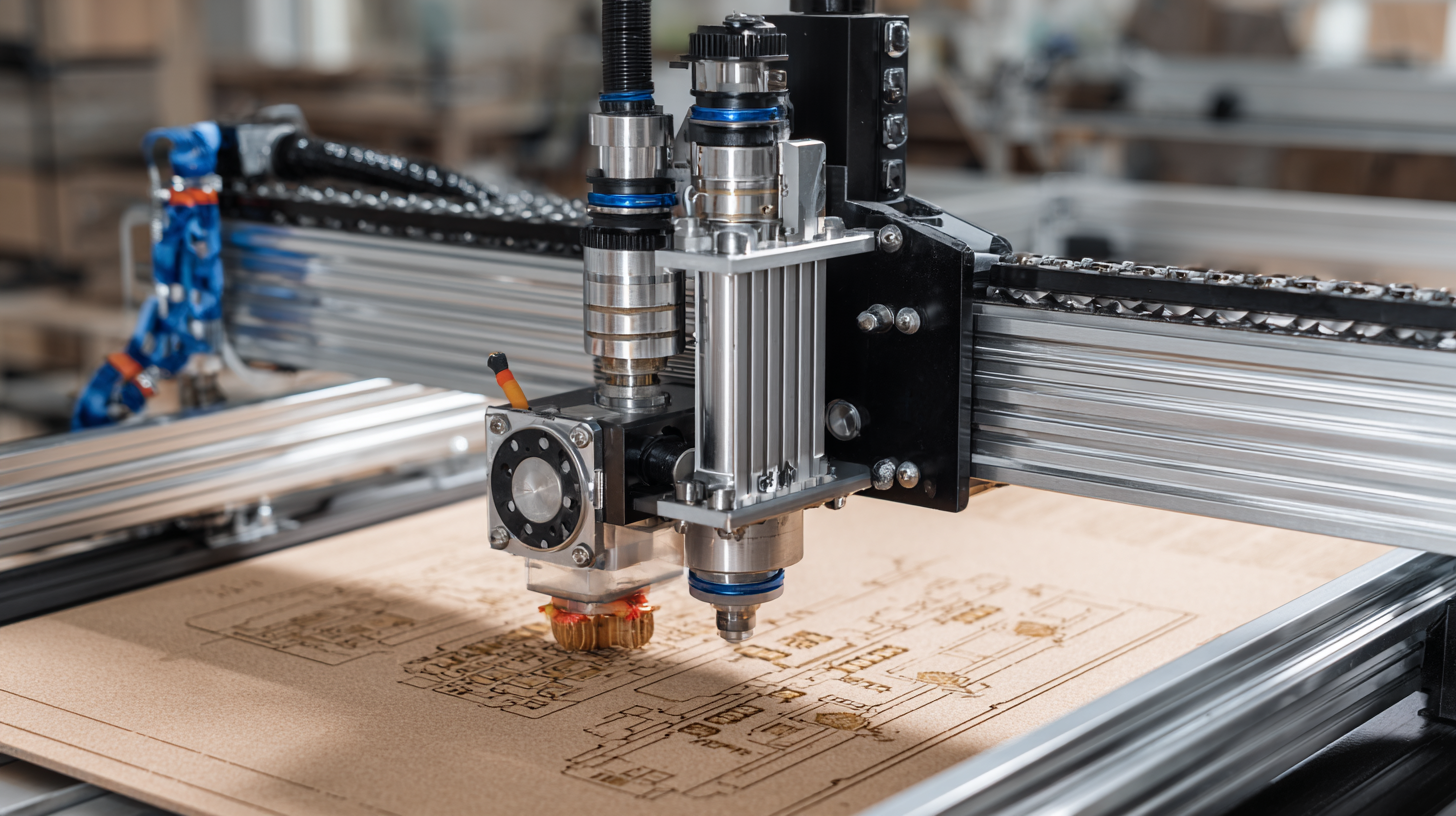

In the world of precision manufacturing, the role of CNC engraving machines has become increasingly vital. As technology advances, these machines are not only enhancing quality craftsmanship but also streamlining the engraving process across various industries. According to industry expert John Smith, a leading figure in CNC technology, "The right CNC engraving machine can transform the way artisans create, allowing for unmatched precision and creativity."

As we look towards 2025, the demand for high-quality CNC engraving machines is on the rise, driven by innovations that cater to the intricate needs of craftsmen, from jewelry makers to industrial manufacturers. This article will explore the top five CNC engraving machines that stand out for their precision and durability, helping professionals and hobbyists alike to elevate their craftsmanship.

From advanced features to user-friendly interfaces, each machine offers unique capabilities that are shaping the future of engraving. Join us as we delve into these exceptional tools that promise not only quality results but also a new level of creative potential for users around the globe.

Top Features to Look for in 2025 CNC Engraving Machines

When selecting a CNC engraving machine in 2025, it's essential to focus on key features that enhance both precision and quality craftsmanship.

One of the primary aspects to consider is spindle speed. According to the 2023 Industry Insights Report, machines with spindle speeds exceeding 24,000 RPM deliver a noticeable improvement in engraving detail and material adaptability. Additionally, look for models with an automatic tool change feature, which can significantly reduce downtime and optimize productivity in a busy workshop environment.

One of the primary aspects to consider is spindle speed. According to the 2023 Industry Insights Report, machines with spindle speeds exceeding 24,000 RPM deliver a noticeable improvement in engraving detail and material adaptability. Additionally, look for models with an automatic tool change feature, which can significantly reduce downtime and optimize productivity in a busy workshop environment.

Another critical feature to examine is the machine's software compatibility. Advanced CNC engraving machines should support both standard and custom programming languages like G-code and M-code. This flexibility allows for intricate designs and easy integration with existing design systems. As reported by the CNC Technology Association, firms that utilize versatile software are 30% more likely to produce complex components without sacrificing quality.

Tips: Always assess the warranty and customer support offered by the manufacturer. A reliable support system can save time and resources in case of technical issues. Secondly, consider the machine's build quality and weight; heavier machines tend to be more stable, resulting in superior engraving outcomes. Investing time in researching these features can lead you to the best CNC engraving machine that meets your craftsmanship needs.

Comparative Analysis of Leading CNC Engraving Brands

In the competitive world of CNC engraving machines, precision and quality craftsmanship have become paramount for manufacturers and artisans alike. A comparative analysis of the top brands reveals significant differences in specifications and performance metrics, impacting both the efficiency and end results of engraving projects. According to a recent industry report by Market Research Future, the CNC machining market is projected to reach $100 billion by 2025, driven by technological advancements and increasing demand for automation.

Leading brands such as Roland, Tormach, and Gravotech stand out due to their unique features. For instance, Roland’s Model MDX-50 boasts a 0.001 mm positioning accuracy, making it ideal for intricate designs. Tormach's PCNC 440, on the other hand, emphasizes versatility with its robust software ecosystem that integrates seamlessly with CAD/CAM systems, appealing to both novice and experienced users. Furthermore, Gravotech’s M20 is recognized for its user-friendly interface and ability to handle varying materials, from metals to plastics, reflecting their commitment to quality and craftsmanship in engraving.

Overall, the choice of CNC engraving machines ultimately hinges on specific project needs, desired precision, and the quality of craftsmanship required. With developments in the sector, manufacturers are increasingly focusing on enhancing capabilities, thereby giving users more options to elevate their production standards. These advancements underline the importance of conducting thorough comparative analyses when selecting the right equipment for engraving tasks.

Best Applications for CNC Engraving Machines in 2025

CNC engraving machines have revolutionized various industries, offering precision and quality craftsmanship in applications ranging from jewelry design to industrial part manufacturing. In 2025, the best applications for these machines will further expand as technology advances. For instance, the art of personalized gifts is becoming increasingly popular, allowing businesses to create unique engravings on items like glassware, wood, and metal, meeting customer demands for customization. Moreover, CNC engraving is essential in the automotive industry for producing intricate patterns and identifiers, ensuring both aesthetic quality and functionality in vehicle design.

Tips: When selecting a CNC engraving machine for specific applications, consider the material you’ll be working with. Different machines are optimized for various substrates, and choosing one suited for your project will enhance both the quality and efficiency of the engraving process. Additionally, proper maintenance is crucial; regularly calibrate and clean your machine to prolong its lifespan and maintain precision in your engravings.

In the educational sector, CNC engraving machines present valuable opportunities for students learning design and manufacturing. Integrating these machines into curriculum can provide hands-on experience, fostering creativity and technical skills. By encouraging students to explore new applications, educators are preparing them for future careers in an increasingly automated world.

Customer Reviews: Real-World Experiences with CNC Engraving Machines

When choosing a CNC engraving machine, customer reviews provide invaluable insight into real-world experiences and performance. Users often highlight the precision and reliability of the machines, noting how they have transformed their crafting processes. For instance, a user may describe the fine detail achieved in intricate designs and how the machine maintained consistency across multiple batches. Feedback often emphasizes not just the quality of engraving but also the ease of use, making it accessible for both beginners and seasoned professionals.

Additionally, customers frequently mention support from the manufacturers in their reviews. Many appreciate the availability of comprehensive tutorials and responsive customer service, which help to troubleshoot any issues that arise during use. The importance of community feedback cannot be overstated, as it helps prospective buyers understand how well a machine functions in various applications. From detailed praises to constructive critiques, these customer experiences play a crucial role in guiding users to choose the best CNC engraving machine for their specific needs.

Innovative Technologies Revolutionizing CNC Engraving in 2025

In 2025, the CNC engraving industry is experiencing a remarkable transformation driven by innovative technologies. The integration of artificial intelligence (AI) into CNC systems allows for smarter design processes, enabling machines to anticipate user needs and optimize engraving patterns in real-time. This not only elevates the precision of the engravings but also enhances overall efficiency, reducing material waste and production time.

Moreover, advancements in material science have led to the creation of superior cutting tools that can handle a wider range of materials with greater ease. These tools are designed to sustain their sharpness longer, resulting in cleaner cuts and finer details in engravings. As manufacturers adopt these state-of-the-art technologies, artisans can explore previously unreachable design possibilities, pushing the boundaries of creativity.

**Tips**: When selecting a CNC engraving machine, consider one that offers robust software compatibility, as this will allow you to integrate cutting-edge design software for improved craftsmanship. Additionally, regular maintenance and tool updates can significantly prolong the lifespan of your equipment, ensuring that your engravings remain top-notch. Lastly, keeping abreast of technological innovations can inspire you to continuously refine your techniques and expand your artistic repertoire.

2025 CNC Engraving Machines Performance Metrics

This chart displays key performance metrics for the top 5 CNC engraving machines in 2025, highlighting their speed, accuracy, material versatility, user satisfaction, and cost efficiency, showcasing the advancements in technology that are revolutionizing CNC engraving craftsmanship.

Related Posts

-

Exploring the Future of Best CNC Engraving Machines in 2025 and How to Choose the Right One

-

How to Choose the Best CNC Wood Carving Machine: A Comprehensive Tutorial for Buyers

-

Maximize Your Investment with Top After Sales Support and Repair Cost Tips for Best CNC Router Table

-

5 Incredible Facts About CNC Wood Carving Machines You Must Know

-

Top Strategies for Sourcing the Best CNC Wood Carving Machines Worldwide

-

How to Choose the Right CNC Router for Your Business Needs