Exploring the Top Alternatives to the Best CNC Laser Engraver for Your Business Needs

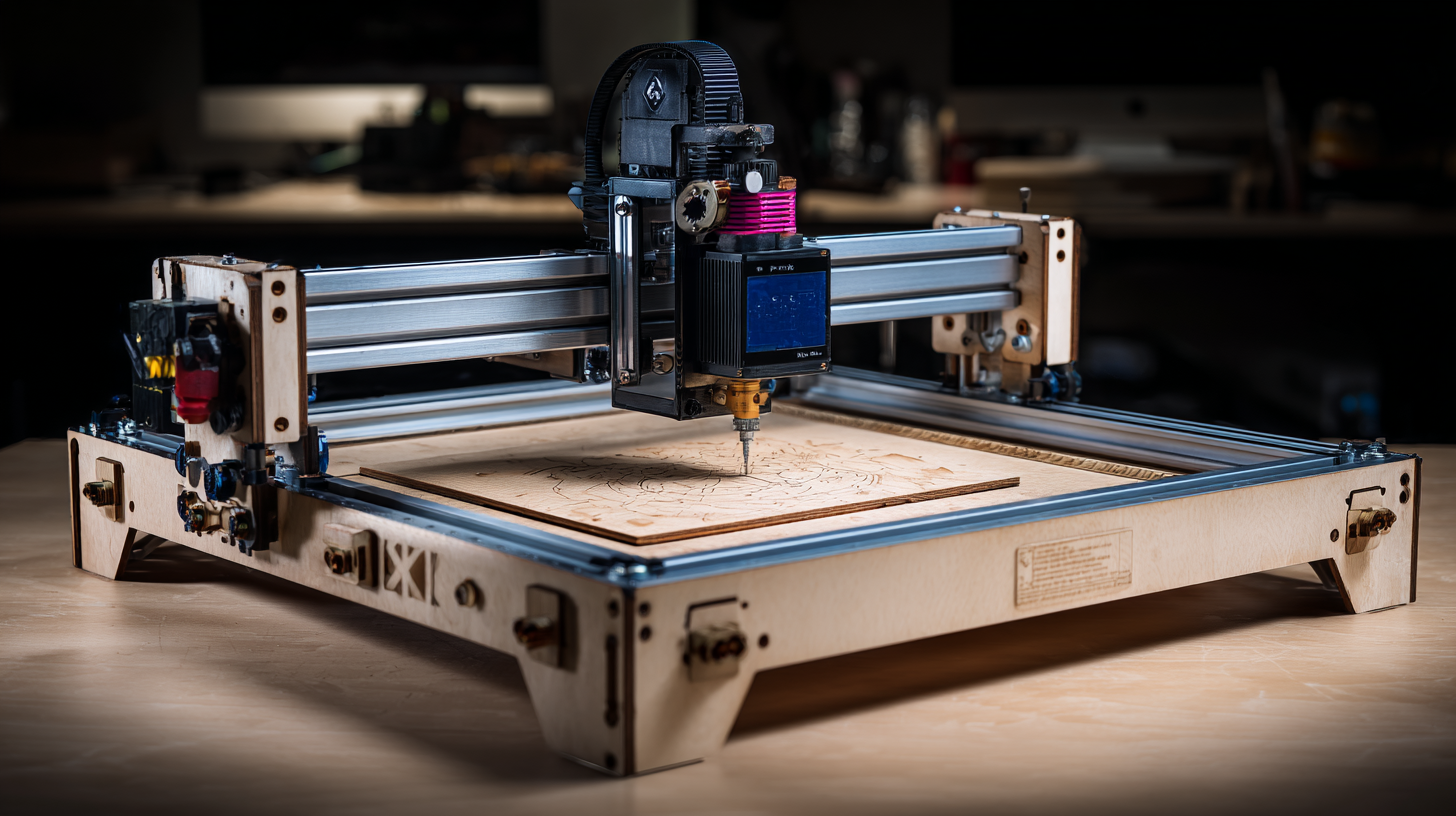

As businesses increasingly seek to enhance their production capabilities and meet customer demands, the implementation of a CNC laser engraver has emerged as a pivotal solution in various industries, including manufacturing, sign-making, and crafts.

According to a recent report from Grand View Research, the global laser engraving market is expected to reach $7.47 billion by 2025, highlighting the growing reliance on precision laser technologies. However, not all businesses may find that a CNC laser engraver is the optimal choice for their specific needs; limitations such as cost, maintenance, and operational complexity can deter potential users.

According to a recent report from Grand View Research, the global laser engraving market is expected to reach $7.47 billion by 2025, highlighting the growing reliance on precision laser technologies. However, not all businesses may find that a CNC laser engraver is the optimal choice for their specific needs; limitations such as cost, maintenance, and operational complexity can deter potential users.

This blog will explore some of the top alternatives to the best CNC laser engraver available in the market, providing insights into various solutions that cater to different business needs, efficiency levels, and budget constraints. Whether you're a startup or an established enterprise, understanding these alternatives can empower you to make informed decisions that drive your engraving projects forward.

Exploring the Rapid Growth of the CNC Laser Engraving Market by 2025

The CNC laser engraving market is poised for significant growth, projected to reach approximately $5.4 billion by 2025. This surge is driven by increasing demand across various industries, including manufacturing, electronics, and personalized gifts. According to a recent report by MarketsandMarkets, the laser engraving segment is expected to witness a compound annual growth rate (CAGR) of 7.7% from 2020 to 2025, reflecting the widespread adoption of automation technology and the need for precise, efficient production methods.

Furthermore, the rise of small businesses and entrepreneurs seeking custom solutions is amplifying this growth trend. The versatility of CNC laser engravers, capable of working with materials such as wood, glass, and metal, has made them invaluable for custom projects. Companies are increasingly investing in CNC technology to remain competitive in a rapidly evolving market, focusing on quality and customization that meet specific customer demands. As consumer preferences shift towards personalized products, the CNC laser engraving sector is set to become a key contributor to overall market expansion, fulfilling both operational and creative needs.

Exploring the Top Alternatives to the Best CNC Laser Engraver for Your Business Needs - Exploring the Rapid Growth of the CNC Laser Engraving Market by 2025

| Feature | Alternative 1 | Alternative 2 | Alternative 3 |

|---|---|---|---|

| Max Engraving Area | 600 x 400 mm | 500 x 300 mm | 700 x 500 mm |

| Laser Power | 100 W | 80 W | 120 W |

| Speed | 1000 mm/s | 800 mm/s | 1200 mm/s |

| Cooling Method | Water Cooling | Air Cooling | Water Cooling |

| Software Compatibility | CorelDRAW, AutoCAD | LightBurn | RDWorks |

| Approximate Price | $2500 | $2000 | $3000 |

Key Players in the CNC Laser Engraver Industry and Their Market Strategies

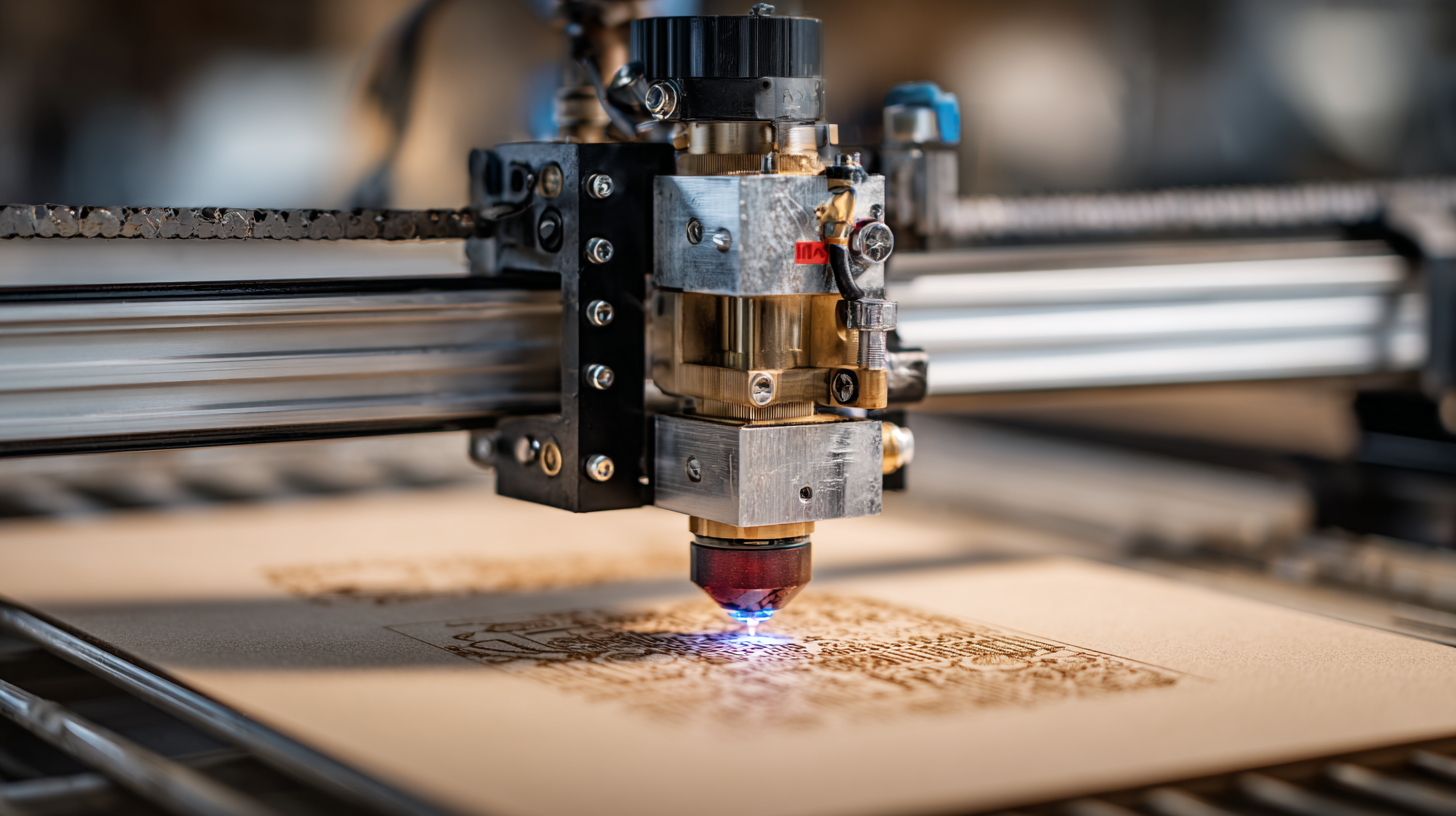

The increasing demand for efficient and precise material processing solutions has significantly boosted the adoption of fiber laser technology across various industries. Reports indicate that the global fiber laser market is projected to reach over $4 billion by 2027, with a compound annual growth rate (CAGR) of approximately 12% between 2020 and 2027. This growth is primarily driven by sectors such as automotive, electronics, and aerospace, where high precision in manufacturing and processing is critical. Companies are now turning to advanced CNC laser engravers that incorporate fiber laser technology to enhance productivity and reduce operational costs.

Key players in the CNC laser engraver industry are focusing on innovative market strategies to capture a larger share of this growing market. Many manufacturers are investing heavily in research and development to improve the efficiency and capabilities of their laser systems. For instance, the introduction of hybrid systems that combine fiber laser and traditional processing techniques is gaining traction, as they offer versatility and enhanced performance. Additionally, strategic partnerships and collaborations are being formed to leverage cutting-edge technologies and expand product offerings, ensuring that businesses can meet the escalating demands of precision and efficiency in material processing.

Comparative Analysis: Cost-Effectiveness of CNC Laser Engravers vs. Alternatives

When choosing the right equipment for your business, understanding the cost-effectiveness of CNC laser engravers compared to their alternatives is crucial. CNC laser engravers offer precision and speed, but they can come with a higher initial investment. In recent years, additive manufacturing has emerged as a viable alternative, particularly notable for its scalability and reduced waste. By layering materials, it can produce complex designs without the need for extensive tooling and setup, which can translate to significant savings for large-scale production.

However, before opting for additive manufacturing, consider these tips: Assess the specific requirements of your projects—some tasks may still benefit from the unparalleled accuracy of laser engraving. Additionally, evaluate the long-term operational costs associated with maintenance and material inputs. Lastly, always keep sustainability in mind. With the manufacturing sector increasingly scrutinizing its environmental impact, choosing methods that align with sustainable practices can offer not only cost savings but also bolster your company's reputation as a responsible player in the market.

As the landscape of manufacturing evolves, it's essential to remain informed about the latest trends. By comparing CNC laser engravers with alternatives like additive manufacturing, businesses can make educated decisions that meet both economic and environmental standards.

Comparative Analysis: Cost-Effectiveness of CNC Laser Engravers vs. Alternatives

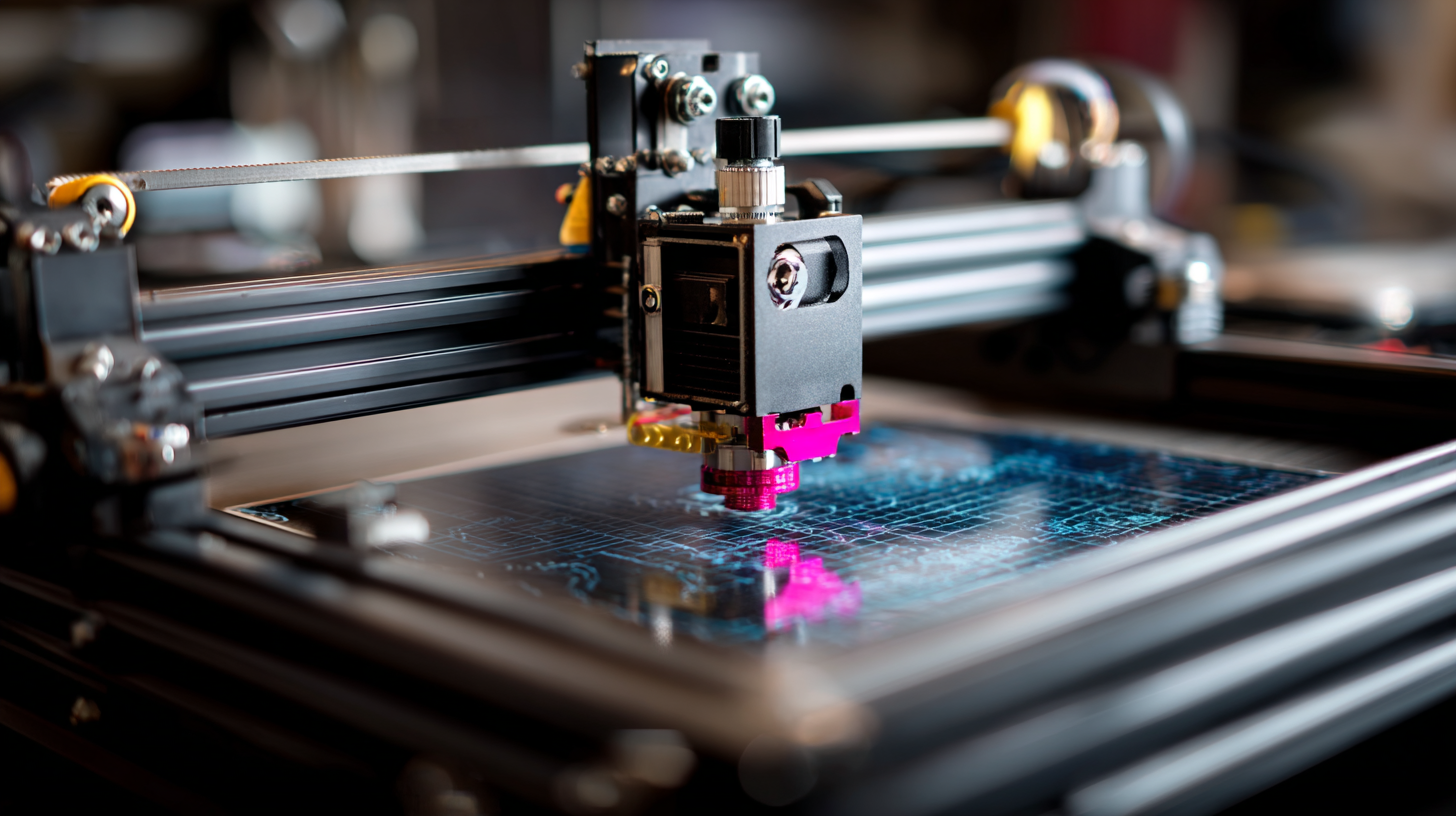

Technological Innovations Shaping the Future of CNC Laser Engraving

Technological innovations are revolutionizing the CNC laser engraving industry, paving the way for enhanced efficiency and precision. A recent report from MarketsandMarkets projects that the global CNC laser engraving market will grow from $1.43 billion in 2021 to $2.61 billion by 2026, reflecting a robust CAGR of 12.8%. This growth is driven by advancements in laser technology and the increasing adoption of automation within various sectors. Newer laser systems are now equipped with AI-driven controls, which allow for real-time adjustments during the engraving process, leading to superior results and reduced waste.

Moreover, the integration of IoT in CNC laser engraving systems is changing how businesses operate. According to a report from ResearchAndMarkets, the IoT in manufacturing market is expected to reach $403 billion by 2025. This transition is evident through features such as remote monitoring, predictive maintenance, and enhanced data analytics, which empower businesses to optimize their operational efficiencies while minimizing downtime. The future of CNC laser engraving is not just about cutting-edge machinery; it’s also about leveraging smart technology to create a seamless workflow that meets the demands of today’s fast-paced market.

Understanding Application Sectors and Their Demand for CNC Laser Solutions

The demand for CNC laser solutions continues to rise, driven by various application sectors eager to adopt advanced manufacturing technologies. The laser marking machine market is projected to experience significant growth, propelled by innovations in product types such as Fiber Laser, CO2 Laser, and UV Laser. These technologies cater to a wide range of industries, from automotive and aerospace to electronics and medical devices. This indicates a growing need for precision manufacturing solutions tailored to specific industry requirements.

Furthermore, the CNC machines market is set to reach an impressive USD 170.4 billion by 2033, marking a substantial increase from USD 66.9 billion in 2023. This growth, at a CAGR of 9.80%, underscores the increasing reliance on CNC solutions for efficient and scalable production processes. As sectors like heavy machinery and consumer goods continue to evolve, the integration of CNC laser solutions will remain pivotal in meeting the sophisticated demands of modern manufacturing landscapes. With ongoing advancements in technology, businesses must explore the top alternatives to traditional CNC laser engravers to stay competitive and fulfill their unique operational needs.