Ultimate Guide to Choosing the Perfect Home CNC Machine for Your Projects

As the DIY and maker movements gain momentum, the demand for home CNC machines has surged significantly. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $117.1 billion by 2026, reflecting an increasing interest in personalized and precision craftsmanship at home. These versatile machines empower hobbyists and professionals alike to create intricate designs and custom projects with ease. However, selecting the perfect home CNC machine can be daunting given the plethora of options available, each catering to unique needs and skill levels. This guide aims to demystify the process of choosing a home CNC machine, providing valuable insights and expert recommendations to ensure your creative ventures are both fulfilling and successful.

Key Factors to Consider When Selecting a Home CNC Machine

When selecting a home CNC machine, several key factors should be at the forefront of your decision-making process. First and foremost, consider the size of the machine and the workspace available in your home. The scale of your projects is a significant determinant; a compact machine might be ideal for small crafts, while larger machines are better suited for extensive woodworking or metalworking tasks. Evaluating the machine's footprint and ensuring it fits comfortably within your allotted space can save you hassle down the line.

Another crucial factor is the type of materials you plan to work with. Different CNC machines are designed to handle various materials such as wood, plastic, or metal, and their compatibility can affect your project outcomes. Additionally, consider the machine’s power and speed capabilities, as these specifications will influence how efficiently you can execute your designs. Lastly, don’t overlook the availability of customer support and community resources for the CNC machine you're considering. A solid support network can provide invaluable assistance, especially for beginners navigating the learning curve of CNC machining.

Ultimate Guide to Choosing the Perfect Home CNC Machine for Your Projects - Key Factors to Consider When Selecting a Home CNC Machine

| Feature | Description | Considerations |

|---|---|---|

| Build Volume | The maximum dimensions of the material that can be machined. | Choose based on the size of your projects. |

| Spindle Power | The strength of the motor that drives the cutting tool. | Higher power allows for cutting harder materials. |

| Materials Supported | Types of materials the CNC machine can handle. | Ensure it supports the materials you plan to use. |

| Ease of Use | User-friendliness of the software and controls. | Look for intuitive interfaces and good documentation. |

| Price | The overall cost of the CNC machine. | Balance your budget with required features. |

| Customer Support | Availability of support and resources from the manufacturer. | Verify the quality of after-sales support. |

| Software Compatibility | Compatibility with design and CAD software. | Make sure it works with your preferred software. |

Understanding Different Types of CNC Machines for Home Use

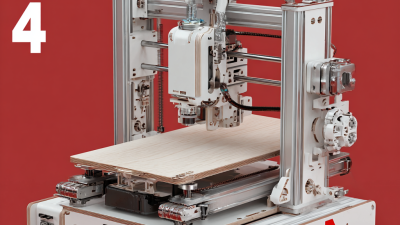

When considering home automation and personalization, CNC machines have emerged as a versatile tool for hobbyists and makers. These machines, which range from desktop models to larger units, all serve the common purpose of transforming digital designs into physical objects. Understanding the different types available is crucial for selecting the perfect one for your projects.

The key categories of CNC machines include milling machines, routers, and laser cutters, each suited for specific tasks. Milling machines excel in creating intricate shapes and are ideal for machining hard materials. Routers, on the other hand, are great for cutting and shaping wood, plastics, and softer materials, making them popular for detailed carvings and signs. Laser cutters provide precision in engraving and cutting various materials, offering unmatched detail and versatility.

As you explore the options, consider your project needs, budget, and the materials you plan to work with. Making an informed choice in this landscape can lead to a rewarding and productive addition to your home workshop, much like the adaptable equipment that has faced changing trends in the fitness market. Whether for crafting, prototyping, or DIY projects, finding the right CNC machine can inspire creativity and innovation.

Essential Features to Look for in a Home CNC Machine

When choosing a home CNC machine, there are essential features that can significantly impact your projects. First, consider the machine's size and build area. A larger workspace allows for more versatility in project dimensions, while a compact machine might fit better in a smaller workshop. Additionally, the type of materials the CNC machine can handle is crucial. Depending on whether you plan to work with wood, metal, or plastics, you need a machine that can accommodate the specific material properties.

Another important feature to look for is the machine's precision and speed. High-precision CNC machines provide better quality cuts and details, which is essential for intricate designs. Moreover, look for user-friendly software compatibility, as intuitive software can streamline your workflow, making it easier to move from design to fabrication. Finally, consider the machine's durability and support services; investing in a reliable brand can make a significant difference in your long-term satisfaction and success with your CNC projects.

Budgeting for Your Home CNC Machine Purchase: What You Need to Know

When budgeting for your home CNC machine purchase, it's crucial to consider more than just the initial cost. First, assess the total cost of ownership, which includes maintenance, software, and any necessary accessories like tooling. A machine that appears affordable upfront may lead to higher ongoing costs if it requires specialized tools or frequent repairs.

Tip: Research warranty options and customer support availability. This can have a significant impact on your overall budget, as machines with better support can help you avoid costly downtime due to issues.

Another important factor is to think about the projects you plan to undertake. The complexity and material of your projects can influence the type of CNC machine that best fits your needs. Budgeting for materials and upgrades is essential, as investing in quality tools can save you money in the long run.

Tip: Consider setting aside an additional 20% of your budget for unexpected expenses. This will help ensure that you remain within your financial limits while still being able to afford any necessary adjustments or improvements as you dive into your CNC projects.

Tips for Maintaining and Optimizing Your Home CNC Machine Performance

When it comes to maintaining and optimizing your home CNC machine, regular upkeep is key to ensuring longevity and peak performance. First, make sure to clean your machine frequently. Dust and debris can accumulate on vital components, leading to precision issues. A simple routine of wiping down surfaces and ensuring the work area is tidy will go a long way in preserving your machine's functionality.

Additionally, lubricate moving parts as recommended by the manufacturer; this reduces friction and wear, ultimately extending the lifespan of your machine.

Another important aspect of optimizing performance is calibrating your CNC machine. Regularly check the alignment and squareness of the components, as even minor misalignments can affect the quality of your projects. Invest in quality measuring tools to aid in this process, and don’t hesitate to refer to the user manual for specific calibration guidelines. Lastly, consider upgrading software or firmware periodically to take advantage of new features and improvements that can enhance your machine's capabilities.

With proper maintenance and optimization strategies, you can ensure that your home CNC machine remains a reliable and efficient tool for all your creative projects.

Related Posts

-

Unlocking the Future of Best CNC Machine Industrial in 2025 Strategies for Global Buyers

-

7 Amazing Features of the Best 3D CNC Machine You Need to Know

-

Unveiling the Technical Specifications of the Best CNC Machine for Precision Engineering

-

Exploring the Future of Best CNC Engraving Machines in 2025 and How to Choose the Right One

-

Top Strategies for Choosing the Best CNC Router for Your Business Needs

-

China's Premier CNC Wood Cutting Machines Setting Global Standards in Quality and Innovation