Unlocking Precision: How CNC Industrial Machines Revolutionize Manufacturing Efficiency

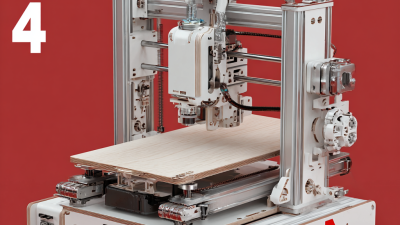

In the modern landscape of manufacturing, the quest for efficiency and precision has led to the widespread adoption of CNC industrial machines. These advanced tools are not just about automation; they represent a revolutionary leap in how products are designed and manufactured. With capabilities that range from intricate part production to large-scale fabrication, CNC industrial machines have transformed workflows by significantly reducing production times and minimizing human error. This newfound precision not only enhances the quality of the products but also streamlines operations, allowing companies to meet customer demands with agility and accuracy. As industries continue to evolve, understanding the implications of CNC technology becomes crucial for staying competitive. This article explores the multifaceted advantages of CNC industrial machines, highlighting their pivotal role in revolutionizing manufacturing efficiency.

Advantages of CNC Machining in Modern Manufacturing Processes

CNC machining has become a cornerstone of modern manufacturing, offering unparalleled precision and efficiency that traditional methods simply cannot match. By employing computer-controlled tools, CNC machines eliminate human error in the production process, resulting in more consistent and accurate parts. This precision is crucial in industries where tolerance levels are critical, such as aerospace and automotive, where even the slightest error can have significant consequences.

CNC machining has become a cornerstone of modern manufacturing, offering unparalleled precision and efficiency that traditional methods simply cannot match. By employing computer-controlled tools, CNC machines eliminate human error in the production process, resulting in more consistent and accurate parts. This precision is crucial in industries where tolerance levels are critical, such as aerospace and automotive, where even the slightest error can have significant consequences.

Moreover, the advantages of CNC machining extend beyond mere accuracy. The automation inherent in CNC technology enables manufacturers to significantly reduce production times, allowing for faster turnaround on projects. This efficiency translates into lower labor costs and increased productivity, as machines can operate around the clock with minimal intervention. Additionally, CNC machines are highly versatile, capable of producing complex geometric shapes that would be difficult or impossible to achieve through manual methods. As a result, manufacturers can diversify their product lines and respond quickly to changing market demands, positioning themselves competitively in an ever-evolving industry landscape.

The Role of Precision in Enhancing Product Quality and Consistency

Precision plays a pivotal role in the manufacturing sector, directly impacting product quality and consistency. CNC (Computer Numerical Control) industrial machines are at the forefront of this transformation, enabling manufacturers to achieve remarkable levels of accuracy. The use of advanced algorithms and intricately designed tooling allows CNC machines to replicate specifications with minimal deviation. As a result, manufacturers can produce components that meet stringent industry standards, reducing waste and enhancing overall product life cycles.

This precision not only elevates the quality of individual products but also fosters consistency across production batches. When each piece is crafted to exacting standards, the issues of rework and variability are significantly diminished. This reliability builds consumer trust and strengthens brand reputation. Furthermore, the synergy between CNC technology and quality control methods ensures that variations are detected early in the production process, allowing for immediate corrective actions. Ultimately, the integration of precision in manufacturing processes is essential for maintaining competitive advantage in an increasingly demanding marketplace.

Cost-Effectiveness: How CNC Machines Reduce Waste and Increase Profitability

CNC (Computer Numerical Control) machines have significantly transformed the manufacturing landscape by streamlining processes and enhancing cost-effectiveness. According to a report by the 2022 Global CNC Machine Tool Market, businesses experience a waste reduction of up to 30% when utilizing CNC technology. This is attributed to the precision and repeatability that CNC machines offer, which minimizes errors and maximizes material usage. Manufacturers are increasingly adopting CNC systems not just for their accuracy, but also for their ability to adapt to varying production needs without incurring substantial overhaul costs.

In addition, a study by Deloitte revealed that companies integrating CNC technology see a profitability increase of approximately 20-25% over three years due to higher operational efficiency. The ability to automate tedious tasks frees skilled labor for more value-added activities, driving innovation while keeping operational costs low. As industries face tighter margins and growing competition, the adoption of CNC machines emerges as a strategic approach to not just reduce waste but also enhance overall profitability in modern manufacturing workflows.

Unlocking Precision: How CNC Industrial Machines Revolutionize Manufacturing Efficiency - Cost-Effectiveness: How CNC Machines Reduce Waste and Increase Profitability

| Dimension | Standard Value | Impact on Efficiency | Cost Savings (%) |

|---|---|---|---|

| Setup Time | 5 hours | Reduces by 30% | 15% |

| Material Waste | 10% | Reduction to 2% | 20% |

| Cycle Time | 10 minutes | Reduces to 7 minutes | 10% |

| Labor Cost | $50/hour | Reduces by 25% | 12% |

| Overall Equipment Effectiveness (OEE) | 75% | Improves to 90% | Variable |

Impact of CNC Technology on Production Speed and Lead Times

The advent of CNC (Computer Numerical Control) technology has transformed manufacturing processes across various sectors. By automating machinery control, CNC machines facilitate precise and consistent production, which is crucial for meeting increasing consumer demands. The ability to create intricate geometries that would be nearly impossible to achieve through traditional methods has significantly boosted production speed. Manufacturers can now produce complex parts in a fraction of the time it would have taken previously, effectively reducing lead times.

Furthermore, CNC technology not only accelerates production but also enhances overall efficiency. With real-time monitoring and data analysis capabilities, manufacturers can streamline their operations, identify bottlenecks, and minimize waste. This optimization allows companies to respond swiftly to market changes, lowering costs and improving the competitiveness of their products. As a result, industries are experiencing unprecedented boosts in productivity, demonstrating the profound impact of CNC machinery on the evolution of manufacturing efficiency.

Unlocking Precision: The Impact of CNC Technology on Production Speed and Lead Times

This chart illustrates the dramatic improvements in production speed and lead times in manufacturing industries that have adopted CNC technology. The data demonstrates how CNC machines have enhanced efficiency over the years.

Future Trends in CNC Machines and Their Potential for Industry Evolution

The CNC machine market is on an impressive growth trajectory, expected to reach a value of $77 billion by 2024, with a compound annual growth rate (CAGR) of 5.5% driven primarily by the rising demand for high-precision and multi-axis machining centers. This evolution in the industry is being significantly influenced by advancements in technology such as artificial intelligence (AI), which is transforming traditional production methodologies. As AI continues to redefine the landscape, it enhances the machines' accuracy and efficiency, allowing manufacturers to meet the soaring demands for customization and production speed.

Moreover, the broader manufacturing sector is witnessing a digital revolution fueled by the Internet of Things (IoT) and Industry 4.0 principles. These innovations are not just increasing productivity; they are also reshaping the entire labor market. By 2030, the integration of these technologies into CNC operations is expected to pave the way for more intelligent production networks. This shift is leading to predictive maintenance strategies that minimize downtime, streamline workflows, and ultimately redefine what is possible in precision engineering. As we approach 2025, the landscape of CNC machining will undoubtedly be marked by these transformative trends, heralding a new era of manufacturing efficiency.

Related Posts

-

Unveiling the Technical Specifications of the Best CNC Machine for Precision Engineering

-

Unlocking the Future of Best CNC Machine Industrial in 2025 Strategies for Global Buyers

-

Top Strategies for Choosing the Best CNC Router for Your Business Needs

-

What is a CNC Industrial Machine and How It Transforms Manufacturing

-

7 Amazing Features of the Best 3D CNC Machine You Need to Know

-

Global Leaders in Manufacturing Unveiling the Best Industrial CNC Solutions